Method for preparing primary-color bio-mechanical pulp by treating wheat straw through hot steam and biological enzyme and fully utilizing byproducts

A technology of thermal steam and mechanical pulp, which is applied in the direction of using microorganism/enzyme cellulose treatment, water/steam pretreatment, pulp by-product recovery, etc. To save energy consumption for refining, solve the shortage of raw materials, and achieve economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In a first typical embodiment of the present invention, a method for preparing biomechanical pulp and by-products fully utilized by hot steam treatment in conjunction with biological enzyme treatment is provided, and the method includes the following steps:

[0024] (1) Use the waste wheat straw after obtaining wheat grain as raw material, mix it with the wheat straw according to the liquid ratio of 1:3-1:6, add a small amount of KOH, so that the pH value of the water content of the wheat straw is 10-14, and then pass it into the hot water Water steam, the hot water steam treatment process lasts for 15-60 minutes, and the steam temperature is 100-120°C; collect lye wastewater, and collect rotten leaves and straw that cannot be used for processing;

[0025] (2) After the hot steam treatment is finished, the wheat straw is extruded and divided; the waste water in the extruded section is collected;

[0026] (3) Act on the divided wheat straw and the alkaline biological com...

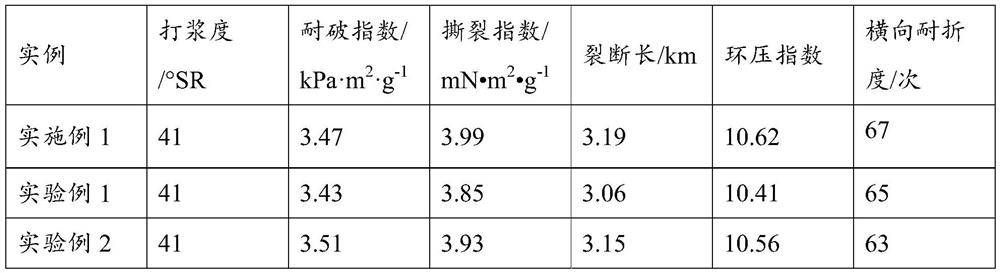

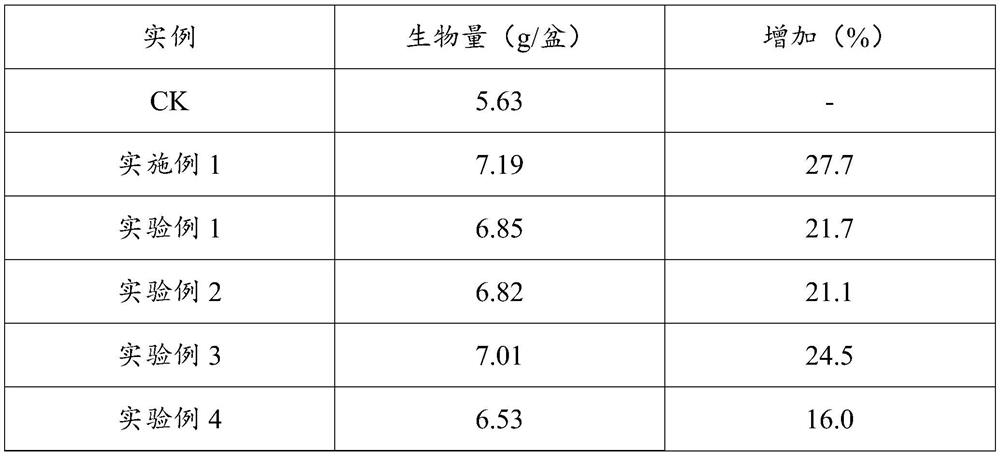

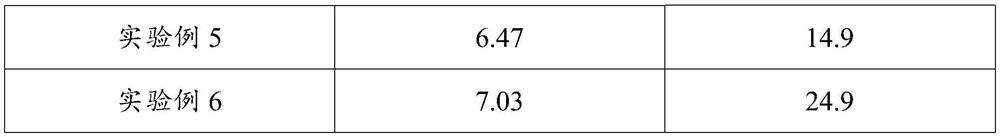

Embodiment 1

[0046] Example 1: A preparation method for fully utilizing biomechanical pulp and by-products through hot steam treatment and biological enzyme treatment. This example prepares wheatgrass-colored biomechanical pulp and simultaneously prepares biomass compound fertilizer.

[0047] (1) Cut the air-dried wheat straw after physical selection and dedusting into 5cm-long spare raw materials, put it into the wheat straw processor or reaction kettle, mix the wheat straw according to the liquid ratio of 1:5 (g / mL), and add A small amount of alkali KOH, adjust the pH value of the water content of the wheat straw at 14; collect the rotten leaves and straw that cannot be used for processing;

[0048] (2) Feed hot water steam at a temperature of 110°C for 20 minutes to dissolve a small amount of hemicellulose, lignin, pectin and other substances in the wheat straw, soften the wheat straw with hot saturated water, and soften the water content of the wheat straw at the end of the treatment T...

Embodiment 2

[0056] Example 2: A preparation method for fully utilizing biomechanical pulp and by-products through hot steam treatment and biological enzyme treatment. This example prepares wheatgrass color biomechanical pulp and simultaneously prepares biomass compound fertilizer.

[0057] (1) Cut the air-dried wheat straw after physical selection and dedusting into 4cm-long spare raw materials, put it into the wheat straw processor or reaction kettle, mix the wheat straw according to the liquid ratio of 1:4 (g / mL), and add A small amount of alkali KOH is used to adjust the pH value of the wheat straw to 14; the rotten leaves and straws that cannot be processed and used are collected.

[0058] (2) Feed hot water steam at a temperature of 100°C for 30 minutes to dissolve a small amount of hemicellulose, lignin, pectin and other substances in the wheat straw, soften the wheat straw with hot saturated water, and soften the water content of the wheat straw at the end of the treatment At a pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com