Reinforced concrete beam and section steel column end plate type connecting structure joint and construction method thereof

A technology of reinforced concrete beams and construction methods, which is applied in the direction of building structures, truss structures, columns, etc., can solve the problems of reducing the compressive performance of section steel, bond splitting damage, and alignment difficulties, and achieve changes in construction technology, Reduce the difficulty of construction and improve the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

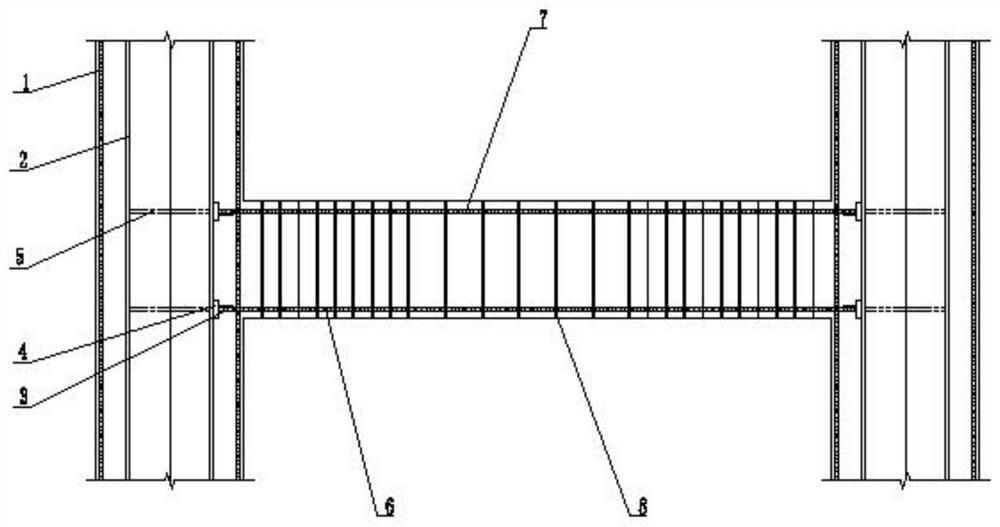

[0094] A civil building adopts a frame structure, in which part of the frame columns adopts steel columns 1, beams adopt reinforced concrete beams, beam gluten bars 7 and beam bottom bars 6 are four fourth-grade steel bars with a diameter of 25 mm, and are arranged in a single row, see figure 1 , the horizontal distance between beam gluten bars 7 and beam bottom bars 6 is 80 mm, and the corresponding upper and lower connecting end plates 4 and upper and lower stiffening plates 5 are all made of Q355B, and the width of upper and lower connecting end plates 4 is both 80 mm, then The thicknesses of the upper and lower connecting end plates 4 are:

[0095]

[0096] The construction method of the present embodiment mainly comprises the following steps:

[0097] (1) In the factory, 4 steel bar connecting sleeves 3 can be welded on the upper connecting end plate 4, and the other 4 steel bar connecting sleeves 3 can be welded on the lower connecting end plate 4, so that the reinfor...

Embodiment 2

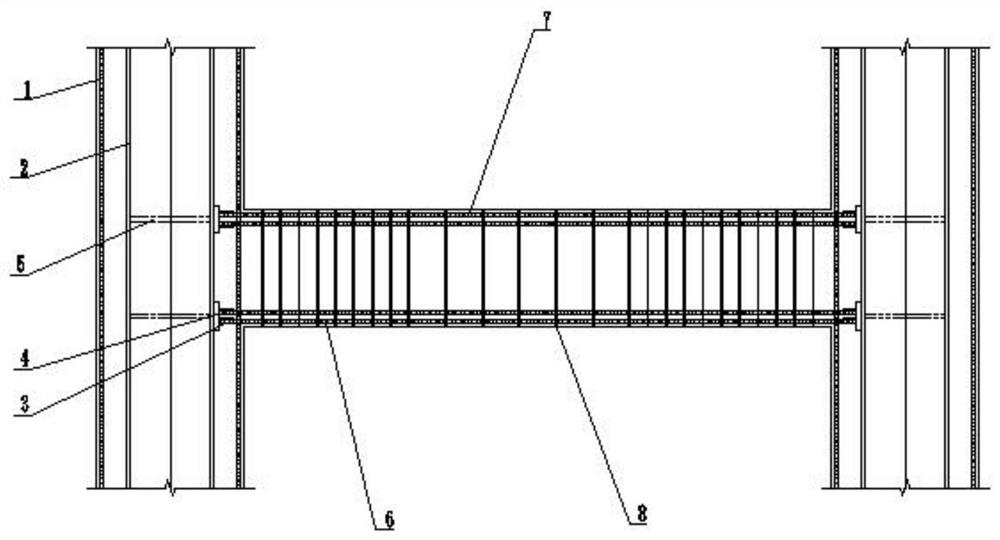

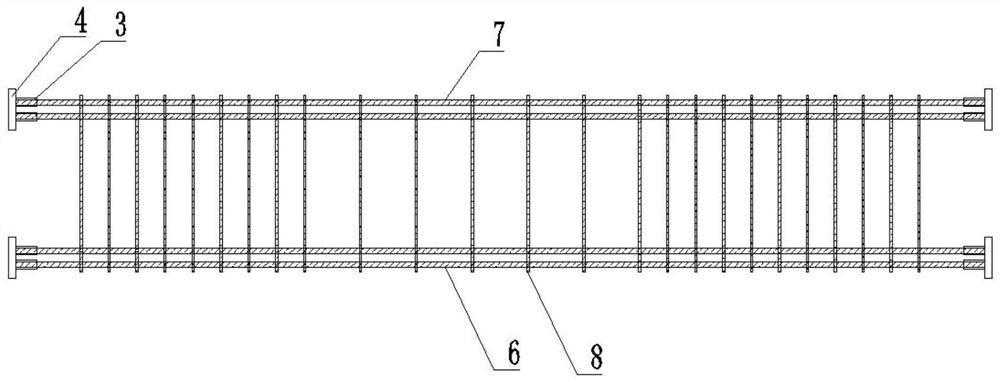

[0104] A civil building adopts a frame structure, in which part of the frame columns adopts steel columns 1, beams adopt reinforced concrete beams, beam gluten bars 7 and beam bottom bars 6 are eight fourth-grade steel bars with a diameter of 25 mm, see Figure 2~4 , double-row arrangement is adopted, the horizontal distance between the beam gluten bars 7 and the beam bottom bars 6 is 50mm, the connecting end plate 4 and the stiffening plate 5 are all made of Q355B, the vertical distance between the beam gluten bars 7 and the double-row steel bars is 50mm, and the beam bottom The vertical spacing of the double-row steel bars of rib 6 is also 50mm, so the thicknesses of the upper connecting end plate 4 and the lower connecting plate are both:

[0105]

[0106] The construction method of this embodiment is the same as the step flow of Embodiment 1.

[0107] The number of gluten bars and bottom bars and steel bar specifications of the reinforced concrete beams in the above emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com