Self-formwork cast-in-place floor and construction method thereof

A construction method and technology of cast-in-place floor slabs, which are applied in the field of construction, can solve problems such as the inability to use cast-in-place floor slabs for construction, and achieve the effects of saving material costs and labor costs, increasing strength, and improving stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

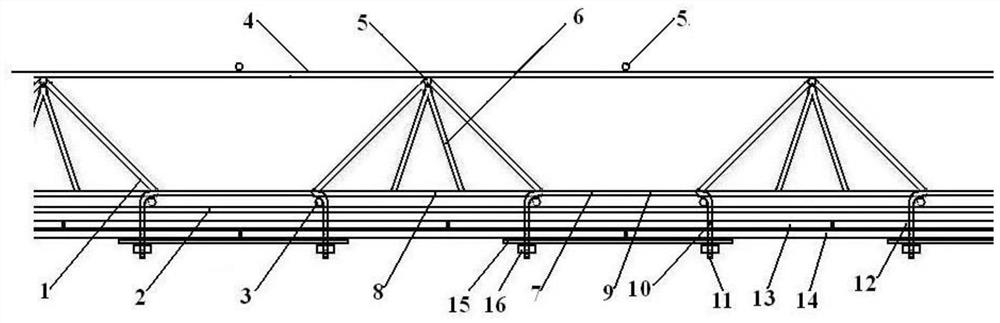

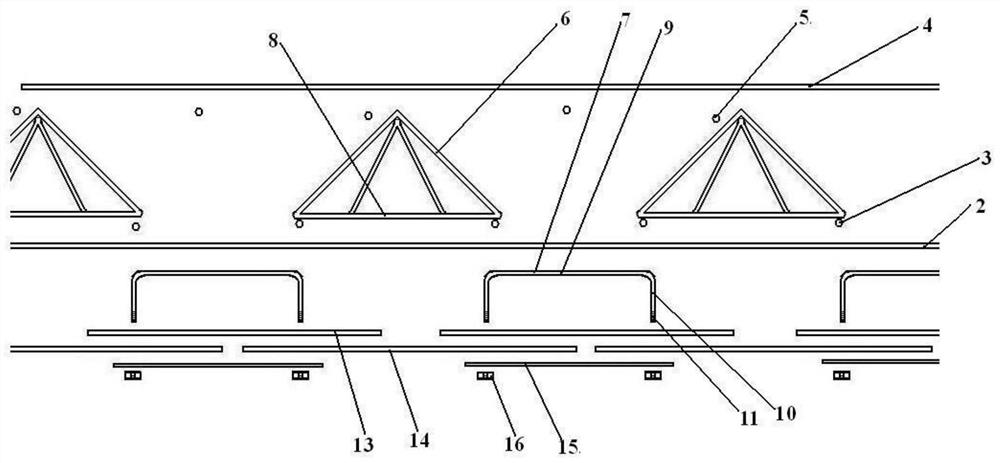

[0046] As shown in the figure, the present invention provides a construction method for self-supporting formwork cast-in-place slabs, including the following construction steps:

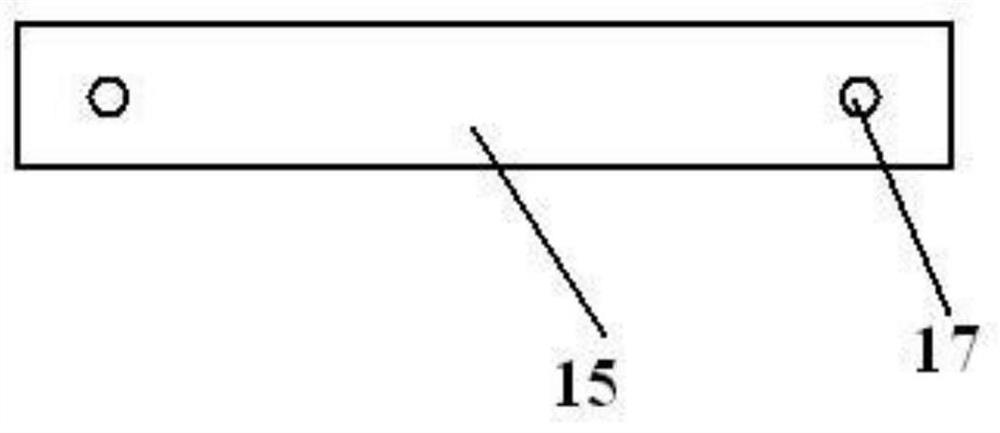

[0047] (1) Firstly, prepare steel bars, steel wire mesh, bottom formwork, side formwork, steel sheets, nuts 16 and concrete mortar.

[0048] (2) According to the design specifications, cut and make several bottom transverse bars 2, bottom longitudinal bars 3, upper transverse bars 4, and upper longitudinal bars 5 according to the design specifications.

[0049] (3) According to the design specifications, five steel bars are cut and made with steel bars for making the triangular overlapping frame 6; first, three of the steel bars are welded into a triangle, and one of the horizontal side steel bars prepared to be placed on the lower side is used as the bottom edge 8, Then set two points on the bottom edge 8, and make the position of these two points place can divide this bottom edge steel bar into thr...

Embodiment 2

[0064] On the basis of Example 1, step ⒃ is divided into two steps to pour concrete mortar, which can make the bottomless formwork system more stable, namely:

[0065] ⒃ The first step is to use concrete mortar to bury the steel wire mesh, the bottom reinforcement mesh, the bottom edge of the triangular overlapping frame 6 and the square rod 9 of the square connecting frame 7, and then vibrate and maintain until the specified design strength is reached.

[0066] ⒄Then carry out the second step of pouring, tying the steel wire mesh above the upper horizontal bar 4, and then pouring concrete mortar until the upper steel wire mesh is buried, then ramming and curing, and the construction is completed after reaching the strength.

Embodiment 3

[0068] As shown in the figure, the present invention provides a construction method for self-supporting formwork cast-in-place slabs, including the following construction steps:

[0069] Cast reinforced concrete floor slabs on the building where the beams and longitudinal beams have been built. The overhead length of the beams is 3500mm and the width is 250mm, and the overhead length of the longitudinal beams is 5000mm and the width is 250mm.

[0070] (1) Firstly, prepare steel bars, steel wire mesh, bottom formwork, side formwork, steel sheets, nuts 16 and concrete mortar. The diameter of the steel bar is 15mm, and the inner diameter of the nut is 15mm.

[0071] (2) According to the design specifications, cut and manufacture several bottom transverse bars 2 with a length of 3750mm, bottom longitudinal bars 3 with a length of 5250mm, upper transverse bars 4 with a length of 3750mm, and upper longitudinal bars 5 with a length of 5250mm.

[0072] (3) Cut and manufacture five st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com