Integrated heat storage industrial steam supply cogeneration peak regulation and frequency regulation system and operation method

A technology of cogeneration, peak regulation and frequency regulation, which is applied to cogeneration systems, heating systems, and central heating, can solve the problems of low working efficiency of air leakage systems and loud air compressor noise, and achieve good peak regulation and frequency regulation. , the effect of reducing heating costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

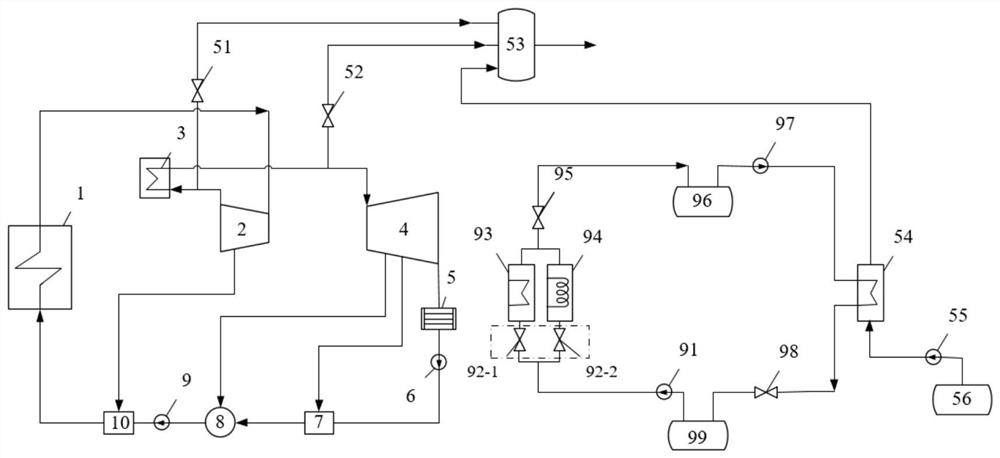

[0027] Such as figure 1 As shown, the present invention is an industrial steam supply cogeneration peak regulation and frequency modulation system with integrated heat storage, which is composed of a coal-fired power generation system, a steam supply system, and a molten salt heat storage system. The coal-fired power generation system includes a boiler 1, a steam turbine high-pressure cylinder 2. Reheater 3, medium and low pressure cylinder of steam turbine 4, condenser 5, condensate pump 6, low pressure heater 7, deaerator 8, feed water pump 9 and high pressure heater 10, steam supply system includes reheater cold section Steam extraction regulating valve 51, steam extraction regulating valve 52 in the hot section of reheater, industrial steam supply header 53, steam generator 54, water tank feed water pump 55 and steam supply water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com