LED long-afterglow composite light-emitting strip-shaped lens and light-emitting device comprising LED long-afterglow composite light-emitting strip-shaped lens structure

A technology of long afterglow luminescence and long afterglow luminous powder, which is applied to optical elements for changing the spectral characteristics of emitted light, semiconductor devices of light-emitting elements, light sources, etc. Problems such as poor directivity, to achieve the effect of reducing light energy waste, reducing matching errors, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

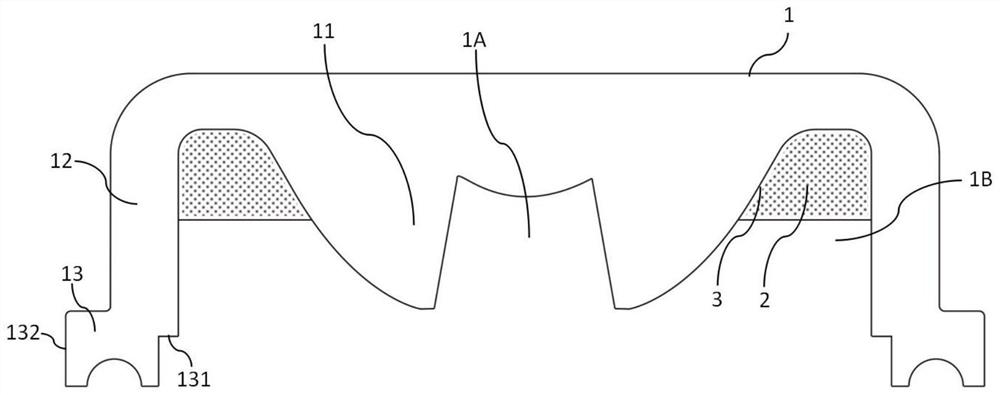

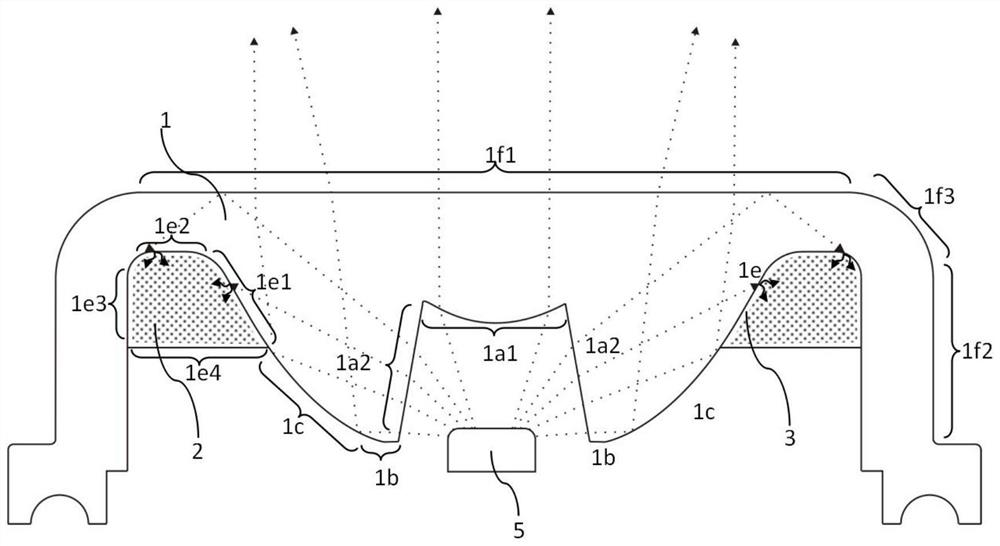

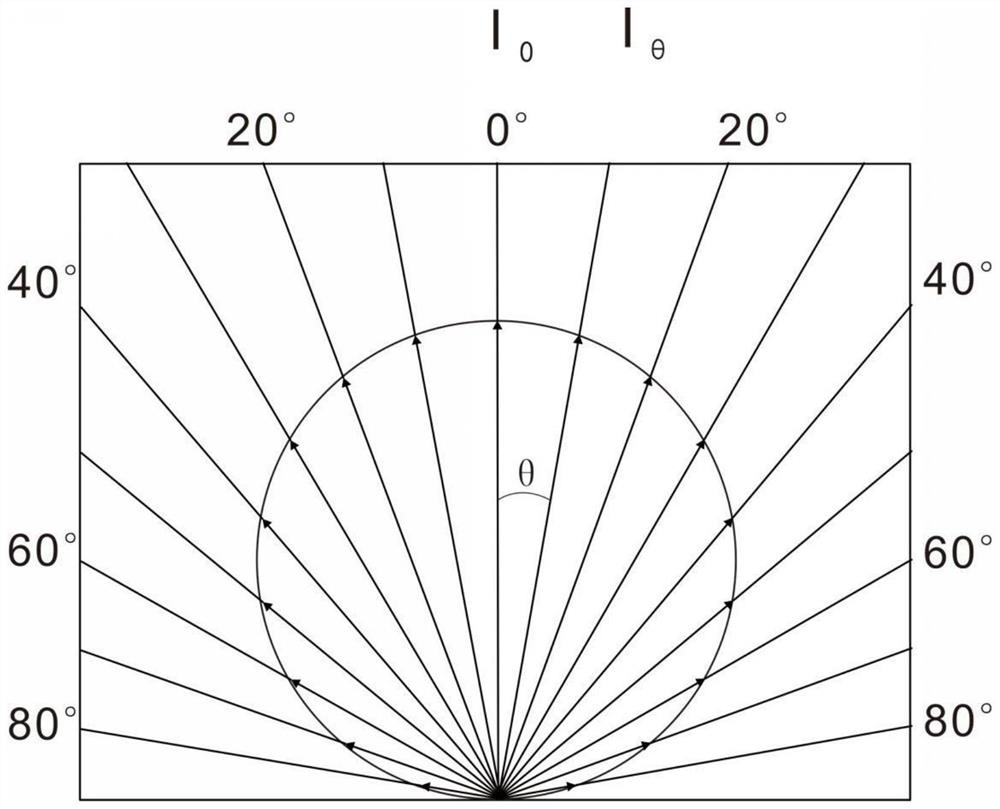

[0192] Embodiment 1 of the present invention proposes a LED long afterglow composite light-emitting strip lens with a light-gathering structure, such as Figure 22 As shown, it includes a lens body structure (110), the central optical main part of which is a bar-shaped structure whose cross-section gradually increases from bottom to top, and the center of the bottom of the central optical main part is provided with an accommodating groove for the light of the bar-shaped light source to enter (110A), the inner wall of the accommodation groove (110A) is a parabolic cylinder, and the two sides of the lens body structure (110) are provided with the optical body part (1110) connected with the middle light distribution, along the middle light distribution optical body part (1110) ) arranged in parallel, the downturned transparent surround acts as a side surround (1120), and an accommodation along the extending direction of the accommodation groove (110A) is provided between the middl...

Embodiment 2

[0212] Embodiment 2 of the present invention provides a LED long afterglow composite light-emitting strip lens with a diverging structure, such as Figure 29 As shown, it includes a lens body structure (210), the edge of the lens body structure (210) has an upturned transparent surround as a side wall portion (2120), the central optical body portion (2110) has a raised arched section, and the central The center of the bottom of the optical body part (2110) is provided with an accommodating groove (210A) capable of entering light from a bar-shaped light source. The curvature of the light incident surface (210a1) is greater than the curvature of the corresponding part of the light exit surface (210f), and an accommodation parallel to the accommodation groove (210A) is provided between the middle light distribution optical main part (2110) and the side surrounding part (2120). In the groove (210B), the long-lasting luminescent molded body (220) is formed by pouring the liquid mix...

Embodiment 3

[0219] Embodiment 3 of the present invention provides an LED long afterglow composite light-emitting strip lens with a TIR total reflection structure combined with a prism directional angle exit structure, such as Figure 35As shown, it includes a strip-shaped lens body structure (310). The lens body structure (310) is a strip-shaped structure with a transparent surround, and its central optical main body gradually increases in size from bottom to top. The bottom center of the central optical main body An accommodating groove (310A) capable of entering light from a bar-shaped light source is provided, and an intermediate light distribution optical main body (3110) conjoined with the intermediate light distribution optical main body (3110) is provided on both sides of the lens body structure (310). ) arranged in parallel, the downturned transparent surround acts as a side surround (3120), and an accommodation along the extending direction of the accommodation groove (310A) is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com