Micro-channel heat exchanger and machining method thereof

A technology of microchannel heat exchanger and processing method, applied in indirect heat exchangers, heat exchanger types, additive processing, etc., can solve the problems of low thermal efficiency of microchannel heat exchangers, easy deformation of microchannels, etc., to avoid The effect of combining unevenness, avoiding clogging of etching channels, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

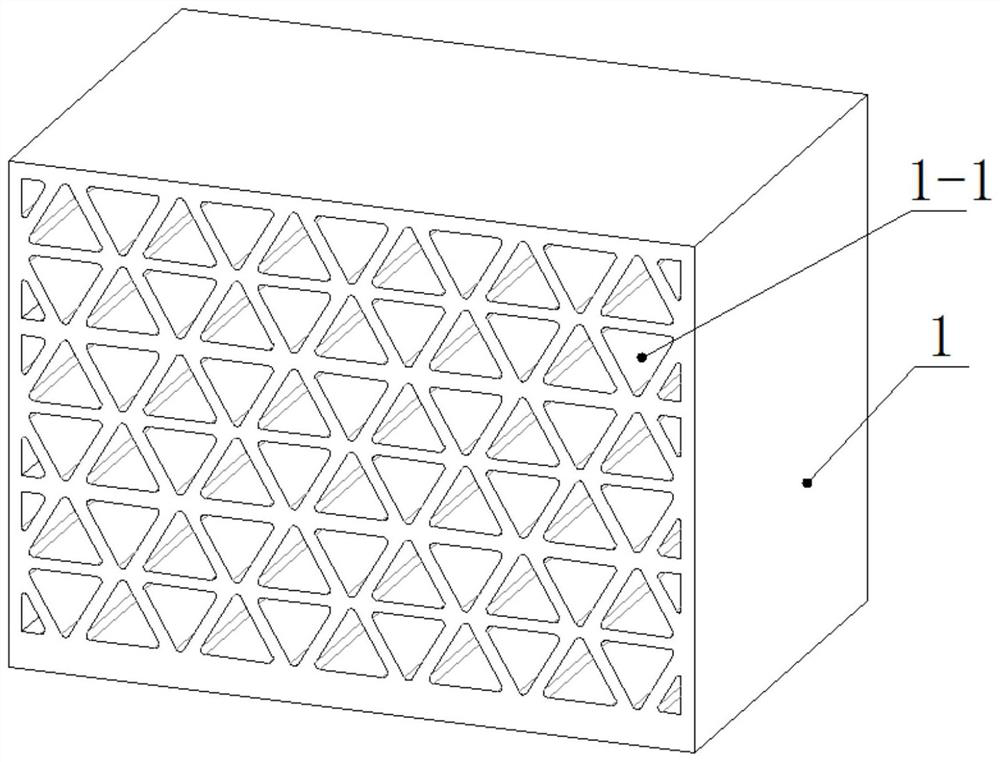

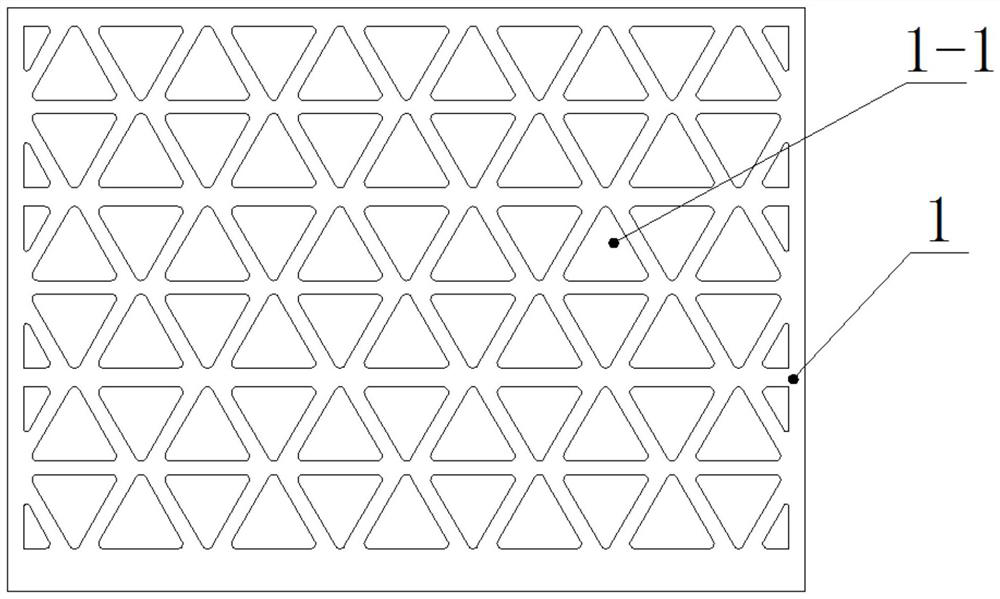

[0037] In this embodiment, the processing of the microchannel heat exchanger 1 used in the seawater working fluid heat channel for primary power generation is taken as an example. The size of the microchannel heat exchanger 1 is 100mm×100mm×100mm, and its structural diagram is as follows figure 1 , figure 2 shown.

[0038] The processing method is as follows:

[0039] 1. Through 3D unit modeling, the triangular microchannel unit 1-1 with circular arc transition is adopted. The diameter of the circumscribed circle of the triangle is 1mm. The contact area of the hot and cold aisles increases.

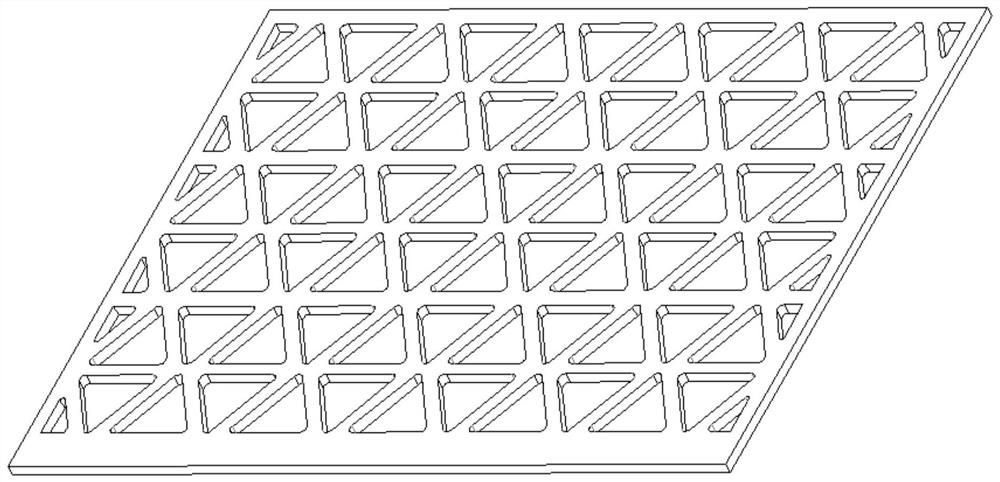

[0040] 2. Use selected area laser 3D printing for manufacturing to realize layered additive manufacturing. The layer-by-layer printing method is as follows: image 3 Shown; Use the triangular prism mandrel ceramic mandrel 2 coated with solder resist as channel support (extracted out after manufacture), described triangular prism mandrel ceramic mandrel 2 as Figure 4 As shown, the ...

Embodiment 2

[0047] In this embodiment, the processing of the microchannel heat exchanger 1 for LNG offshore cold energy power generation applied to secondary coupling power generation is taken as an example. The size of the microchannel heat exchanger 1 is 100mm×100mm×100mm, and its structural diagram is as follows figure 1 , figure 2 shown.

[0048] The processing method is as follows:

[0049] 1. Through 3D unit modeling, the triangular microchannel unit 1-1 with circular arc transition is adopted. The diameter of the circumscribed circle of the triangle is 1mm. The contact area of the hot and cold aisles increases.

[0050] 2. Use selected area laser 3D printing for manufacturing to realize layered additive manufacturing. The layer-by-layer printing method is as follows: image 3 Shown; Use the triangular prism mandrel ceramic mandrel 2 coated with solder resist as channel support (extracted out after manufacture), described triangular prism mandrel ceramic mandrel 2 as Figure ...

Embodiment 3

[0057] In this embodiment, the processing of the microchannel heat exchanger 1 used to realize high-temperature and high-pressure steam heat exchange in the field of thermal power is taken as an example. The size of the microchannel heat exchanger 1 is 100mm×100mm×100mm, and its structural diagram is as follows figure 1 , figure 2 shown.

[0058] The processing method is as follows:

[0059] 1. Through 3D unit modeling, the triangular microchannel unit 1-1 with circular arc transition is adopted. The diameter of the circumscribed circle of the triangle is 1mm. The contact area of the hot and cold aisles increases.

[0060] 2. Use selected area laser 3D printing for manufacturing to realize layered additive manufacturing. The layer-by-layer printing method is as follows: image 3 Shown; Use the triangular prism mandrel ceramic mandrel 2 coated with solder resist as channel support (extracted out after manufacture), described triangular prism mandrel ceramic mandrel 2 as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com