Oil pumping polish rod fatigue performance experiment platform under stretching and bending superposition deformation working condition

A technology for pumping polished rods and fatigue performance, which is used in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc. It can solve the problem of large gaps, large differences in the actual working conditions of pumping polished rods, and it is difficult to meet actual needs, etc. problems, to achieve controllable and adjustable results, good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

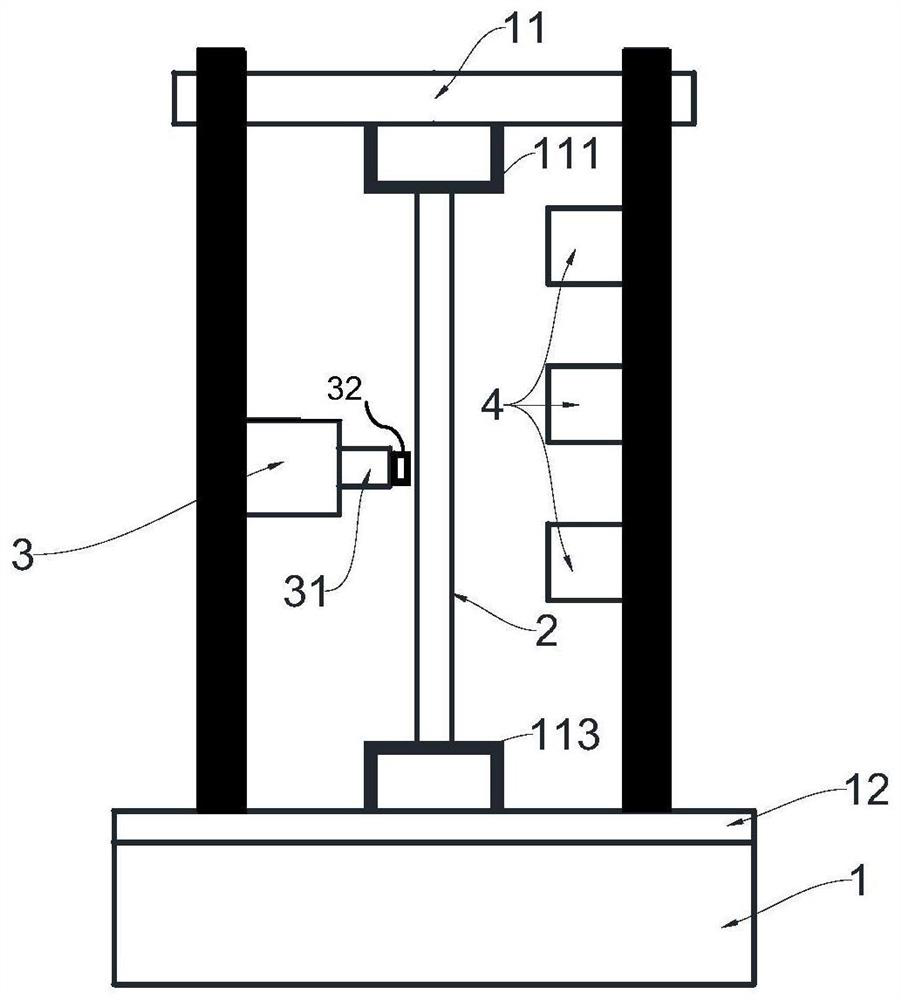

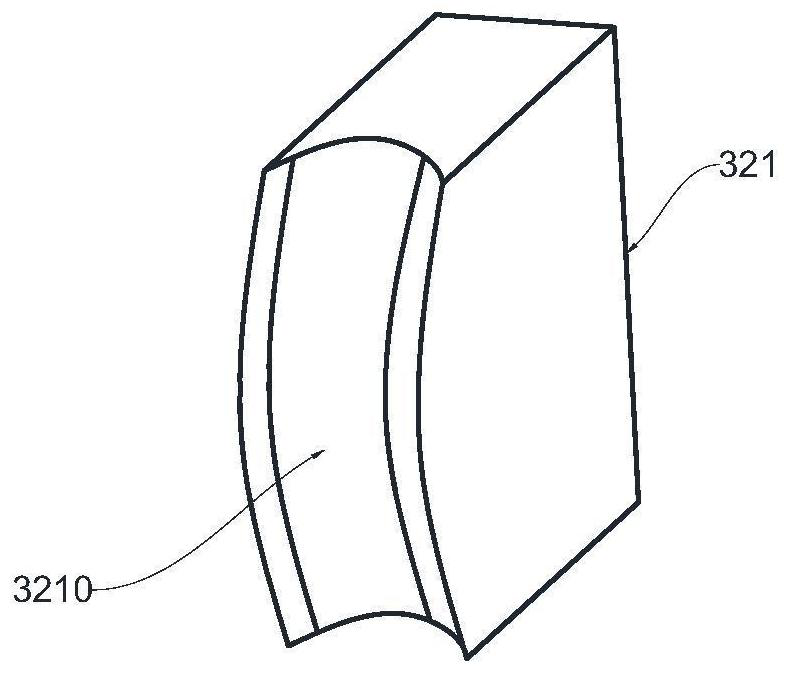

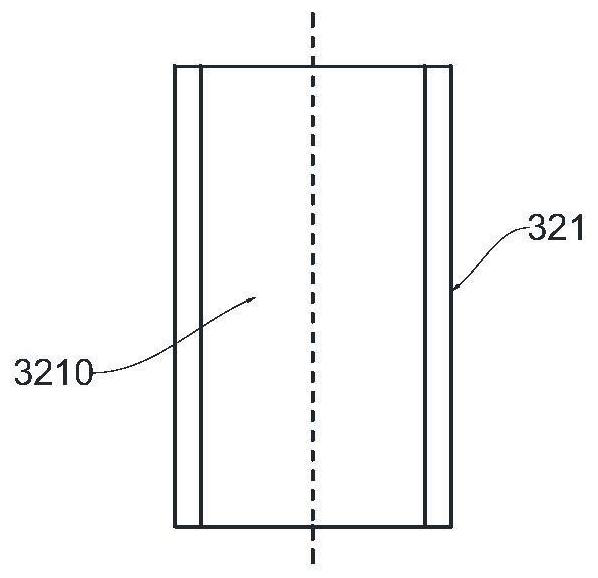

[0035] see figure 1 , according to the embodiment of the oil pumping polished rod fatigue performance experiment platform under the tensile and bending superimposed deformation conditions of the present invention, the provided embodiment includes a main frame 1, a loading system, a measurement system and a control system, and the upper part of the main frame 1 is provided with a mobile Beam 11, the lower part of the main frame 1 is provided with a fixed beam 12, the lower part of the moving beam 11 is fixedly installed with the upper clamping assembly 111 connected with the polished rod sample 2, and the loading system also includes a lateral extrusion Pressing device 3, the side of the main frame 1 is provided with the lateral pressing device 3 that can move up and down in the vertical direction, and multiple groups of cameras are also arranged on the frame directly opposite the lateral pressing device 3. Unit 4, a first servo loading mechanism is provided between the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com