Hollow-core microstructure optical fiber with angular mode selectivity

A micro-structure optical fiber, selective technology, applied in cladding optical fiber, light guide, optics, etc., can solve the problems of complex preparation process and large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

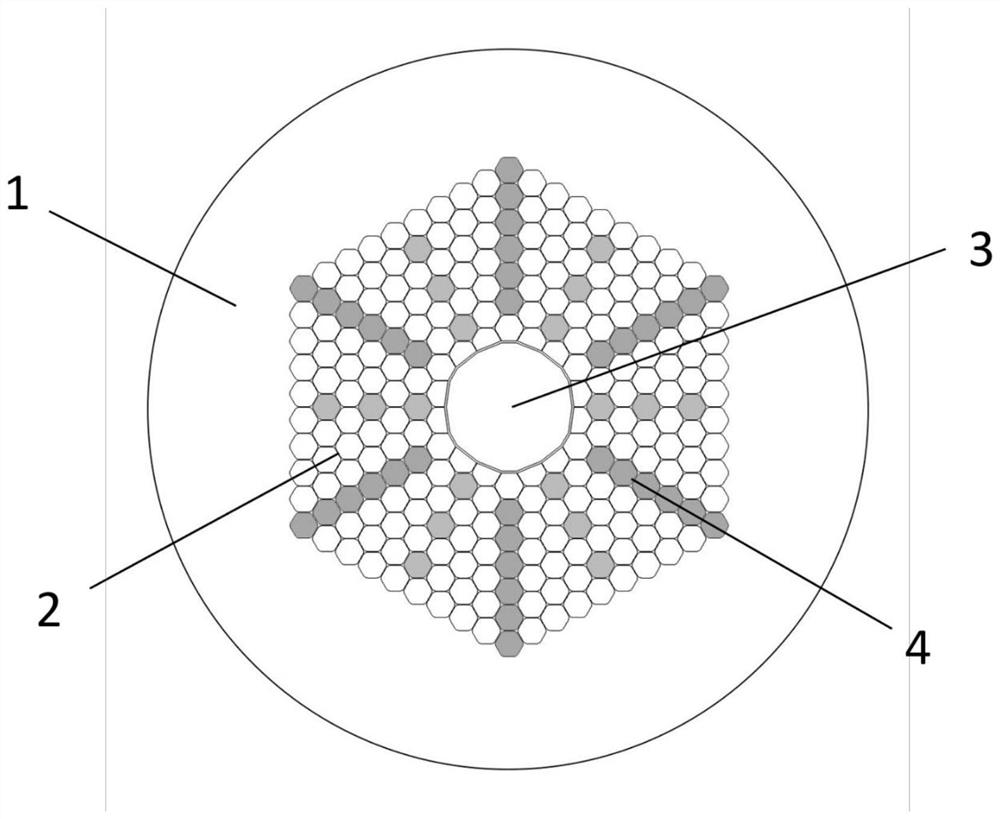

[0018] The cross-sectional structure of the optical fiber in this example is as figure 1 As shown, the matrix material 1 is included, the cladding is composed of rounded hexagonal air holes 2 on the matrix material according to the hexagonal periodic arrangement to form a hexagonal cladding structure, and the core area is a large air hole 3 . The cladding contains twelve symmetry axes with an angle of 30° to each other. The size of the air holes whose centers fall on these 12 symmetry axes in the cladding is larger or smaller than the air holes in other positions at the same time, or partially enlarged The other part shrunk, but kept the same shape.

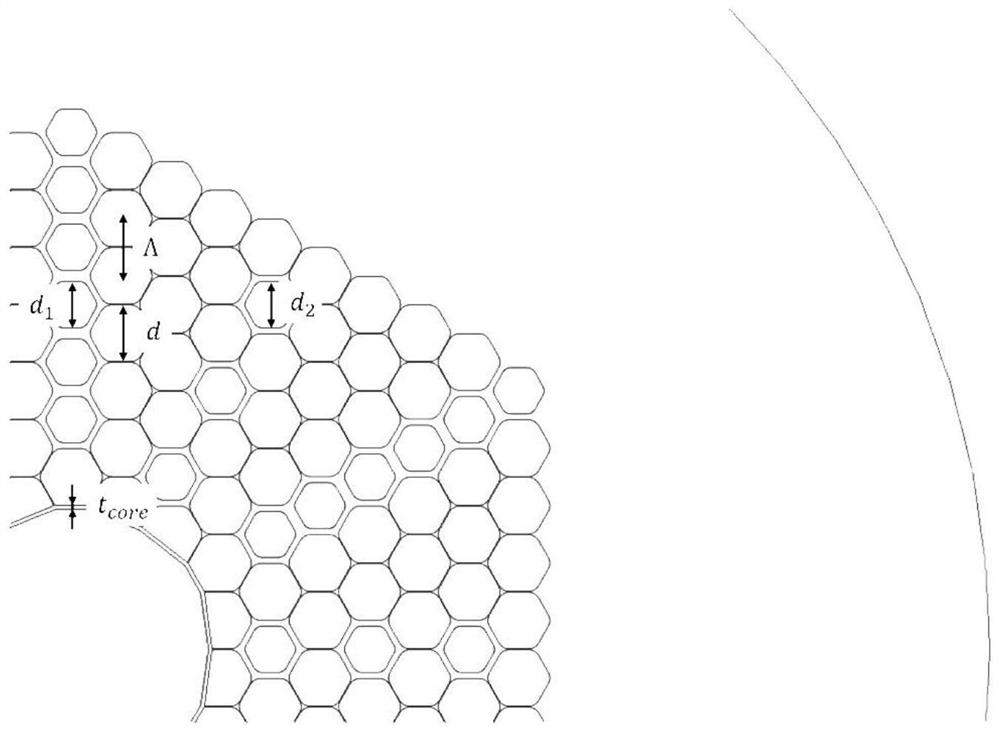

[0019] The partially enlarged figure of the cross-section of the optical fiber in the present invention is as figure 2 As shown, in this example, various parameters are set as Λ=5μm, d=0.98Λ, d 1 =0.96Λ,d 2 =0.96Λ,t core = 370nm. The fiber matrix material is quartz, and its refractive index is 1.444 at 1550nm. The air core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com