System for adjusting temperature of high-temperature gas cooled reactor cabin

A high-temperature gas-cooled reactor and reactor cabin technology, which is applied in the directions of reactors, greenhouse gas reduction, cooling devices, etc., can solve the problems of slow reduction of the temperature of the reactor cabin, unfavorable improvement of the unit economy, and influence on the maintenance of equipment in the area to which it belongs. Cooling time, reducing shutdown time, and accelerating the effect of temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

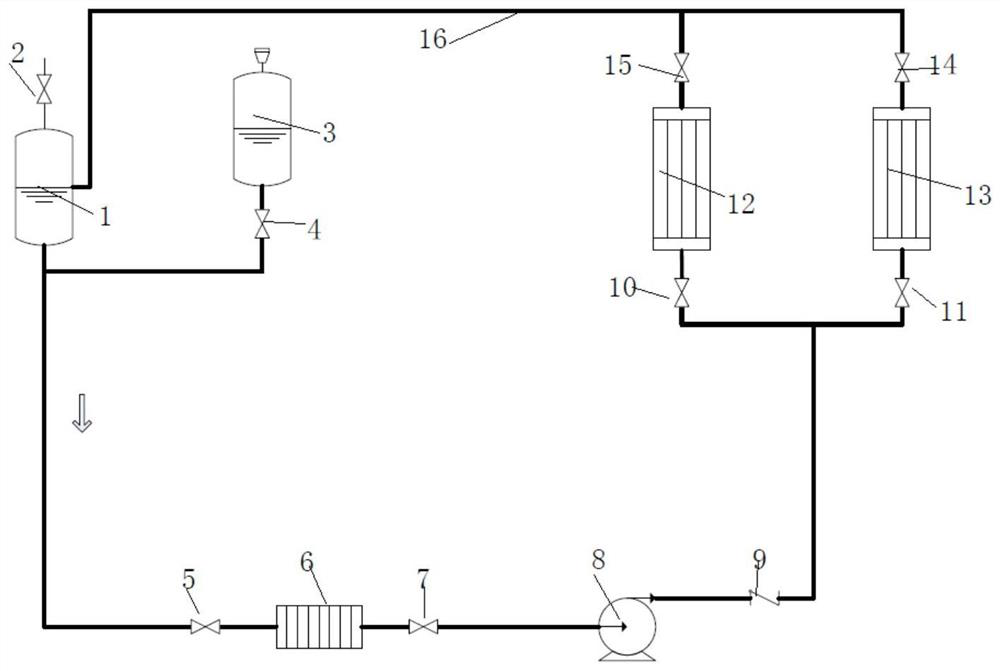

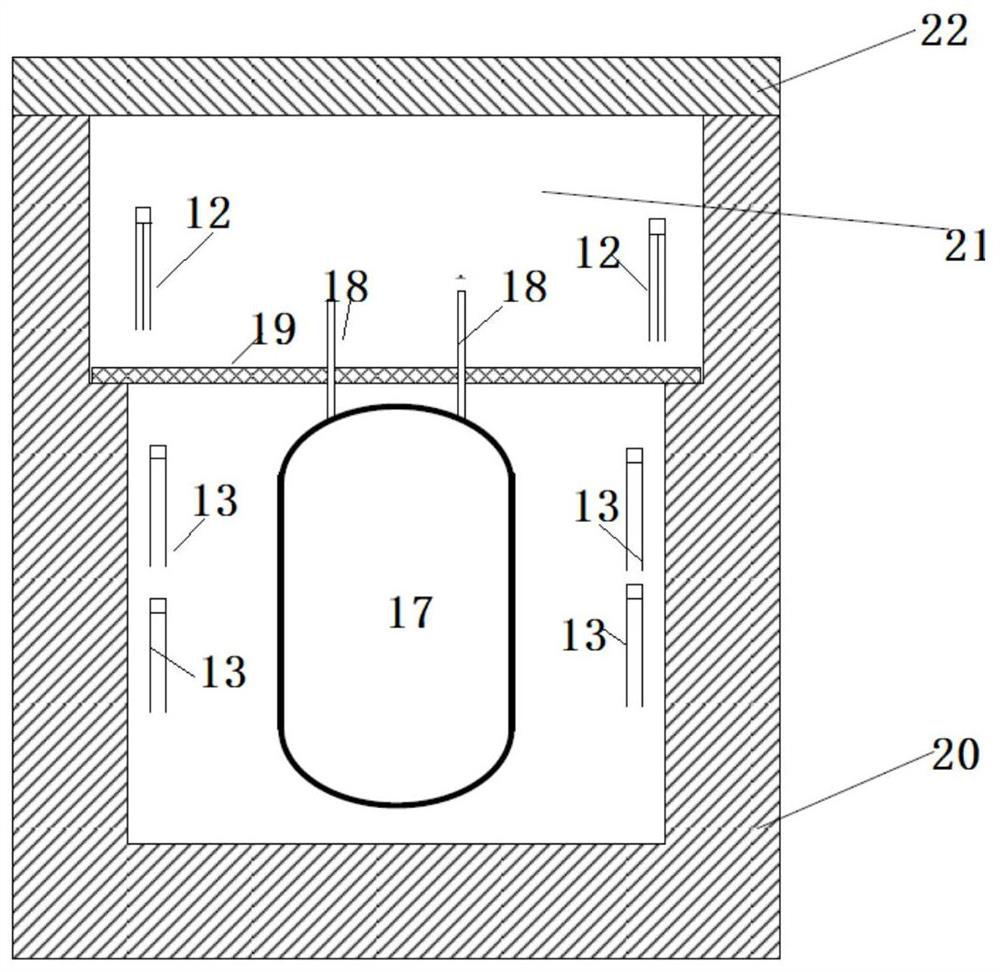

[0020] Such as figure 1 As shown, a system for regulating the temperature of the high-temperature gas-cooled reactor compartment includes a water tank 1, which communicates with one end of the heat exchanger A6 arranged in the auxiliary building through a water supply pipe and a valve B5, and the other end of the heat exchanger A6 One end communicates with one end of the pump 8 through a pipeline and valve C7, and the other end of the pump 8 is connected with one end of the check valve 9 through a pipeline. The heat exchanger B12 in the upper compartment is connected; the other is connected to the heat exchanger C13 arranged in the lower compartment of the reactor through the pipeline and the valve E11; the other end of the heat exchanger B12 is connected to the valve G15; the other end of the heat exchanger C13 is connected to the valve F14 , the valve F14 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com