Structure and method of combined stator iron core claw pole transverse magnetic flux permanent magnet brushless motor

A permanent magnet brushless motor and combined stator technology, applied in the direction of magnetic circuit shape/style/structure, manufacturing motor generators, manufacturing stator/rotor body, etc., can solve the problems affecting the accuracy and rapidity of motor drive control, motor control Problems such as complex mathematical models and motor cogging torque optimization have achieved the effect of promoting the technical level, simplifying electromagnetic calculation and performance analysis, and improving the three-dimensional magnetic circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

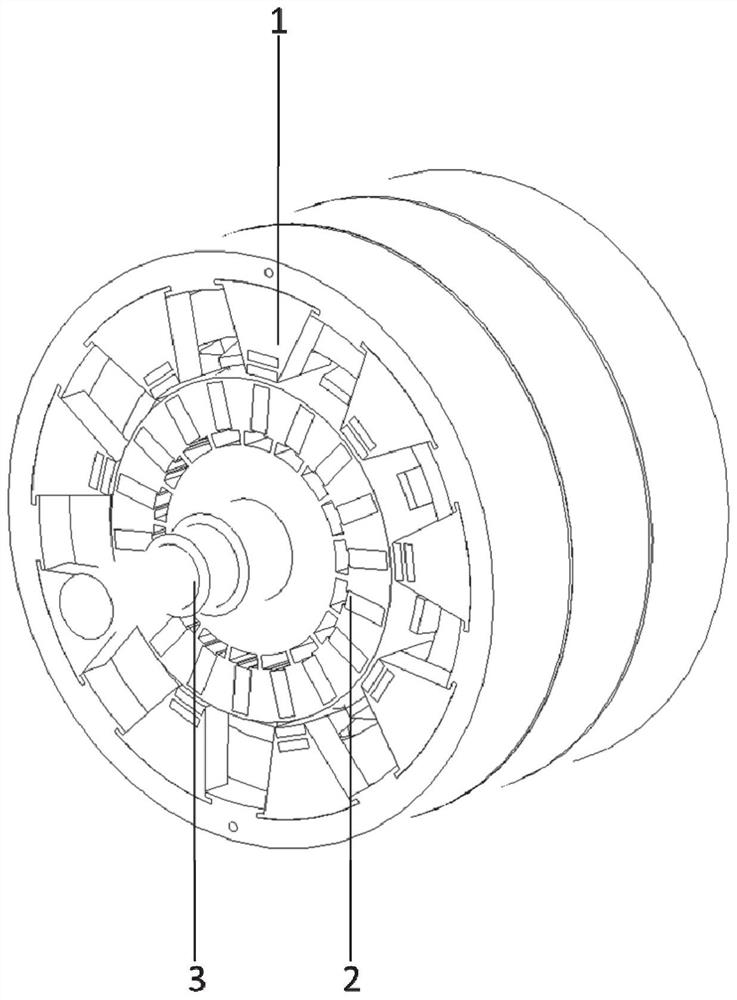

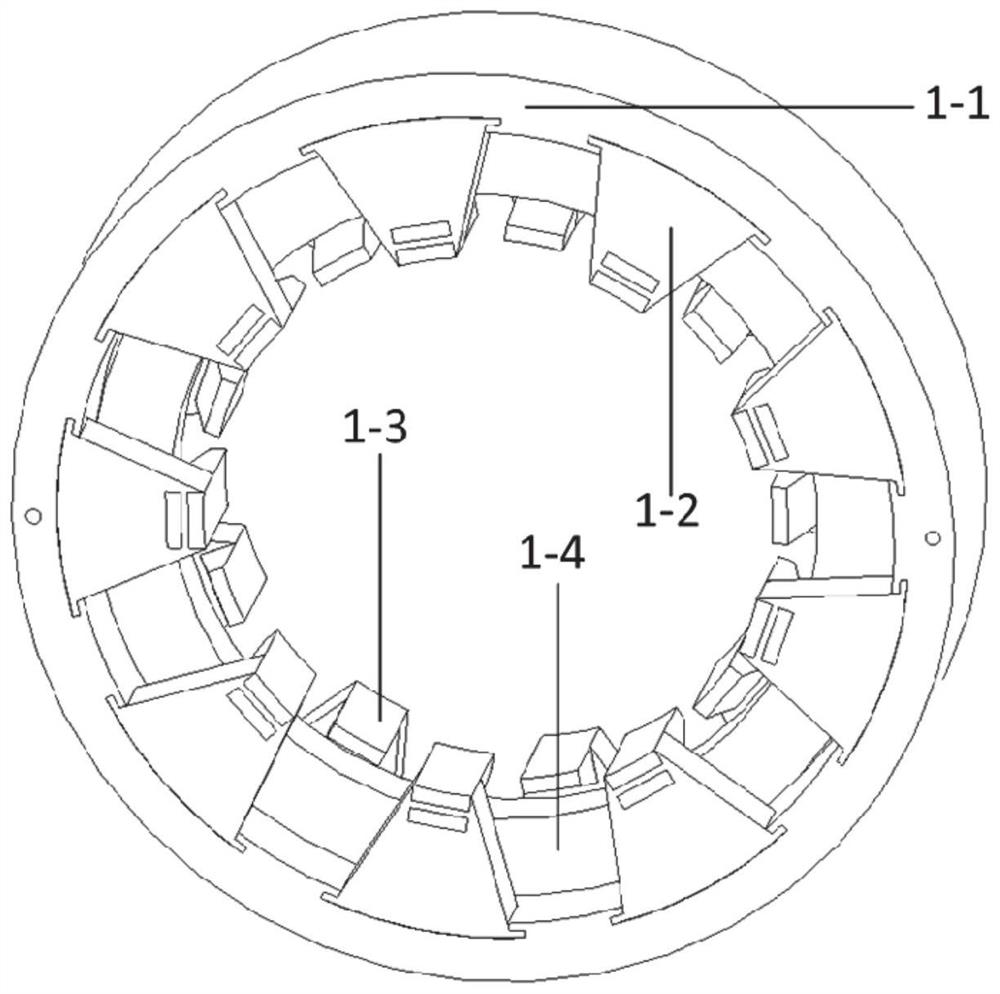

[0073] This embodiment discloses a combined stator core claw pole transverse magnetic flux permanent magnet brushless motor structure, such as figure 1 As shown, it includes a stator 1, a rotor 2 and a rotating shaft 3.

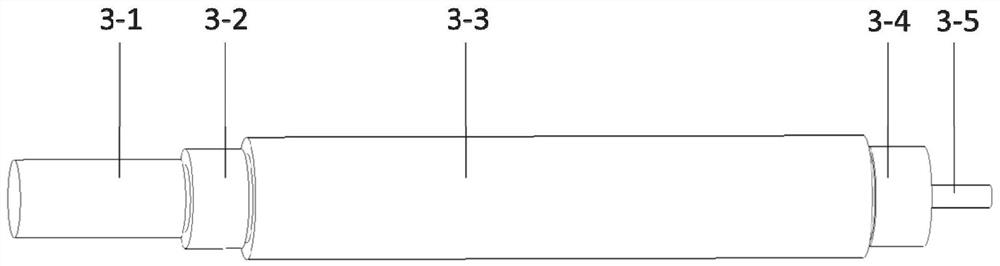

[0074] Rotary shaft 3 plays a key role in motor design and assembly, combined with figure 2 The rotating shaft segment is explained. The rotating shaft 3 includes the shaft extension end 3-1, the front bearing section 3-2, the rotor section 3-3, the rear bearing section 3-4, and the encoder section 3-5.

[0075] Specifically, the shaft extension end 3-1 of the rotating shaft 3 is used to output torque to connect the load; the front bearing section 3-2 is matched with the front bearing, and an interference fit is used during assembly; the rotor section 3-3 is matched with the rotor 2 to realize the torque The transmission from the motor to the rotating shaft; the rear bearing section 3-4 is matched with the rear bearing, and the assembly type adopts interfer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap