Livestock straw chopping and softening machine

A soft silk machine and soft silk technology, applied in the direction of harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of hard forage and incomplete soft silk of forage, and achieve the effect of stable operation of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

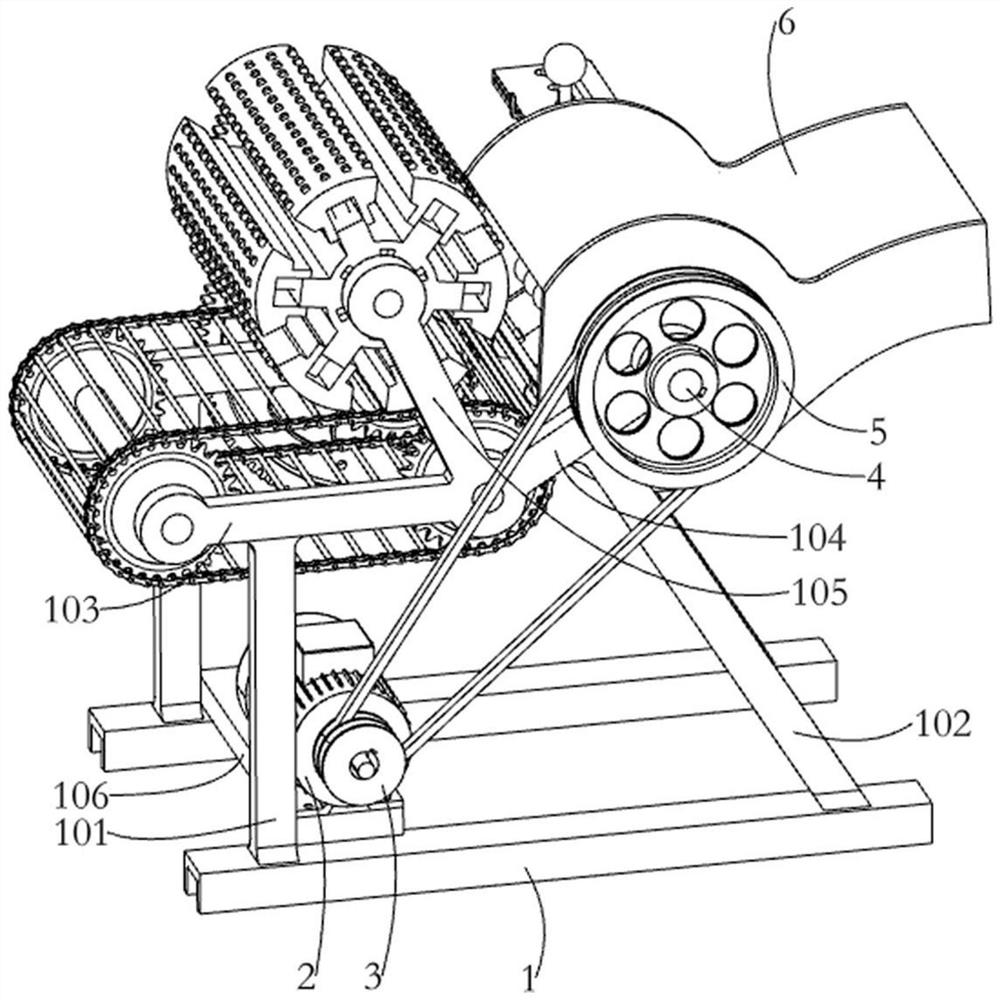

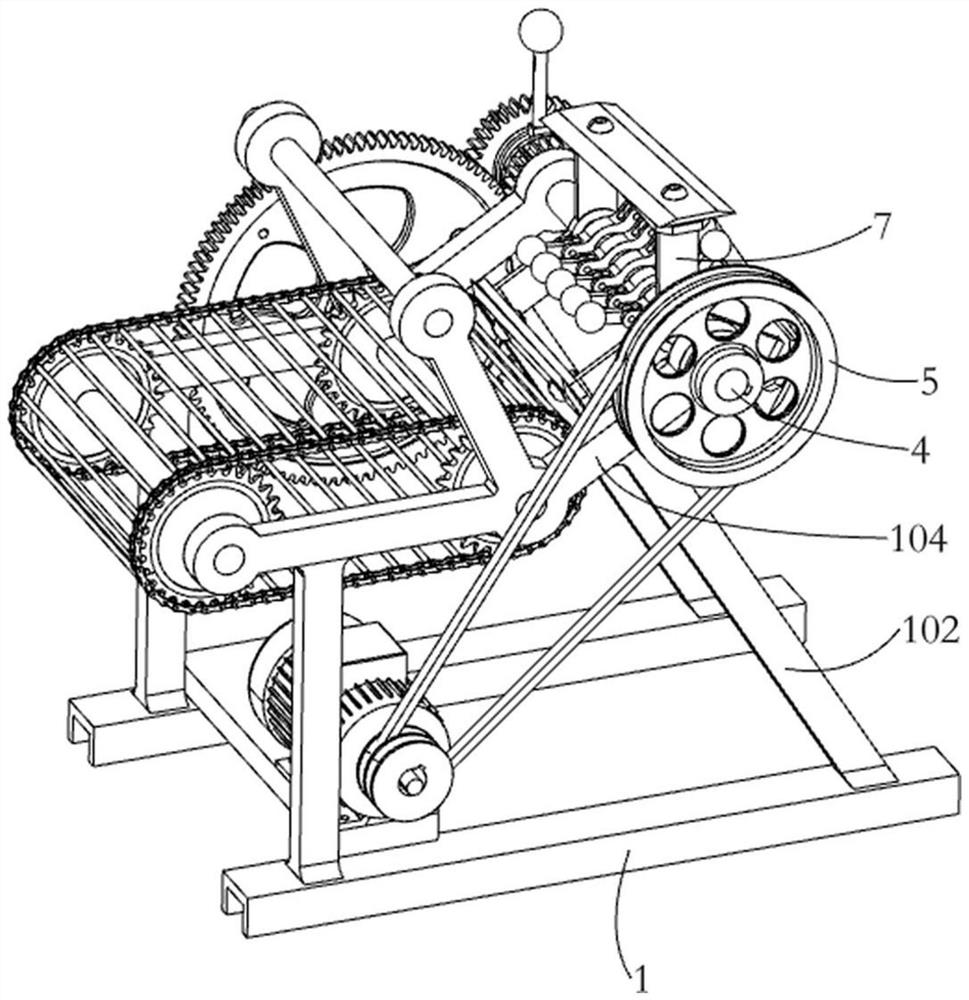

[0026] A kind of animal husbandry chopping grass softening machine, such as Figure 1-2 As shown, it includes a load-bearing frame 1, a first bracket 101, a second bracket 102, a third bracket 103, a fourth bracket 104, a fifth bracket 105, a load-bearing plate 106, a motor 2, a small pulley 3, and a first rotating shaft 4 , large pulley 5, shell 6, grass cutting mechanism and soft silk mechanism, bearing frame 1 is provided with two, both sides bearing frame 1 is symmetrical, and bearing frame 1 top is fixedly connected with first bracket 101 and second bracket 102, the second A third support 103 is fixedly connected above the first support 101, a fourth support 104 is connected above the second support 102, and a fifth support 105 is fixedly connected above the intersection of the third support 103 and the fourth support 104. A load-bearing plate 106 is fixedly connected to the side close to the first support 101 at the top, and a motor 2 is installed on the top of the load-...

Embodiment 2

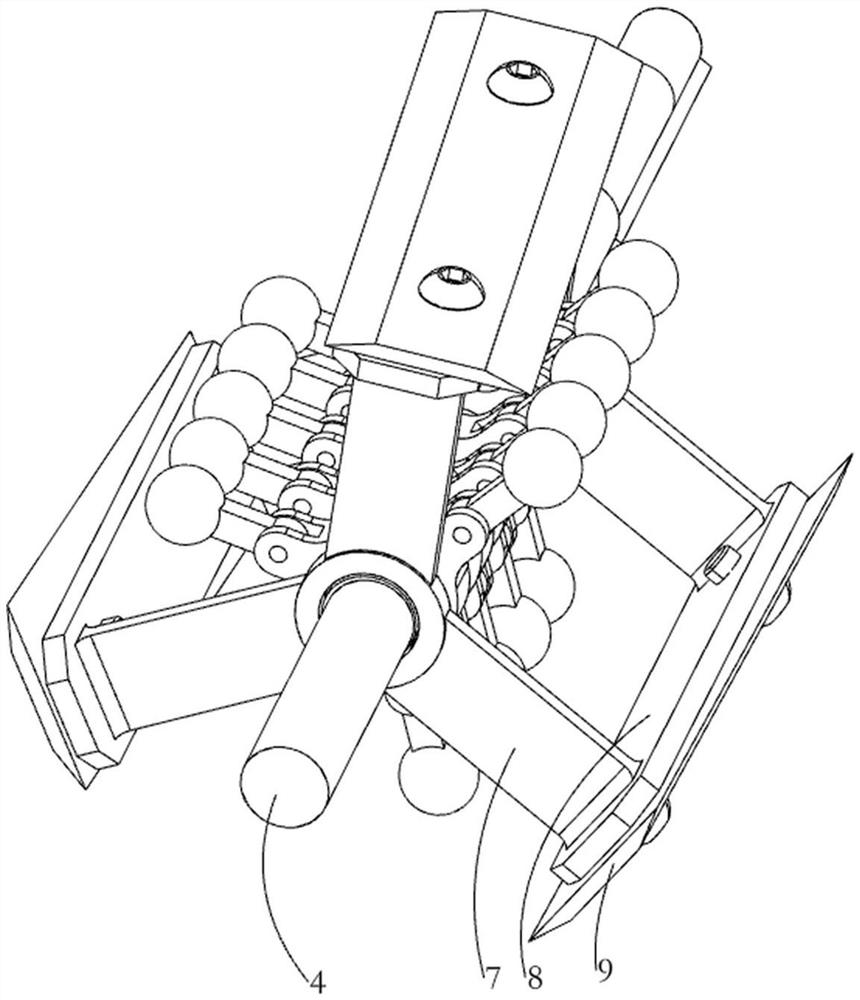

[0029] On the basis of Example 1, such as image 3 As shown, the grass cutting mechanism includes a triangular knife rest 7, a mounting plate 8 and a double-sided flat knife 9, two triangular knife rests 7 are fixedly connected to the first rotating shaft 4, and three mounting plates are connected to the brackets of the triangular knife rests 7 on both sides. 8. Double-sided flat knives 9 are installed on each mounting plate 8 through hexagon socket head bolts.

[0030] The first rotating shaft 4 drives the triangular knife rest 7 to rotate, and the double-sided flat knife 9 on the triangular knife rest 7 cuts the fodder entering the shell 6 into sections.

Embodiment 3

[0032] On the basis of Example 2, such as Figure 4 As shown, the flexible wire mechanism includes a triangular hammer frame 10, a swing lever 11 and a swing hammer head 12, and a plurality of triangular hammer frames 10 are fixedly connected to the first rotating shaft 4, and a plurality of triangular hammer frames 10 are located on both sides of the triangular knife. The inboard of frame 7, on the three angles of triangular hammer frame 10, all are hinged with a swing bar 11, and each swing bar 11 ends are all fixedly connected with swing tup 12.

[0033] The first rotating shaft 4 drives the triangular hammer frame 10 to rotate, and when the triangular hammer frame 10 rotates, the swing bar 11 and the swing tup 12 on it break the cut forage into a soft state.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap