Scalp anti-allergy nursing essence and preparation method thereof

A technology for essence and scalp, applied in skin care preparations, hair care, pharmaceutical formulations, etc., to repair the head skin, strengthen skin protection, and restore the protective barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

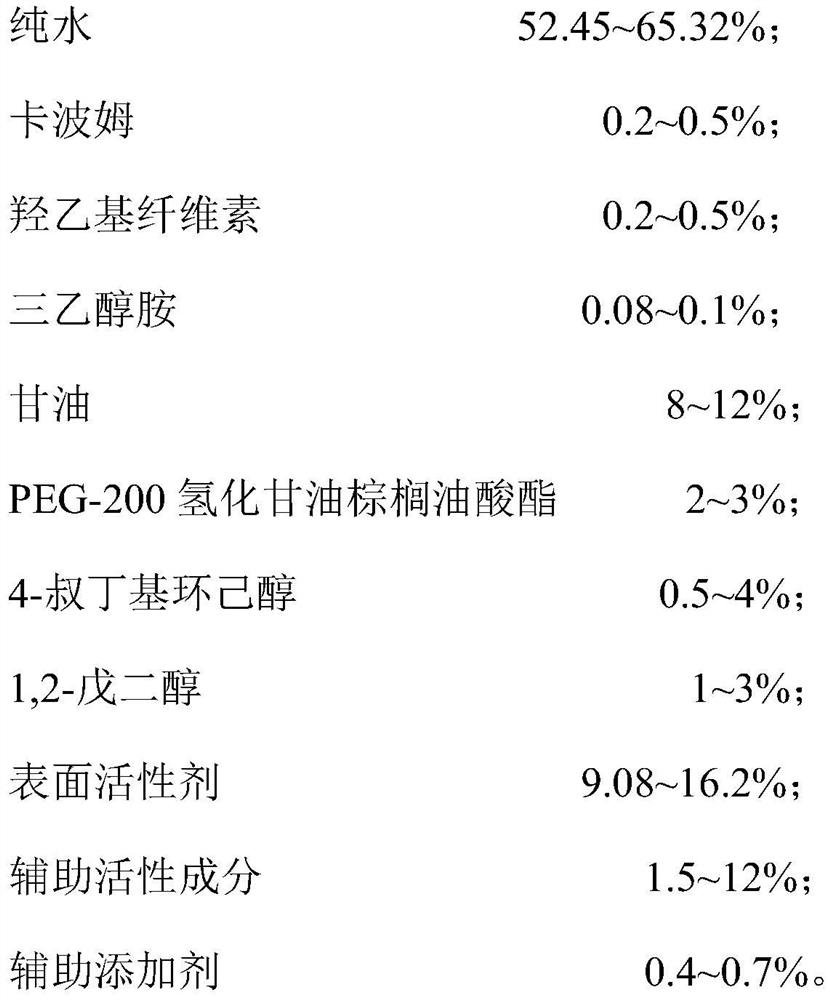

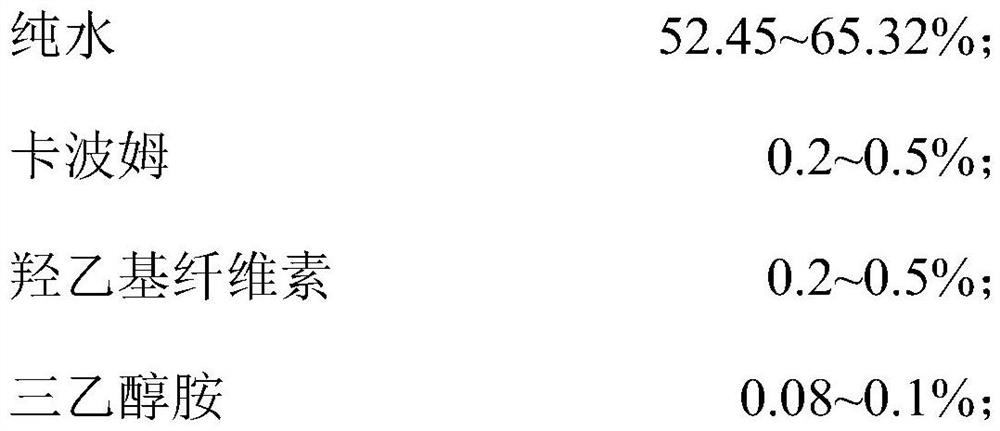

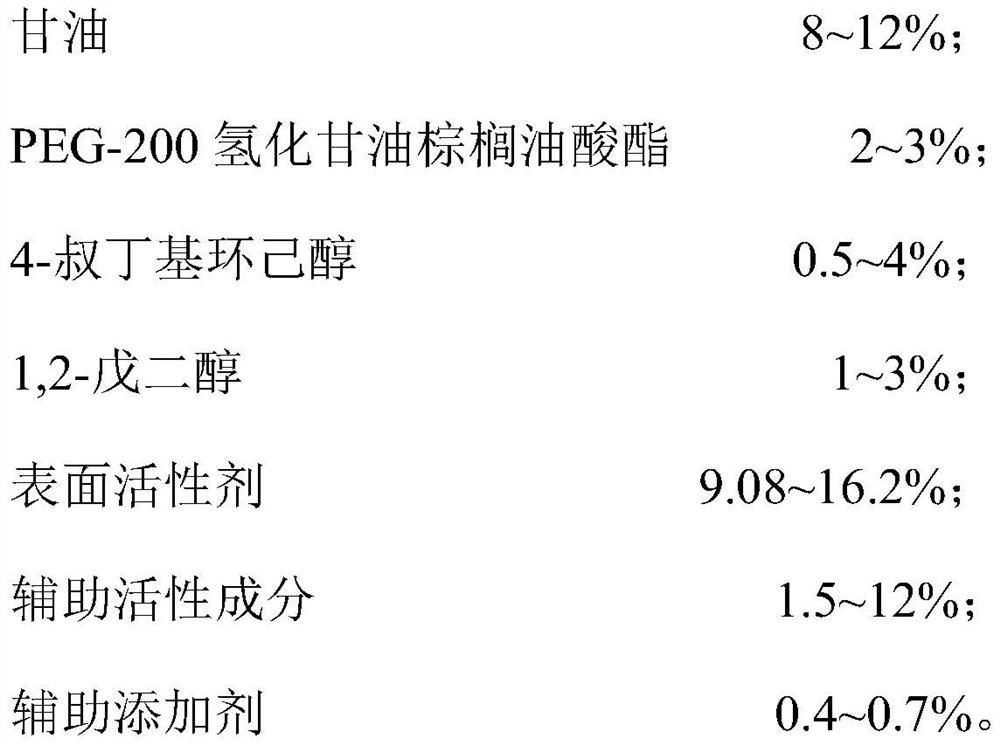

[0043] A scalp anti-allergic care essence, the components contained in it and the mass percentage of each component are shown in Table 1.

[0044] The preparation method of the above-mentioned scalp anti-allergic care essence comprises the following steps:

[0045] (1) Mix 60% pure water with carbomer, and control the rotating speed to be 650rpm and stir for 20min, homogenize 5 times during the stirring process, each time for 100s, to obtain pretreated carbomer;

[0046] (2) After heating 40% pure water to 90°C, add hydroxyethyl cellulose to the pure water, and control the rotation speed at 900rpm to stir for 15min, homogenize 4 times during the stirring process, each time for 100s, to obtain the pretreated hydroxyethyl cellulose Ethyl cellulose;

[0047] (3) Add the pretreated carbomer to the pretreated hydroxyethyl cellulose, and control the rotation speed to 700rpm and stir for 6 minutes, then add triethanolamine, and continue to stir for 6 minutes to obtain a mixture 1; ...

Embodiment 2

[0052] A scalp anti-allergic care essence, the components contained in it and the mass percentage of each component are shown in Table 1.

[0053] The preparation method of the above-mentioned scalp anti-allergic care essence comprises the following steps:

[0054] (1) Mix 60% pure water with carbomer, and control the rotating speed to be 550rpm and stir for 10min, homogenize 3 times during the stirring process, each time for 100s, to obtain pretreated carbomer;

[0055] (2) After heating 40% pure water to 80°C, add hydroxyethyl cellulose to the pure water, and control the rotation speed at 700rpm to stir for 10min, and homogenize twice during the stirring process, each time for 100s, to obtain the pretreated hydroxyethyl cellulose Ethyl cellulose;

[0056] (3) Add the pretreated carbomer to the pretreated hydroxyethyl cellulose, and control the rotation speed to 500 rpm to stir for 4 minutes, then add triethanolamine, and continue to stir for 4 minutes to obtain a mixture 1;...

Embodiment 3

[0061] A scalp anti-allergic care essence, the components contained in it and the mass percentage of each component are shown in Table 1.

[0062] The preparation method of the above-mentioned scalp anti-allergic care essence comprises the following steps:

[0063](1) Mix 60% pure water with carbomer, and control the rotating speed to be 600rpm and stir for 15min, homogenize 4 times during the stirring process, each time for 100s, to obtain pretreated carbomer;

[0064] (2) After heating 40% pure water to 85°C, add hydroxyethyl cellulose to the pure water, and control the rotation speed at 800rpm to stir for 12min, homogenize 3 times during the stirring process, each time for 100s, to obtain the pretreated hydroxyethyl cellulose Ethyl cellulose;

[0065] (3) Add the pretreated carbomer to the pretreated hydroxyethyl cellulose, and control the rotation speed to 600rpm and stir for 5 minutes, then add triethanolamine, and continue to stir for 5 minutes to obtain a mixture 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com