Antibacterial melt-blown material as well as preparation method and application thereof

A melt-blown, melt-blown polypropylene technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve cumbersome problems and achieve the effect of high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

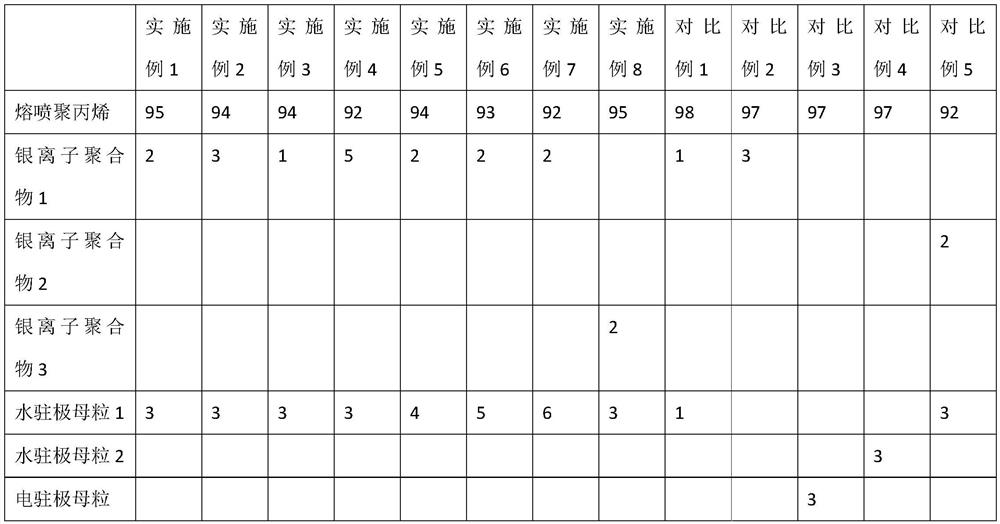

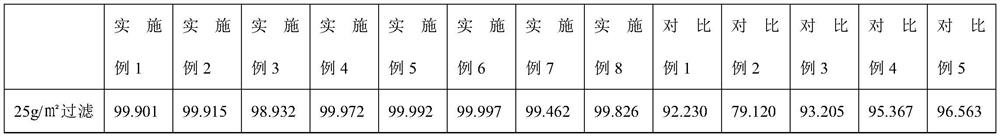

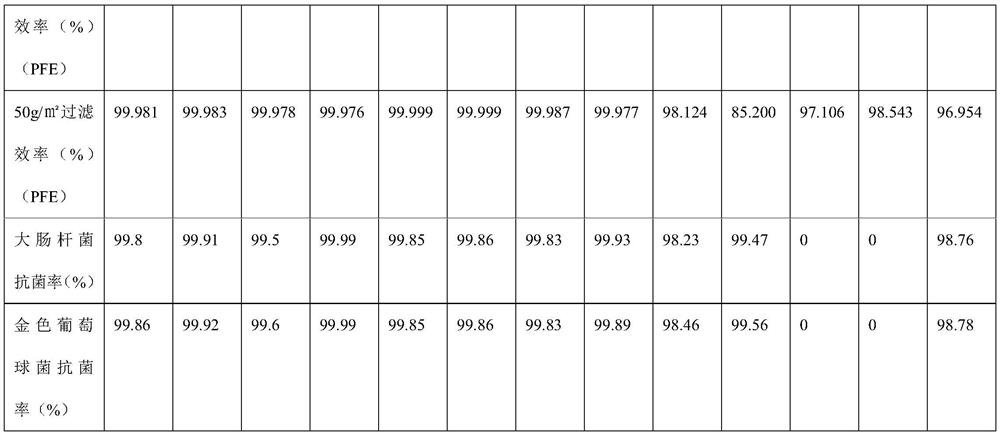

[0042]A antibacterial meltblown material comprising components calculated according to mass components as shown in Table 1 below.

[0043]The preparation method of the above antibacterial meltblown material includes the following steps:

[0044]The meltblown polypropylene resin, the aqueous residential particles, and the metal ion polymer were premixed, and the melt spray wire was performed on the meltblown machine, and the non-woven fabric was produced, and the non-woven fabric was subjected to water. It can be made to obtain an air filter meltblown fabric.

Embodiment 2~8 and comparative example 1~5

[0046]Example 2 to 8 and Components of Comparative Examples 1 to 5 and their mass parts are shown in Table 1 below, and their preparation methods are in Example 1.

[0047]Table 1 Component and its mass

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com