Manufacturing method and equipment for middle tube of badminton racket

A badminton racket and a production method technology, applied to other household appliances, household appliances, household components and other directions, can solve the problems of increasing the material of the middle tube, affecting the performance, increasing the production cost of the middle tube, etc., and improving the strength and impact resistance performance. , Improve the conductivity, improve the effect of forming pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

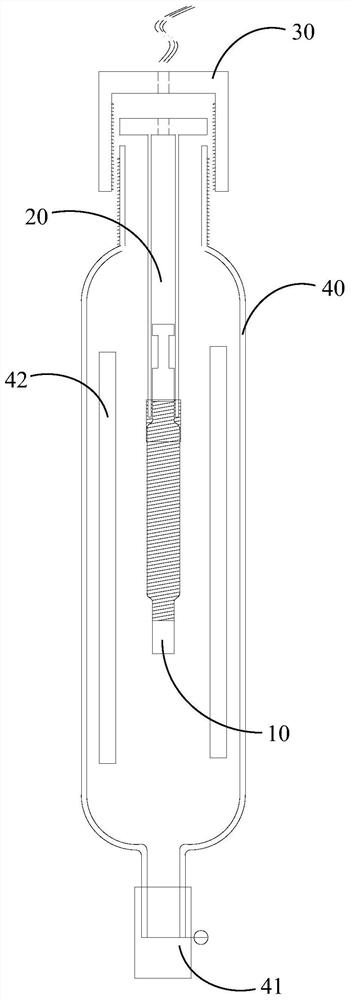

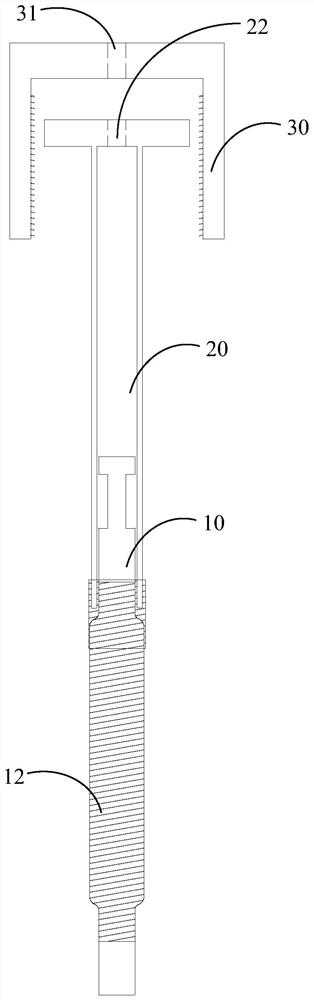

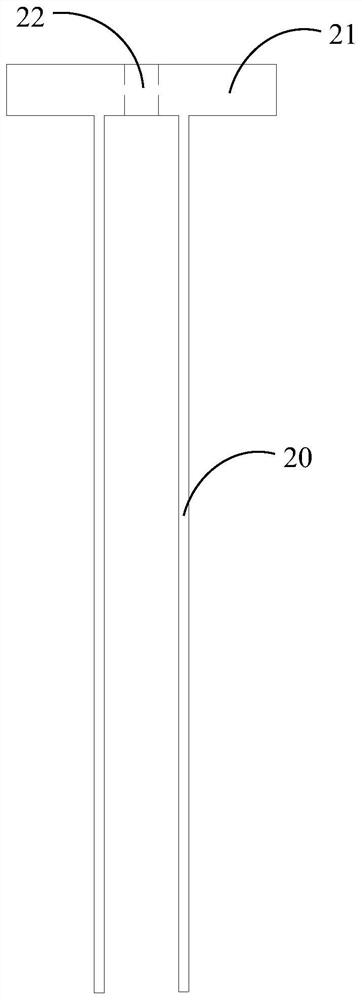

[0036] In order to better understand the purpose, structure and function of the present invention, the manufacturing method and manufacturing equipment of the badminton racket middle tube of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Such as Figure 1 to Figure 5 As shown, the manufacturing method of the badminton racket middle tube in the present invention comprises the following steps:

[0038] 1. Select the core material mold 10 according to the specification and size of the middle tube of the badminton racket to be made.

[0039] 2. Prepare carbon fiber cloth. According to the specification, size and performance design requirements of the middle tube to be produced, select the appropriate type and angle of carbon fiber cloth, and cut it into a suitable size.

[0040] 3. Smear release agent and carbon fiber cloth adhesive on the surface of core material mold 10, based on core material mold 10, ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com