System and method for diagnosing state of FOCKE packaging machine tobacco bale group input unit

An input unit and state diagnosis technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as long time consumption, difficult processing, and inconspicuous performance, achieve rapid and accurate diagnosis, solve maintenance problems, and improve maintenance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

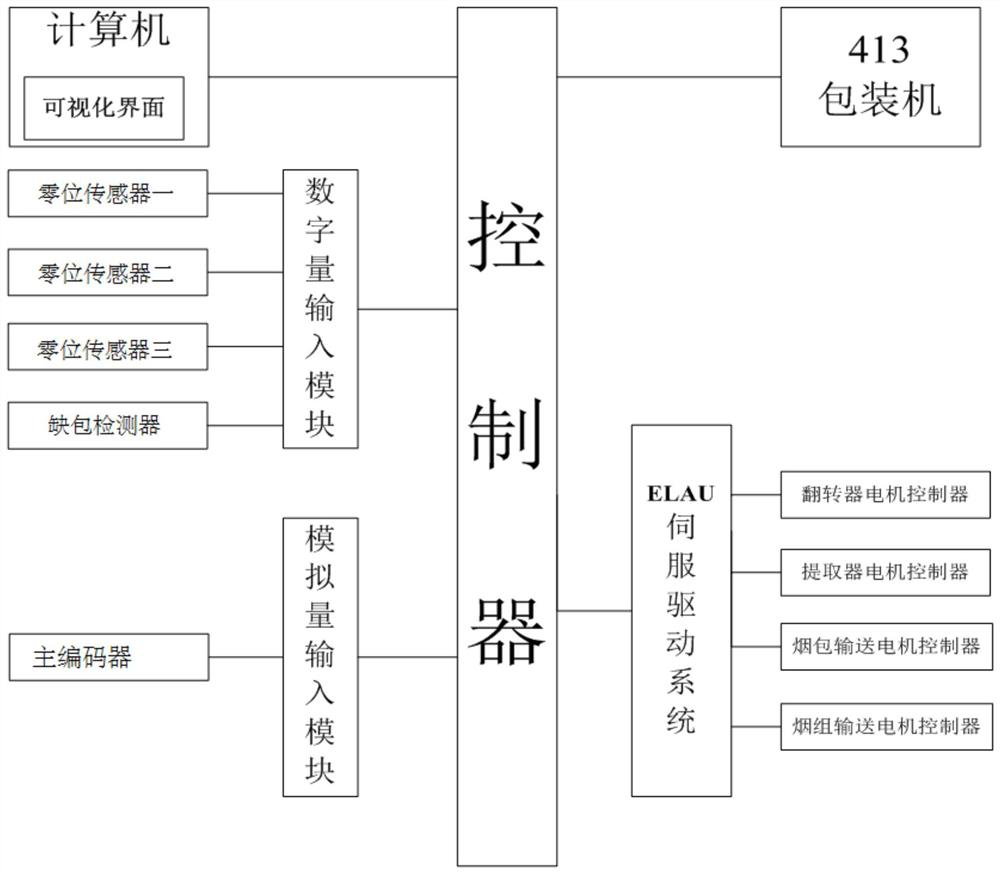

[0029] Such as Figure 1 to Figure 4 As shown, a FOCKE packaging machine cigarette packet group input unit status diagnosis system includes PLC controller, computer, digital input module, analog input module, ELAU servo drive system, zero sensor one, zero sensor two and zero position sensor three;

[0030] Described PLC controller is respectively connected with computer, digital quantity input module, analog quantity input module, ELAU servo drive system and 413 packaging machines;

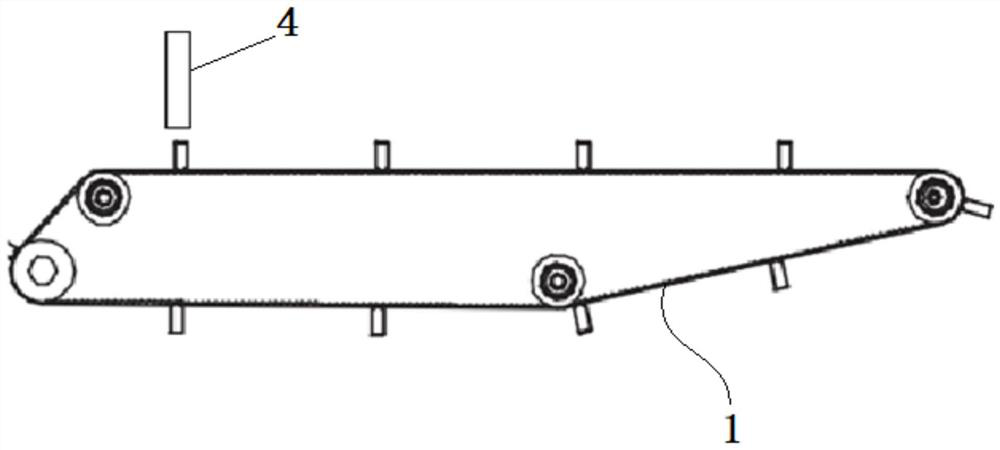

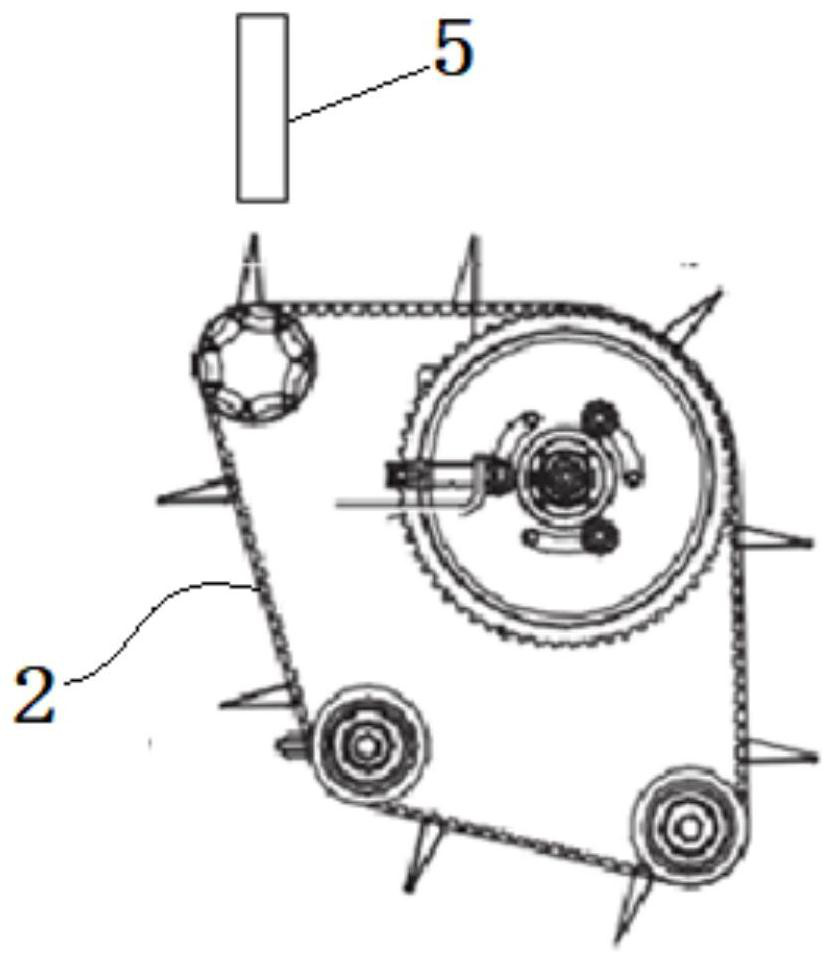

[0031] The zero position sensor one is fixedly installed on the side above the cigarette group conveyor belt, and a plurality of metal blocks one matched with the zero position sensor one are evenly installed on the cigarette group conveyor belt, and the zero position sensor one is used for detecting When any metal block runs directly below, send a zero electric signal to the digital input mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com