Waterborne epoxy wet-on-wet polyurethane matched paint applied to engineering machinery and preparation method of waterborne epoxy wet-on-wet polyurethane matched paint

A construction machinery, epoxy wet technology, applied in polyurea/polyurethane coatings, epoxy resin coatings, primers, etc., can solve the problems of decreased adhesion between layers, poor compatibility of topcoats, and primer bites, etc., to achieve improved Production efficiency and the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

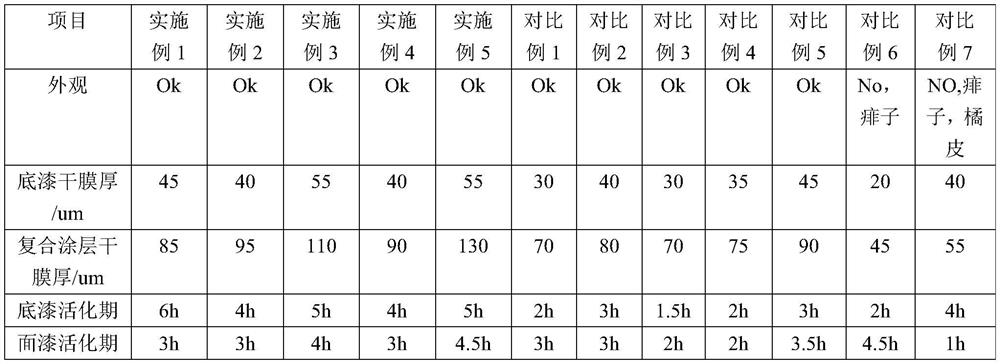

Embodiment 1

[0060] An embodiment of the present invention provides a water-based epoxy "wet-on-wet" polyurethane matching paint applied to engineering machinery, including a two-component water-based epoxy antirust primer and a two-component water-based hydroxypropyl paint.

[0061] Described water-based two-component epoxy anticorrosion primer is divided into A, B two-component, and each raw material mass percent of A component is: water-based epoxy resin 42.5%, deionized water 12%, the first dispersant 2.30%, pH Regulator 0.10%, pigments and fillers 30%, zinc phosphate 5%, ZMP5%, carbon black 0.20%, first wetting and leveling agent 0.15%, first thickener 0.20%, second thickener 0.10%, second 0.15% defoamer, 0.30% anti-flash rust additive, 2.00% first film-forming additive;

[0062] Each raw material mass percent of described water-based two-component epoxy anticorrosion primer B component is: water-based epoxy curing agent 50%, deionized water 30% and the second film-forming aid 20%;

...

Embodiment 2

[0079] An embodiment of the present invention provides a water-based epoxy "wet-on-wet" polyurethane matching paint applied to engineering machinery, including a two-component water-based epoxy antirust primer and a two-component water-based hydroxypropyl paint.

[0080] Described water-based two-component epoxy anticorrosion primer is divided into A, B two-component, and each raw material mass percent of A component is: water-based epoxy resin 60%, deionized water 10%, the first dispersant 1.80%, pH Conditioner 0.15%, pigments and fillers 20%, zinc phosphate 3%, ZMP3%, carbon black 0.10%, first wetting and leveling agent 0.15%, first thickener 0.25%, second thickener 0.10%, second 0.15% defoamer, 0.30% anti-flash rust additive, 1.00% first coalescence additive;

[0081] Each raw material mass percentage of described water-based two-component epoxy anticorrosion primer B component is: water-based epoxy curing agent 60%, deionized water 10% and the second film-forming aid 30%;

...

Embodiment 3

[0098] An embodiment of the present invention provides a water-based epoxy "wet-on-wet" polyurethane matching paint applied to engineering machinery, including a two-component water-based epoxy antirust primer and a two-component water-based hydroxypropyl paint.

[0099] Described water-based two-component epoxy anticorrosion primer is divided into A, B two-component, and each raw material mass percent of A component is: water-based epoxy resin 50%, deionized water 13%, the first dispersant 2.20%, pH Regulator 0.10%, pigments and fillers 25%, zinc phosphate 3%, ZMP4%, carbon black 0.20%, first wetting and leveling agent 0.20%, first thickener 0.25%, second thickener 0.10%, second 0.15% defoamer, 0.30% anti-flash rust additive, 1.50% first coalescence additive;

[0100] Each raw material mass percentage of described water-based two-component epoxy anticorrosion primer B component is: water-based epoxy curing agent 60%, deionized water 20% and the second film-forming aid 20%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com