Automobile sealant, preparation method and use method thereof

A sealant, automotive technology, applied in the directions of adhesives, coatings, adhesive additives, etc., can solve the problems of affecting the appearance performance of the car body, long time for car body production, low production efficiency, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] As an implementation manner of the embodiment of the present invention, the raw material of the sealant further includes 2-5 parts by weight of additives. Additives are used to adjust the finished state of automotive sealants and to assist other components in film formation. The auxiliary agent may include at least one of a thixotropic agent and a tackifier, wherein the thixotropic agent may be fumed silica, and the tackifier may be polyamide resin.

[0056] In the second aspect, the embodiment of the present invention provides the above-mentioned method for preparing an automobile sealant, wherein the method comprises:

[0057] The automobile sealant is prepared by mixing the raw materials of the automobile sealant, and the raw material of the automobile sealant includes the following components in parts by weight: benzene disulfonate: 14-18 parts; diisononyl phthalate: 12-16 parts; isoparaffin solvent: 2.5-3.5 parts; filler: 19-21 parts; PVC resin: 42-45 parts.

[0...

Embodiment 1

[0070] Embodiment 1 provides an automobile sealant and its application method. The raw materials of the sealant are composed of the components shown in Table 1.

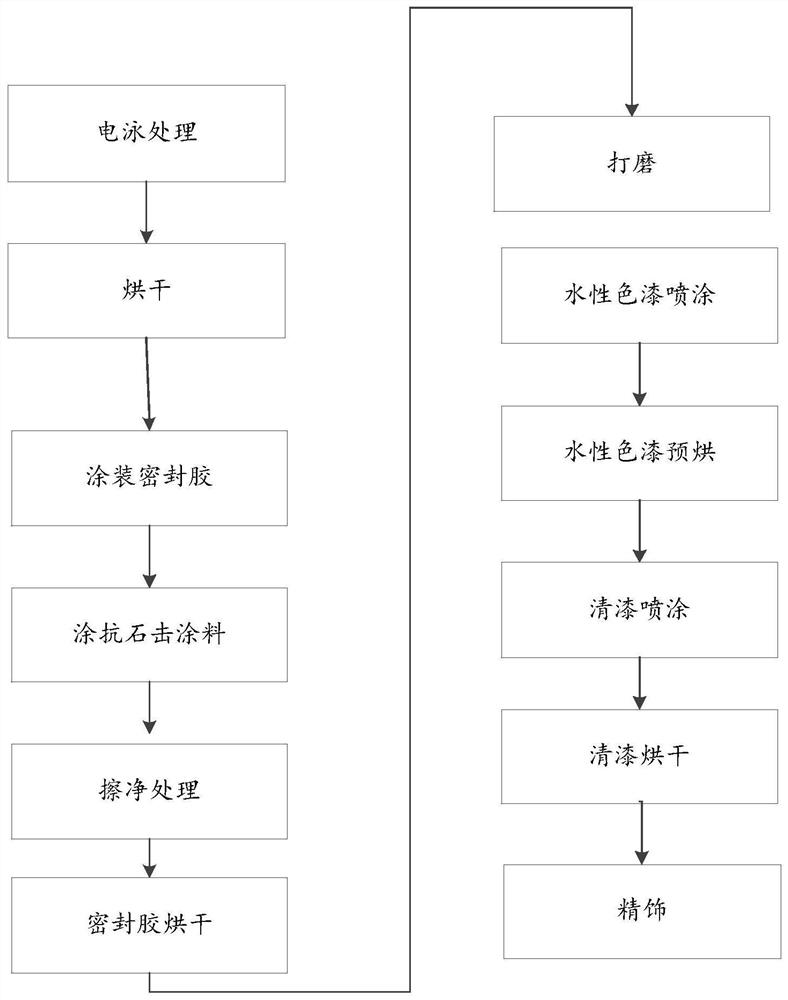

[0071] How to use automotive sealant, combined with figure 2 ,details as follows:

[0072] (1) On the painting production line of a certain vehicle factory, the body-in-white to be sprayed is dried after electrophoresis treatment, and then the body is polished, cleaned and repainted;

[0073] (2) Apply sealant to the welded seam of the car door and the welded seam of the bottom of the car after the above-mentioned process, and then apply the anti-stone chip coating; 5mm*3mm, 10mm*5mm, 10mm*1mm

[0074] (3) Wipe the body after the above process, and use alcohol to wipe the residual glue, glue traces, offset printing, oil stains, etc. on the outer surface;

[0075] (4) The body after the (3) process is transported to the spray booth for water-based color paint spraying. Color paint BC1 and BC2 are sprayed by robot...

Embodiment 2

[0080] Embodiment 2 provides an automobile sealant and its application method. The raw materials of the sealant consist of the components shown in Table 1.

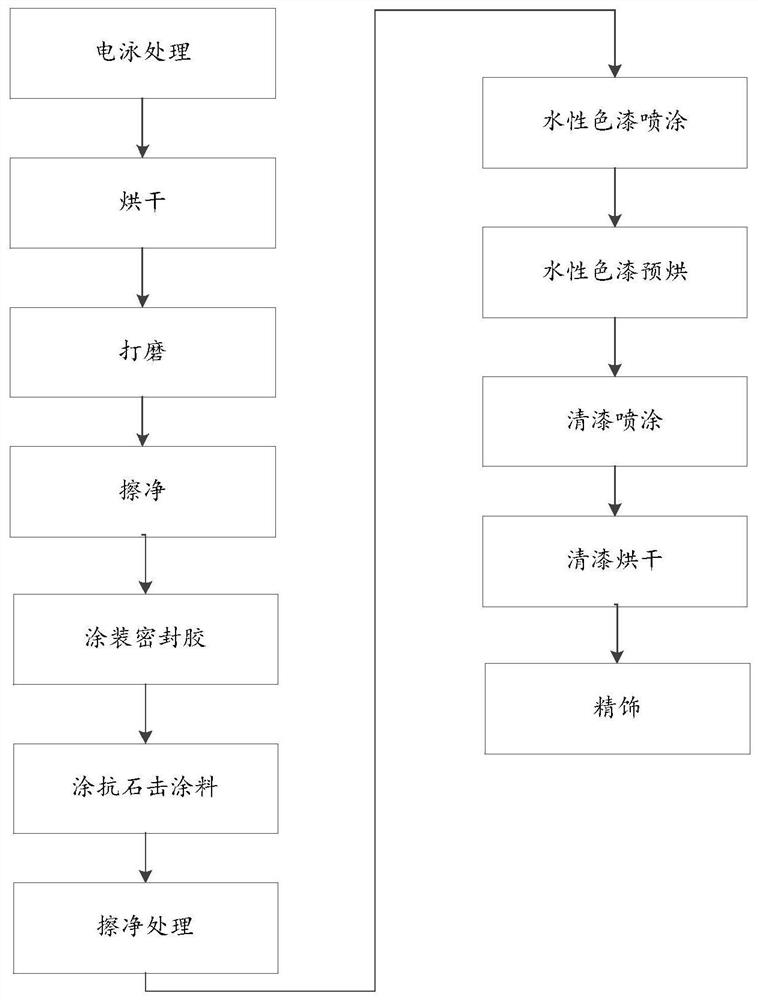

[0081] How to use automotive sealant, combined with image 3 ,details as follows:

[0082] On the painting production line of a certain vehicle factory, the body-in-white to be painted is dried after electrophoresis treatment, and then the body is polished, cleaned and repainted;

[0083] (2) Apply sealant to the welded seam of the car door and the welded seam of the bottom of the car after the above-mentioned process, and then apply the anti-stone chip coating; 5mm*3mm, 10mm*5mm, 10mm*1mm

[0084] (3) Wipe the body after the above process, and use alcohol to wipe the residual glue, glue traces, offset printing, oil stains, etc. on the outer surface;

[0085] (4) The body after the (3) process is transported to the spray booth for water-based color paint spraying. Color paint BC1 and BC2 are sprayed by robots on the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com