Demulsifier, demulsifier composition, preparation method of demulsifier, and application of demulsifier and demulsifier composition

A technology of demulsifier and composition, which is applied in the field of oil field chemicals, can solve the problems of environmental pollution and high cost of demulsifier, and achieve the effect of reducing the interfacial tension of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] This specific embodiment proposes a method for preparing a demulsifier, comprising the steps of: mixing rice husk and sulfuric acid with a concentration of 0.5-1 mol / L in a polytetrafluoroethylene reactor lining at a mass ratio of 1:15-40, and Carry out hydrothermal reaction at 160-200°C for 8-16 hours, then wash the rice husk after hydrothermal reaction to neutrality, and then vacuum freeze-dry at -52-40°C for 1-4 days to obtain the demulsifier .

[0022] This specific embodiment also includes the demulsifier prepared by the above preparation method.

[0023] This specific embodiment also proposes a demulsifier composition, comprising the above demulsifier and sodium chloride; further, the mass ratio of the demulsifier to the sodium chloride is 1:50-100.

[0024] This specific embodiment also includes the application of the above-mentioned demulsifier or demulsifier composition in the treatment of W / O crude oil emulsion.

Embodiment 1

[0027] Present embodiment proposes a kind of demulsifier, is made by following steps:

[0028] In parts by weight, first weigh 2 parts of rice husks in the lining of a polytetrafluoroethylene reactor, and then measure 35 parts of prepared 1mol / L H 2 SO 4 The solution was placed in the lining of a polytetrafluoroethylene reactor, and reacted hydrothermally at 180°C for 12 hours. After the reaction, it was naturally cooled to room temperature, washed repeatedly with distilled water until neutral, and then the product was vacuum freeze-dried. The vacuum freeze-drying temperature was -50°C, drying time is 1 day to obtain the demulsifier.

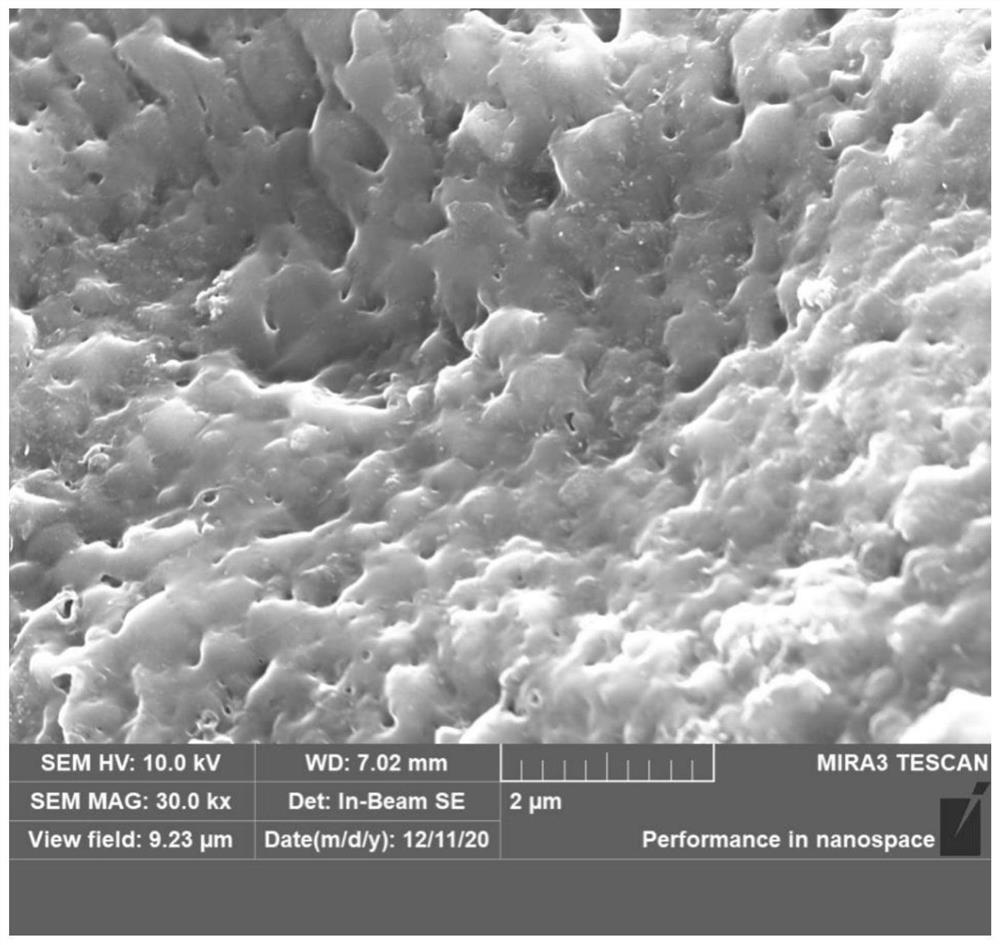

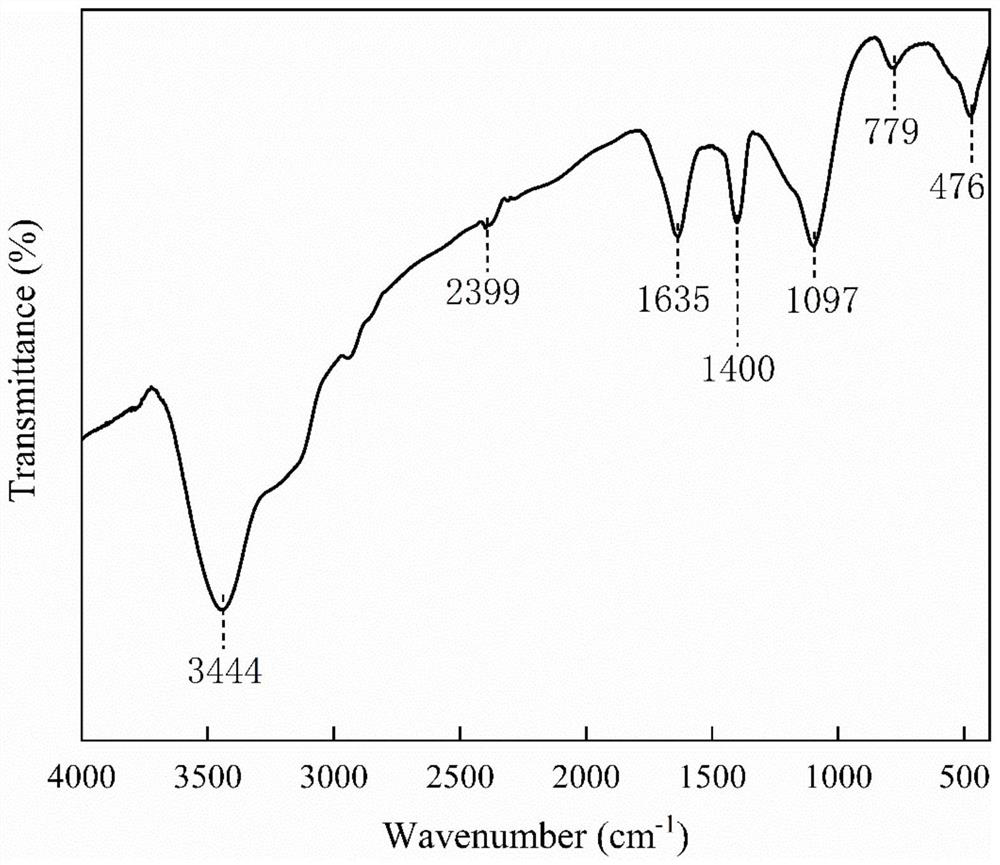

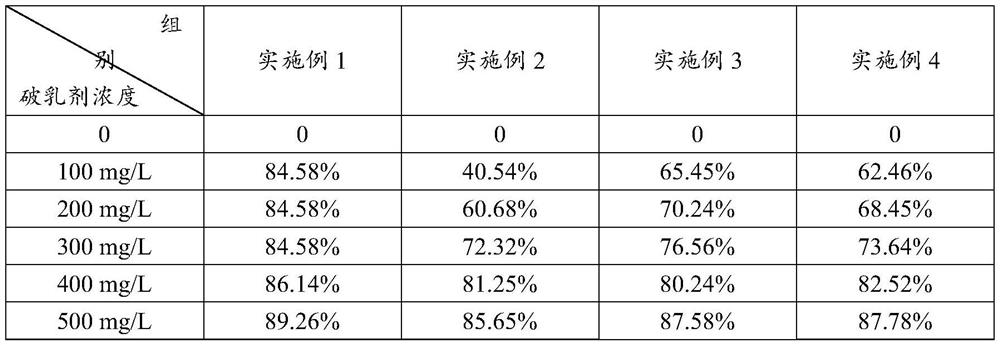

[0029] The obtained demulsifier of embodiment 1 is characterized, figure 1 It is the SEM figure of embodiment 1 gained demulsifier, by figure 1 It can be seen that the rice husk after the reaction presents a porous structure; figure 2 It is the FT-IR figure of embodiment 1 gained waste rice husk demulsifier, by figure 2 It can be seen tha...

Embodiment 2

[0031] Present embodiment proposes a kind of demulsifier, is made by following steps:

[0032] In parts by weight, first weigh 2 parts of rice husks in the lining of a polytetrafluoroethylene reactor, and then measure 40 parts of prepared 0.5mol / L H 2 SO 4 The solution was placed in the lining of a polytetrafluoroethylene reactor, and reacted hydrothermally at 160°C for 16 hours. After the reaction, it was naturally cooled to room temperature, washed repeatedly with distilled water until neutral, and then the product was subjected to vacuum freeze-drying. The vacuum freeze-drying temperature was -40°C, drying time is 4 days to obtain a demulsifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com