A method and device for strengthening aluminum alloy components by electromagnetic force at room temperature cycle

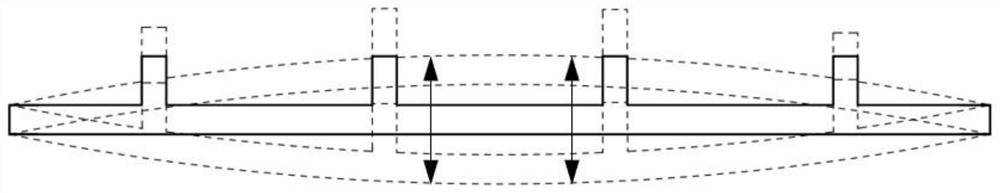

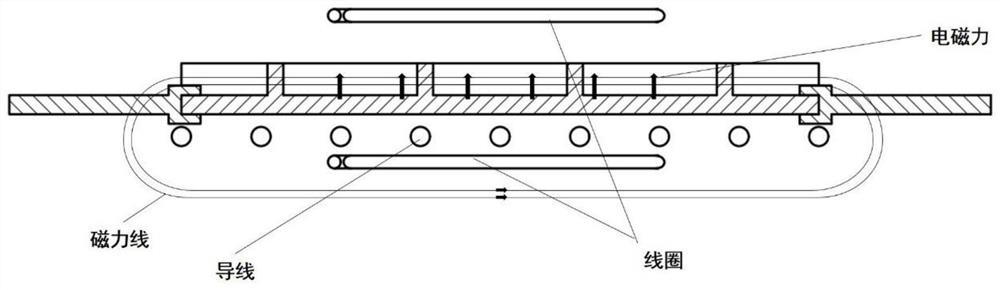

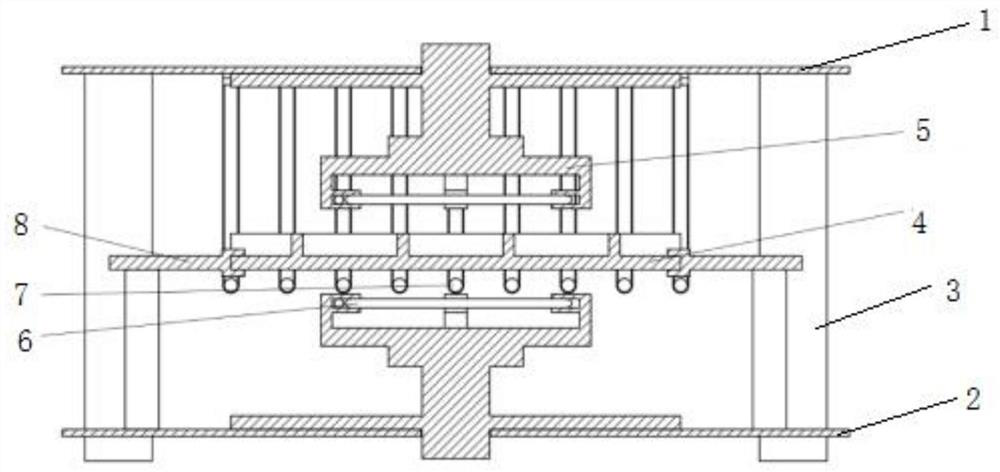

An aluminum alloy component and electromagnetic force technology, which is applied in the field of electromagnetic force room temperature cyclic strengthening of aluminum alloy components, can solve the problems that limit the industrial application of high-performance aluminum alloy components, the performance of the core of components cannot meet the requirements of use, the yield of aluminum alloy components and the Quality reduction and other problems, to achieve the effect of improving forming accuracy and manufacturing efficiency, excellent strengthening effect, and reducing strengthening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The 2024 aluminum alloy was solution-treated at 493 °C for 1 h in an air circulation resistance furnace, and after water quenching, an aluminum alloy plate was obtained. The electromagnetic force cycle strengthening was carried out at room temperature of 25 ℃, the cycle frequency was 0.2Hz, the cycle number was 450 times, the cycle electromagnetic force amplitude was 290MPa, and the stress ratio was R=-1. After the cyclic strengthening, fatigue test and tensile test were carried out respectively.

Embodiment 2

[0046] The 6061 aluminum alloy was solution-treated at 530°C for 1 h in an air circulation resistance furnace, and then quenched in water to obtain an aluminum alloy plate. The electromagnetic force cycle strengthening was carried out at room temperature of 25℃, the cycle frequency was 0.02Hz, the cycle number was 700 times, the cycle electromagnetic force amplitude was 226MPa, and the stress ratio was R=-1. After the cyclic strengthening, fatigue test and tensile test were carried out respectively.

Embodiment 3

[0048] The 7050 aluminum alloy was solution-treated at 480°C for 1 h in an air circulation resistance furnace, and then quenched in water to obtain an aluminum alloy plate. The electromagnetic force cycle strengthening was carried out at room temperature of 25°C, the cycle frequency was 0.2Hz, the cycle number was 700 times, the cycle electromagnetic force amplitude was 300MPa, and the stress ratio was R=-1. After the cyclic strengthening, fatigue test and tensile test were carried out respectively.

[0049] The mechanical property data of the aluminum alloy components obtained in the examples and comparative examples are specifically shown in Table 1.

[0050] Table 1 Mechanical properties data of aluminum alloy components

[0051]

[0052]

[0053] It can be seen from Table 1 that using the method proposed in the present invention can effectively improve the fatigue strength of aluminum alloy components at room temperature, and can obtain larger yield strength and ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com