Method for preparing cushion packaging material from bamboo fibers

A cushioning packaging and bamboo fiber technology, which is applied in fiber raw material processing, packaging, wrapping paper, etc., can solve the problems of complex extraction of bamboo leach liquid, achieve good flame-retardant and waterproof effects, low apparent density, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

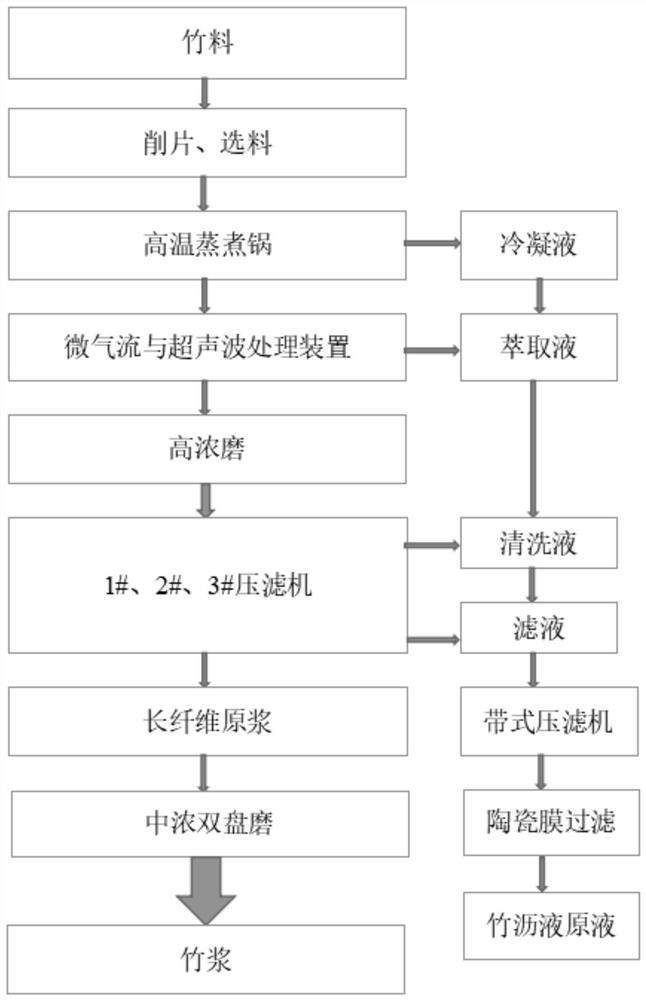

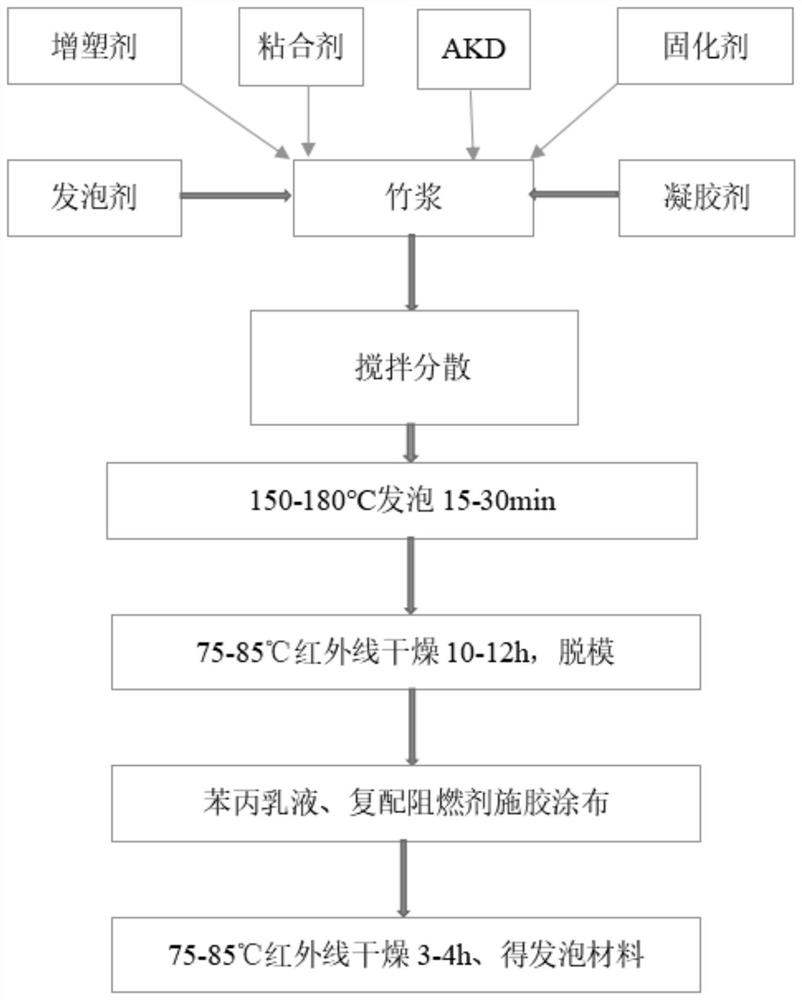

[0031] The purpose of this embodiment is to provide a kind of method utilizing bamboo fiber to prepare cushioning packaging material, comprising the following steps:

[0032] (1) chipping screening: the bamboo is chipped by a chipper, and the bamboo chips with a length of 8-60 mm and a thickness of 2-20 mm are screened;

[0033] (2) Steaming: Put the screened bamboo slices into a cooking pot, feed high-temperature steam to raise the temperature to 160°C, and keep warm for 18 minutes;

[0034] (3) Micro-air flow and ultrasonic treatment: the softened bamboo chips are taken out, and the condensate is collected simultaneously. After softening, the bamboo chips are put into the micro-air flow and ultrasonic treatment for extraction while hot, and the bamboo liquid is extracted into the water, and the bamboo fibers are dispersed simultaneously;

[0035] (4) High-consistency refining: put the ultrasonically treated bamboo fiber into a high-consistency mill for beating, further extru...

Embodiment 2

[0048] The purpose of this embodiment is to provide a kind of method utilizing bamboo fiber to prepare cushioning packaging material, comprising the following steps:

[0049] (1) chipping screening: the bamboo is chipped by a chipper, and the bamboo chips with a length of 8-60 mm and a thickness of 2-20 mm are screened;

[0050] (2) Steaming: Put the screened bamboo slices into a cooking pot, feed high-temperature steam to raise the temperature to 170°C, and keep warm for 15 minutes;

[0051] (3) Micro-air flow and ultrasonic treatment: the softened bamboo chips are taken out, and the condensate is collected simultaneously. After softening, the bamboo chips are put into the micro-air flow and ultrasonic treatment for extraction while hot, and the bamboo liquid is extracted into the water, and the bamboo fibers are dispersed simultaneously;

[0052] (4) High-consistency refining: Put the ultrasonically treated bamboo fiber into a high-consistency mill for beating, further extru...

Embodiment 3

[0065] The purpose of this embodiment is to provide a kind of method utilizing bamboo fiber to prepare cushioning packaging material, comprising the following steps:

[0066] (1) chipping screening: the bamboo is chipped by a chipper, and the bamboo chips with a length of 8-60 mm and a thickness of 2-20 mm are screened;

[0067] (2) Steaming: Put the screened bamboo slices into a cooking pot, feed high-temperature steam to raise the temperature to 165°C, and keep warm for 25 minutes;

[0068] (3) Micro-air flow and ultrasonic treatment: the softened bamboo chips are taken out, and the condensate is collected simultaneously. After softening, the bamboo chips are put into the micro-air flow and ultrasonic treatment for extraction while hot, and the bamboo liquid is extracted into the water, and the bamboo fibers are dispersed simultaneously;

[0069] (4) high-consistency refining: the bamboo fibers treated by ultrasonic waves are put into a high-consistency mill for beating, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com