Rod transporting vehicle device suitable for vertical shaft drilling and using method

A technology for drilling and transporting rods, applied in the directions of drilling rods, transportation and packaging, drilling pipes, etc., can solve the problems of time-consuming and laborious manual dragging, construction obstacles, and self-heavy drilling rods, so as to facilitate the handling and installation work, simplify the Easy to install and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

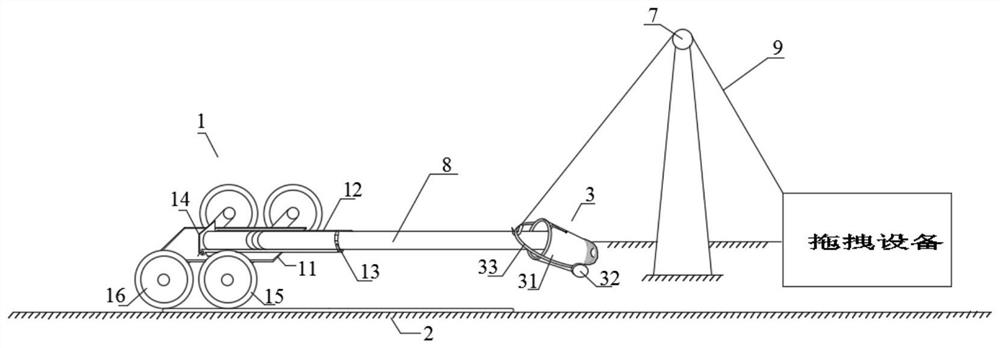

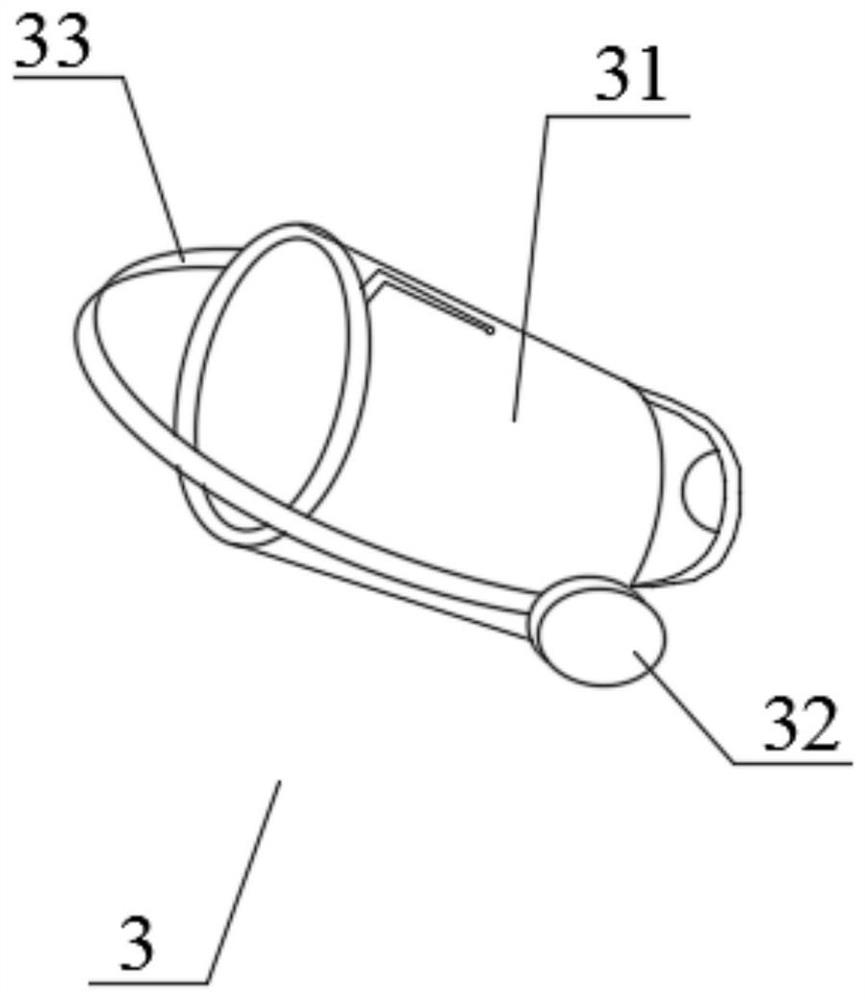

[0039] During the construction of a shaft, a drill pipe with a length of 9.6m, a diameter of 16.5cm and a weight of 168kg was used. Because the drill pipe was too heavy, the installation of the drill pipe was difficult, so the above-mentioned rod truck device was used to assist in the installation.

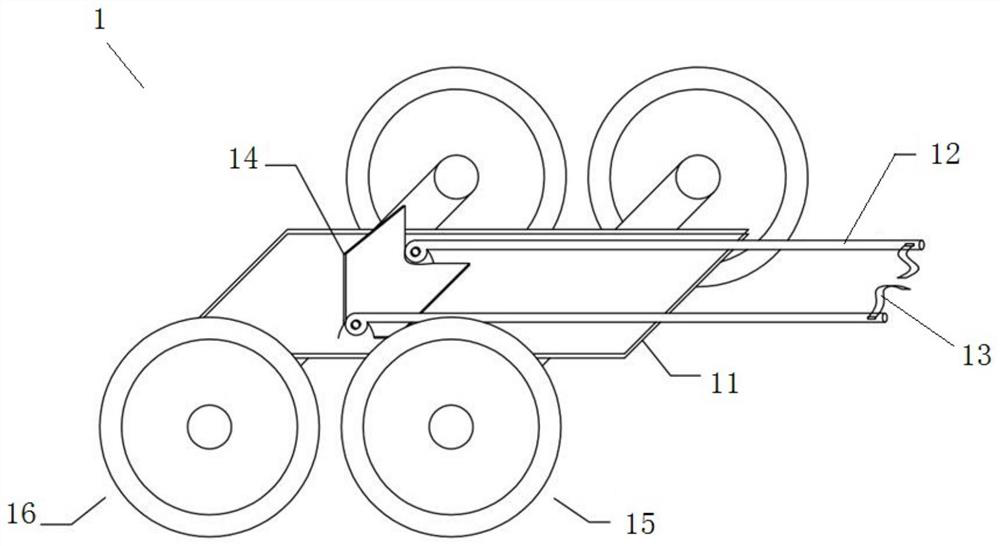

[0040] The wheel inner circle diameter of the four-wheel carrier vehicle 1 of transport bar car device is 20cm, and the outer circle diameter is 25cm. The 15 wheel spacings of the front wheels of the carrier are 80cm, and the 16 wheel spacings of the rear wheels of the carrier are 80cm.

[0041] Bearing plate 11 is a rectangular plate with a length of 70cm, a width of 30cm, and a thickness of 1.5cm; the two ends of bearing plate 11 are 1625cm away from the front wheel 15 of the carrier and the rear wheel of the carrier. The connection mode of bearing plate 11 and four-wheel vehicle 1 wheel axle is angle steel welding.

[0042] The vertical drawing frame 12 of the drilling rod is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com