Tail gas aftertreatment package

An exhaust gas post-treatment and exhaust gas technology, which is applied in the direction of exhaust devices, mufflers, engine components, etc., can solve problems such as increased fuel consumption and increased system back pressure, and achieve the effect of improving mixing uniformity and improving disassembly convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

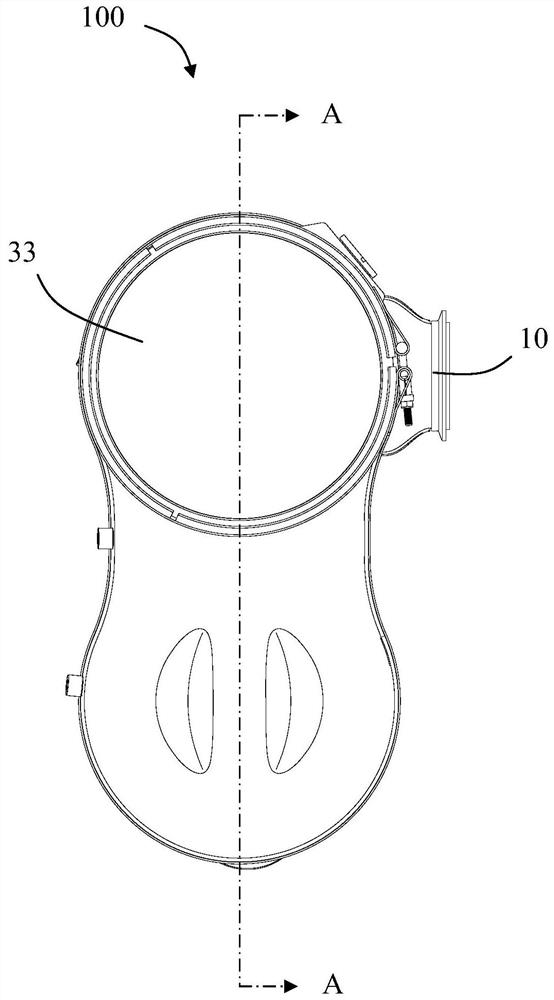

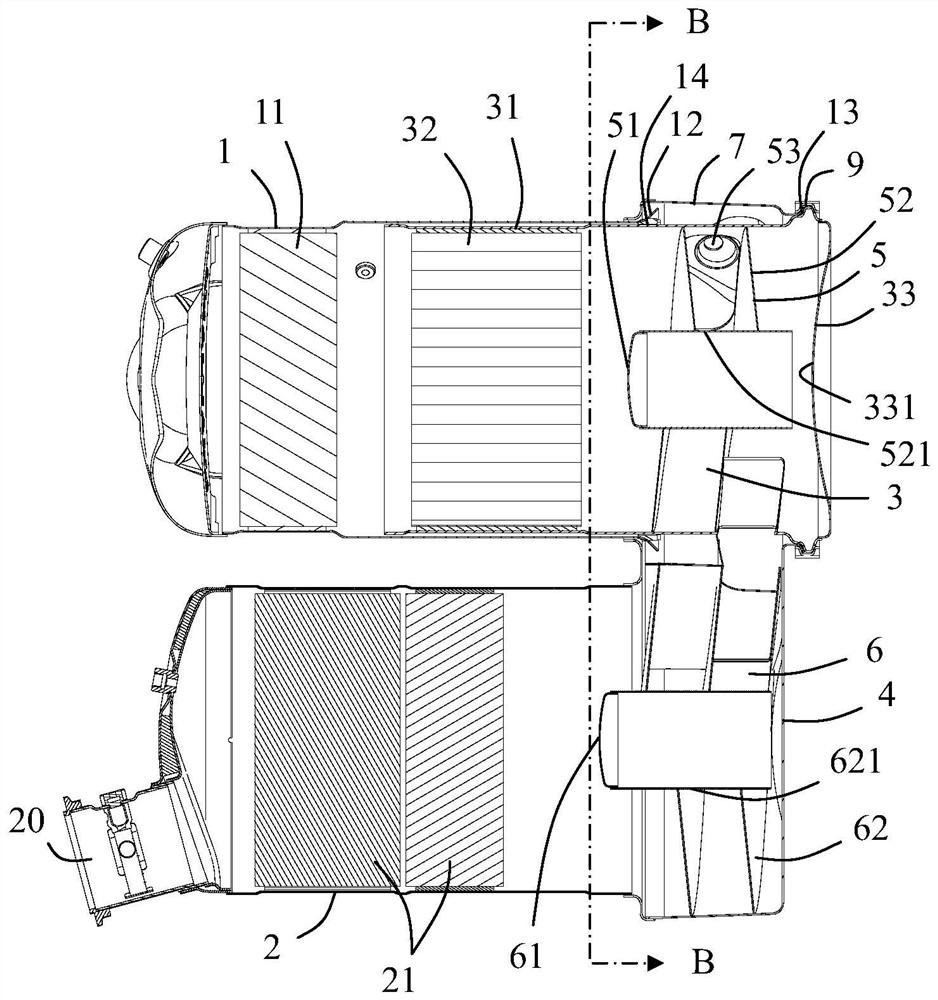

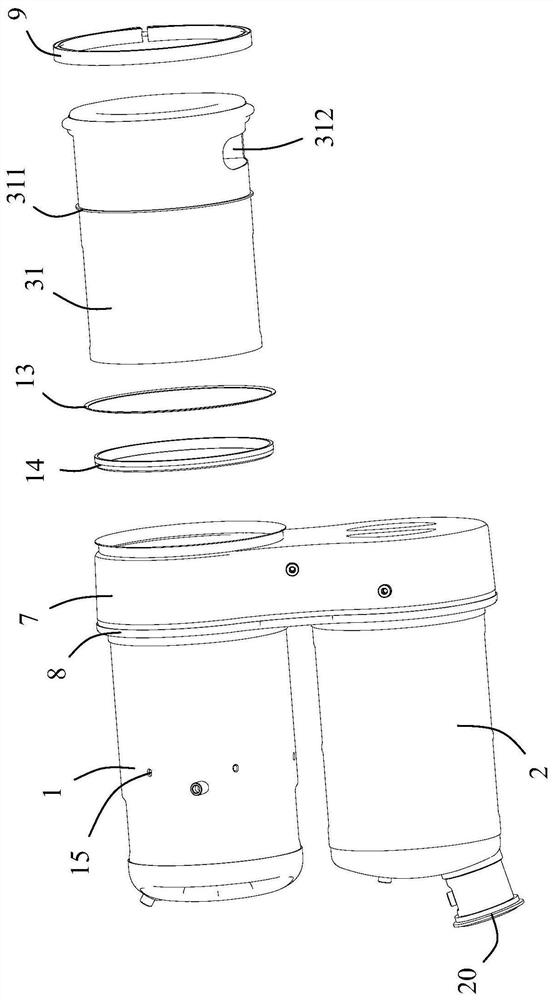

[0024]Please refer toFigure 1 to 4 As shown, the present invention discloses an exhaust gas post-processing package 100 including a first housing 1, encapsulated a first carrier 11 in the first housing 1, communicated with the first housing 1. The airflow inlet 10, the second housing 2 arranged side by side with the first housing 1, encapsulated in the second carrier 21 in the second housing 2, located in the second carrier 21 in the second carrier 21 in the second carrier 21. The mixing assembly 4 is detachably mounted in the axial direction of the first housing 1 in the third carrier assembly 3 in the first housing 1, and an air flow exit with the second housing 2. 20.

[0025]The third carrier assembly 3 includes a third housing 31, encapsulated a third carrier 32 in the third housing 31 and a first mixer 5 located downstream of the third carrier 32.

[0026]The mixing assembly 4 is provided with a second mixer 6 and a fourth housing 7, the second mixer 6 is fixed within the fourth hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com