High-thermal-conductivity LED lamp

A technology of LED lamps and high thermal conductivity, applied in the field of lighting, can solve the problems of slow heat dissipation of LED lamp beads, uneven heat dissipation surface, and shortened product life, so as to save the PCB assembly process, reduce the light decay rate, and improve the product life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

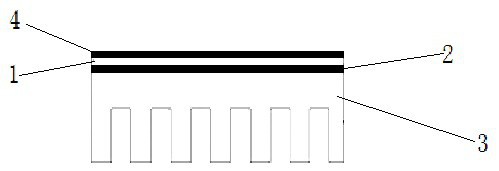

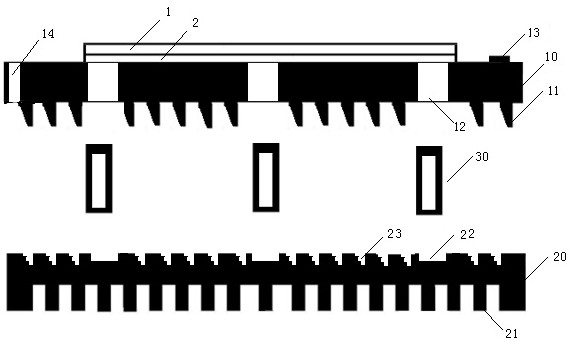

[0026] The preparation method of the high thermal conductivity LED lamp of Example 1 is as follows: directly use the heat sink 3 as the electronic circuit board, directly press the copper layer 1 and the insulating layer 2 on the circuit to the heat sink 3, then etch the circuit, and then apply a resistive layer. Soldering layer 4 and pasting of LED lamp beads; the use of aluminum substrate and heat-conducting material is directly omitted; the heat-conducting path is LED-copper layer 1-insulating layer 2-radiator 3.

[0027] Adopting the structure of Embodiment 1 of the present invention can improve the heat dissipation effect of the product, reduce the pearlescent decay rate of the LED lamp, increase the product life, reduce the difficulty of the product assembly process, and save the PCB assembly process.

[0028] In the process of trial-manufacturing Example 1, the inventors further found that the above-mentioned process needs to adopt a pressing process, and when the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com