Intelligent reinforcing steel bar weighing and length measuring mechanism and weight deviation marking all-in-one machine comprising the same

A technology of weight deviation and length measurement, applied in the field of steel bar experimental tools, can solve the problems of unclear gauge length, slow marking speed, low work efficiency, etc., and achieve the effect of accurate marking spacing, improving efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

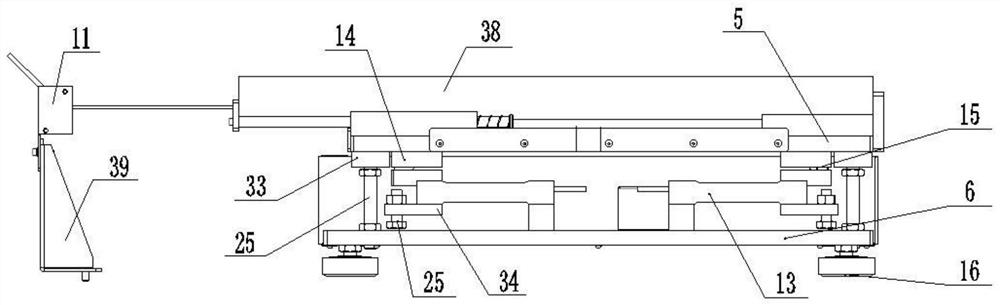

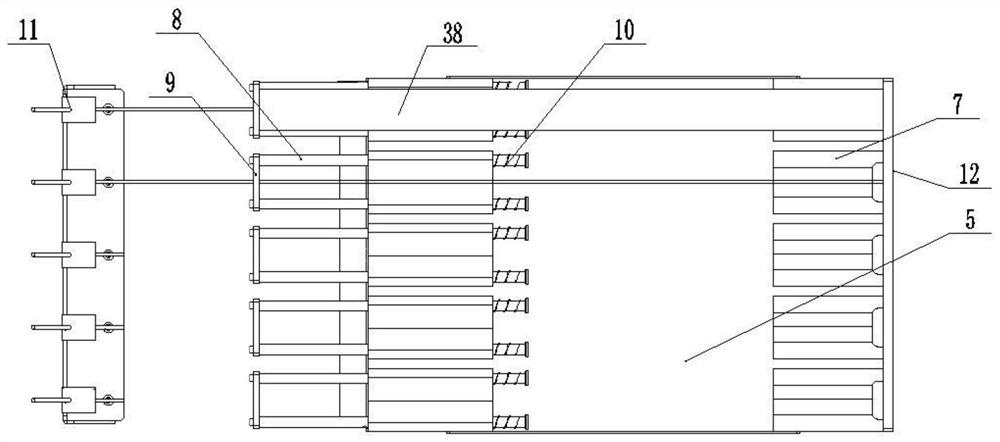

[0038] Such as figure 1 and figure 2 An intelligent steel bar weighing and length measuring mechanism is shown, including a laser length measuring unit and a weighing unit,

[0039] The laser length measuring unit includes 5 groups of laser displacement sensors 11 and sensor fixing brackets 39, which can simultaneously measure the size of multiple steel bars,

[0040] The weighing unit includes a horizontally placed bracket base plate 5 and a bottom base plate 6, on the bracket base plate 5 corresponding to the laser displacement sensor 11, 5 sets of steel bar placement components are arranged, and the bottom of the bracket base plate 5 is equipped with a dust-proof sheet metal, Prevent dust from falling into the bottom substrate 6; a load cell 13 is installed on the bottom substrate 6, and the top of the load cell 13 is floatingly connected to the bottom of the bracket substrate 5 through a connecting plate 14 and a steel ball 15. The load cell 13 The two sides of the two ...

Embodiment 2

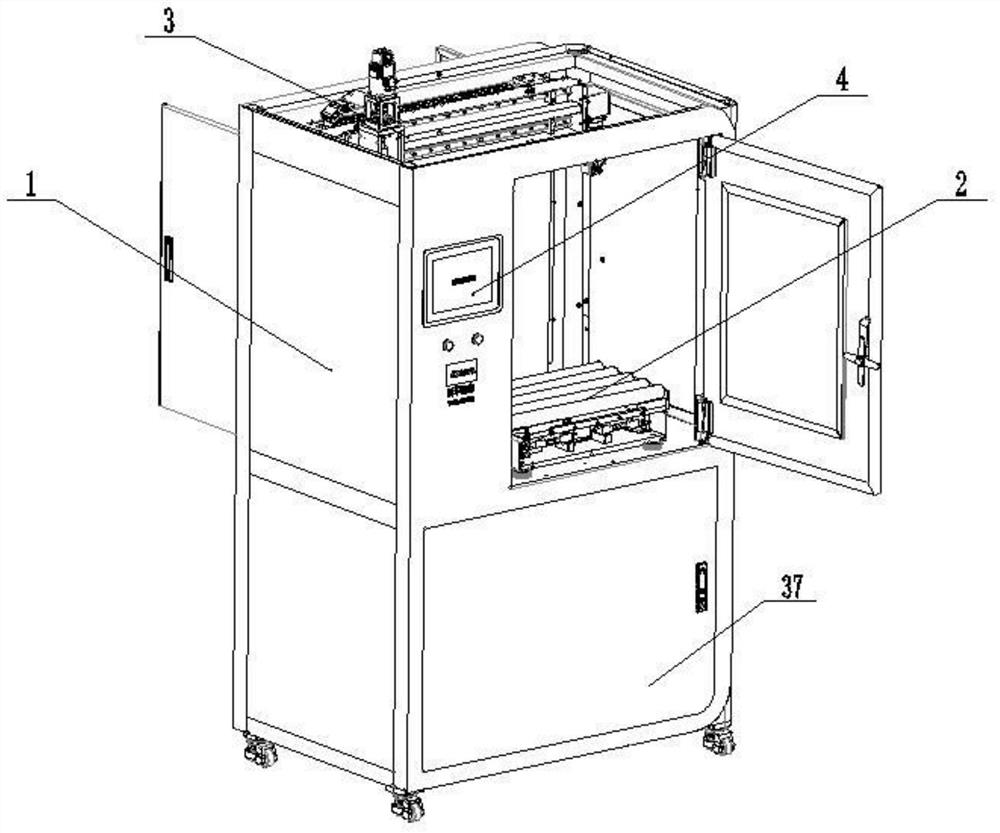

[0046] Such as Figure 3-Figure 4 An intelligent steel bar weight deviation marking all-in-one machine shown includes a cabinet body 1, a laser marking unit 3 and a weighing and length measuring mechanism 2 described in Embodiment 1 are arranged inside the cabinet body 1, and the cabinet body 1 is A man-machine interface 4 is provided, and a tool box 37 is installed at the lower part of the cabinet 1,

[0047] The laser marking unit 3 includes a laser assembly 17, an X-axis motion mechanism 18, and a Z-axis motion mechanism 19. The X-axis motion mechanism 18 is horizontally arranged, and the Z-axis motion mechanism 19 is connected to the X-axis motion mechanism 18 and can move in X direction, the laser assembly 17 is connected to the bottom end of the Z-axis motion mechanism 19 and moves up and down along the Z-axis motion mechanism 19;

[0048] The weighing and length measuring mechanism 2 is located below the laser marking unit 3 and placed parallel to the X-axis motion mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com