Degradation equipment residual life prediction method considering multiple uncertainties

An uncertainty and life prediction technology, applied in computer-aided design, design optimization/simulation, special data processing applications, etc., can solve the problems of lack of nonlinear accelerated degradation modeling and remaining life prediction methods, measurement errors, etc. The effect of small sample size and short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0199] Example application analysis

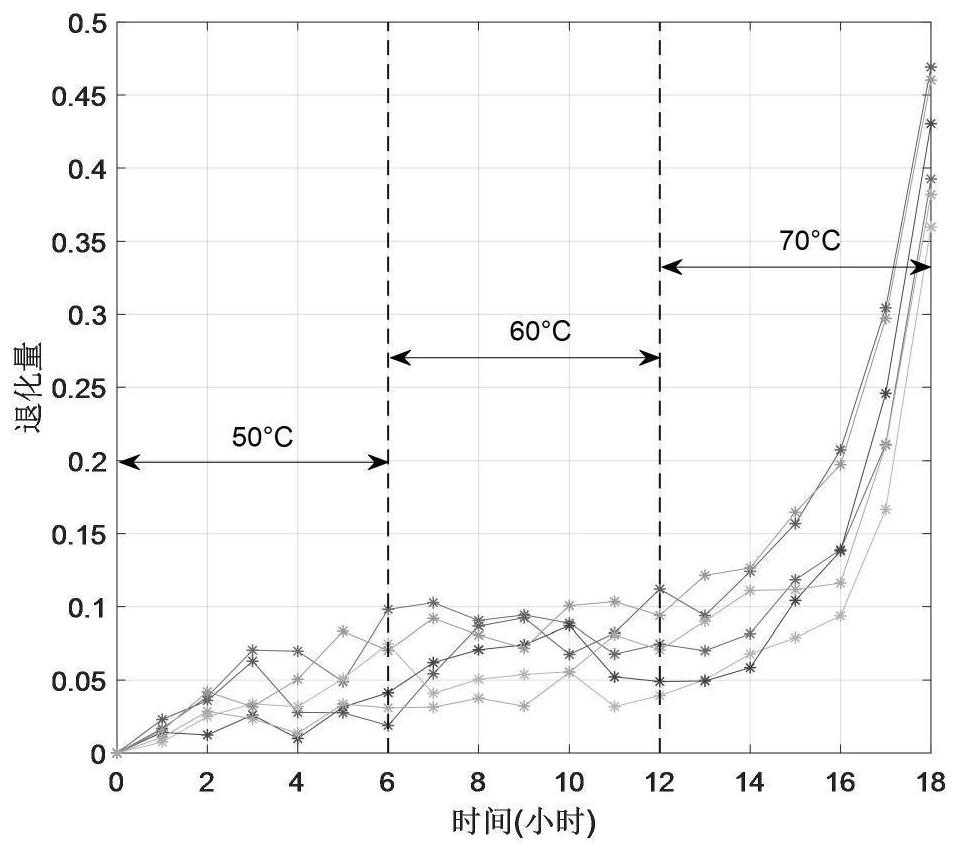

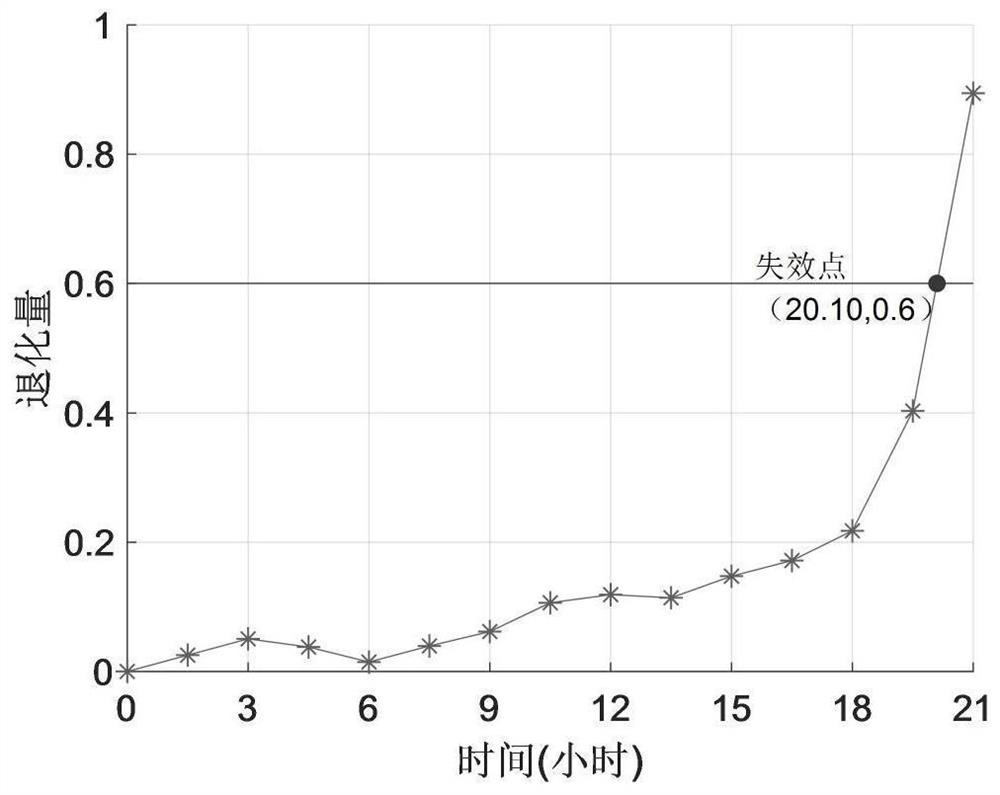

[0200] Taking the gyroscope in a certain type of inertial navigation system as an example, the validity of the method proposed in the present invention is verified. Considering that temperature is the main factor causing gyroscope drift, the relationship between drift degradation data and temperature stress conforms to the Aronis model. In the step stress accelerated degradation test, the threshold is set at 0.6° / h, and the step stress is 50°C, 60°C and 70°C. The gyroscope works continuously in the actual working environment, automatically records the drift degradation data every hour, and records 6 times for each stress. The test results of the six samples are as follows figure 1 shown.

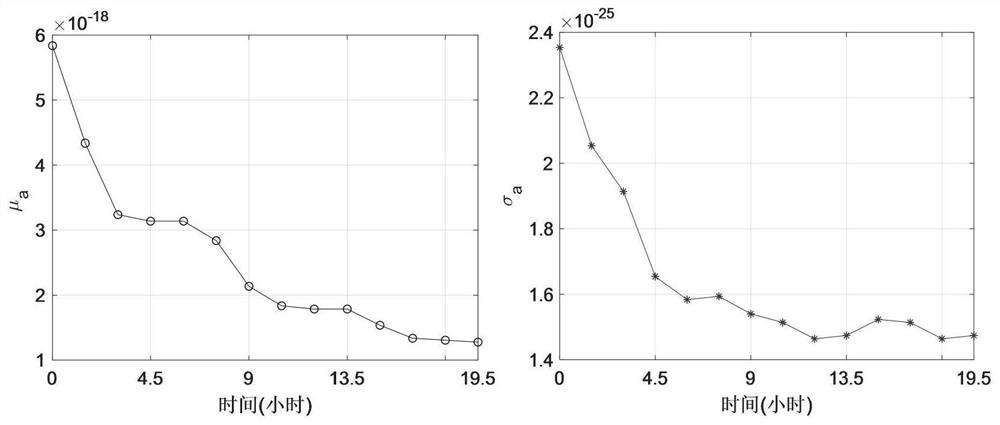

[0201] According to the parameter estimation method proposed in step 4, the estimated values of the unknown parameters in the model can be obtained by using the improved MLE-SIMEX method, as shown in Table 1.

[0202] Table 1 Estimated values of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com