Reed-based biomass rod utilization production system

A production system and biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems that biomass particles are easy to loosen, affect the quality and efficiency of biomass particle production, and the exhaust effect is not good, so as to achieve the utilization The value is obvious, the effect of improving firmness and accelerating exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

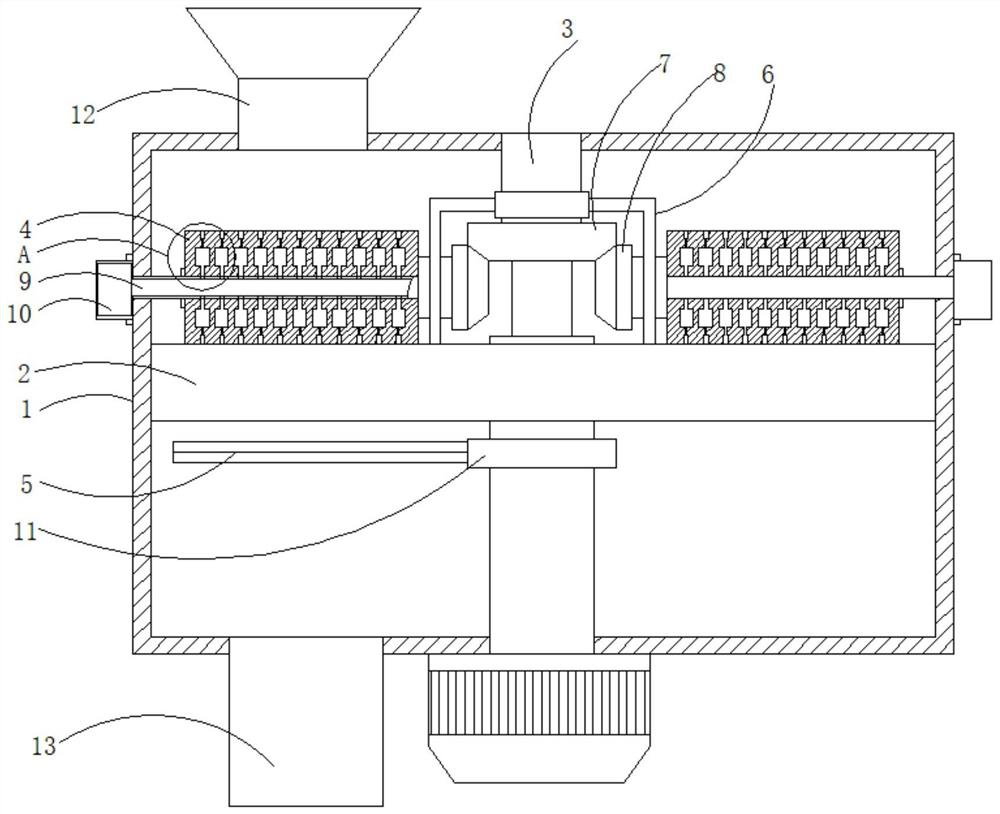

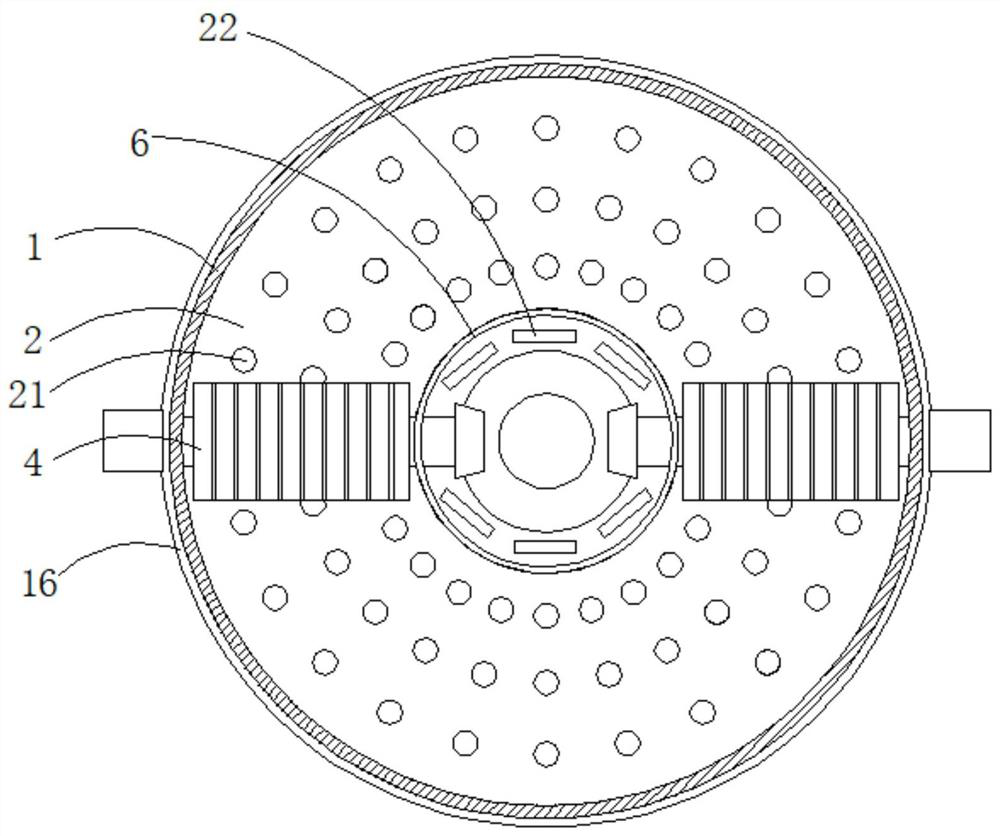

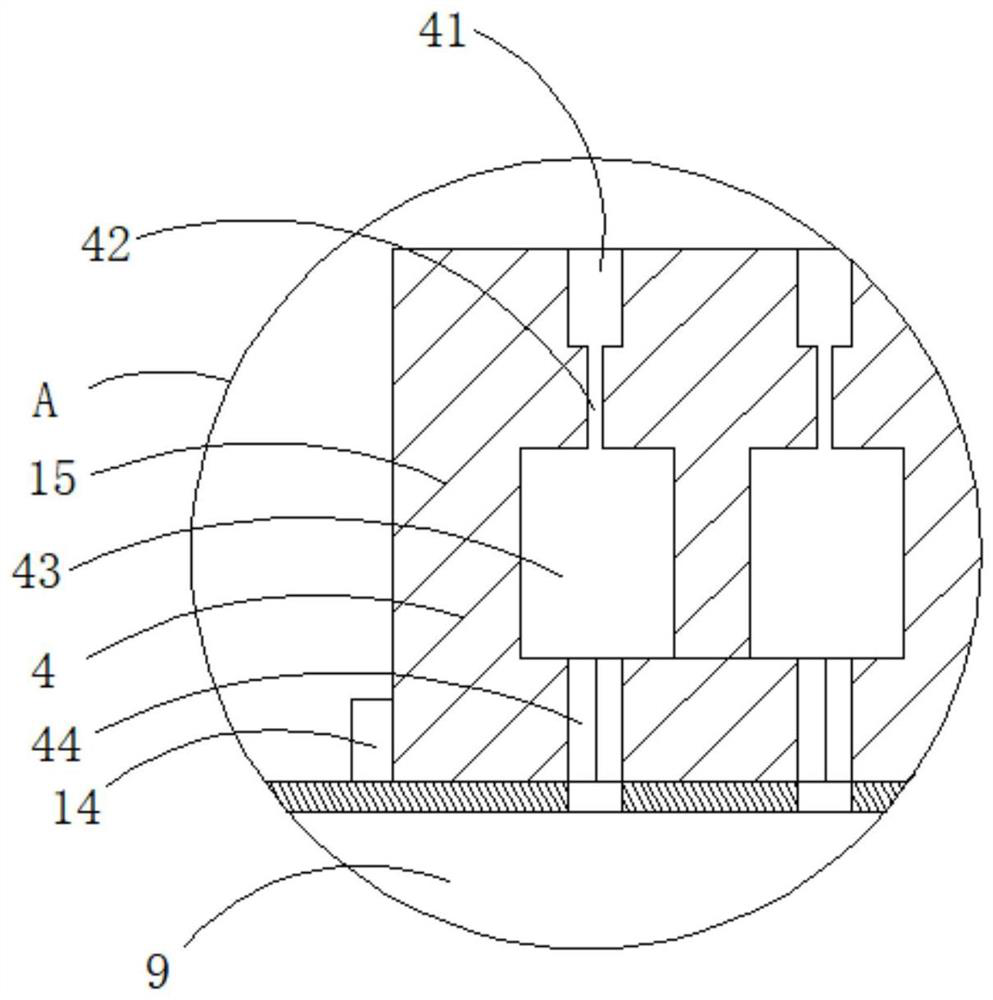

[0022] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

[0023] Benchiomyb material rods utilize production systems include chippers, pulverizer, dry fan, dust removal machine, granulation device. The chipper makes the reeds, and then feeds the reed piece into the pulverizer by the screw feeder to obtain a criminal powder, and the dust is removed by dusting machine, and the dry fan is used to carry out the powder. Drying, the water content of the crescent powder conforms to the granulation standard, the granulation device for granulation of the phosgent powder to obtain a group of biomass rod granules.

[0024] In this embodiment, the pulverizer, a pulverizer, a drying fan, and dust collectors, which can realize the target function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com