Isothermal die forging forming process for passenger observation window frame precision die forging

A forming process and isothermal die forging technology, which is applied in the field of aluminum alloys and can solve the problems of lack of production capacity of aviation aluminum alloy precision die forging products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

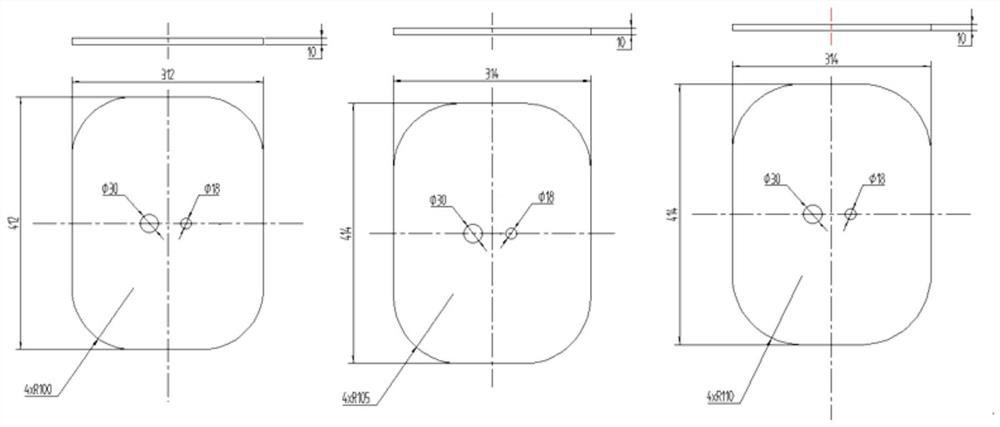

[0055] The preparation process is the same as Comparative Example 1, and the following improvements have been made: (1) Optimizing the use of 12mm rolled slabs, optimizing the size of the billets, increasing 4mm in the length direction and width direction, 2mm in the thickness direction, and the fillet size becomes 110mm, the maximum outer window frame size of the blank is determined to be 418+2×318+2×12+1(R110)mm.

[0056] (2) The final pressure is 1 fire, and the pressure is controlled according to 5000 tons, so that the underpressure of the window frame is 1.5 ~ 3mm;

[0057] (3) Roughly process the inner and outer burrs after the final pressure 1 fire, and the residual burrs are 8-10mm; the burrs on the top of the ribs are polished flat and not polished into rounded corners;

[0058] (4) The final pressure is 2 fires, and the pressure is controlled according to 8500 tons, so that the underpressure of the window frame is 0 ~ 1mm, and the final pressure parts with qualified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com