Selective laser melting forming method for nickel-based superalloy

A nickel-based superalloy, laser selective melting technology, applied in the field of additive manufacturing, can solve the problems of long preparation cycle and complex process, achieve the effect of improving comprehensive mechanical properties, reducing production cycle, and improving industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

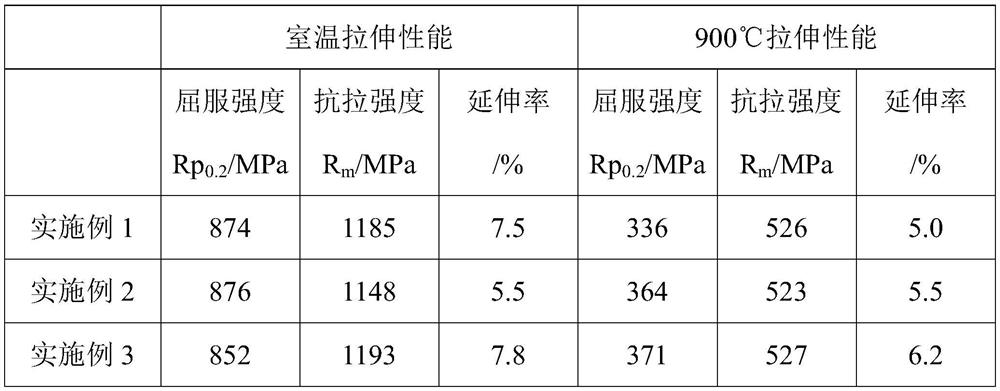

Embodiment 1

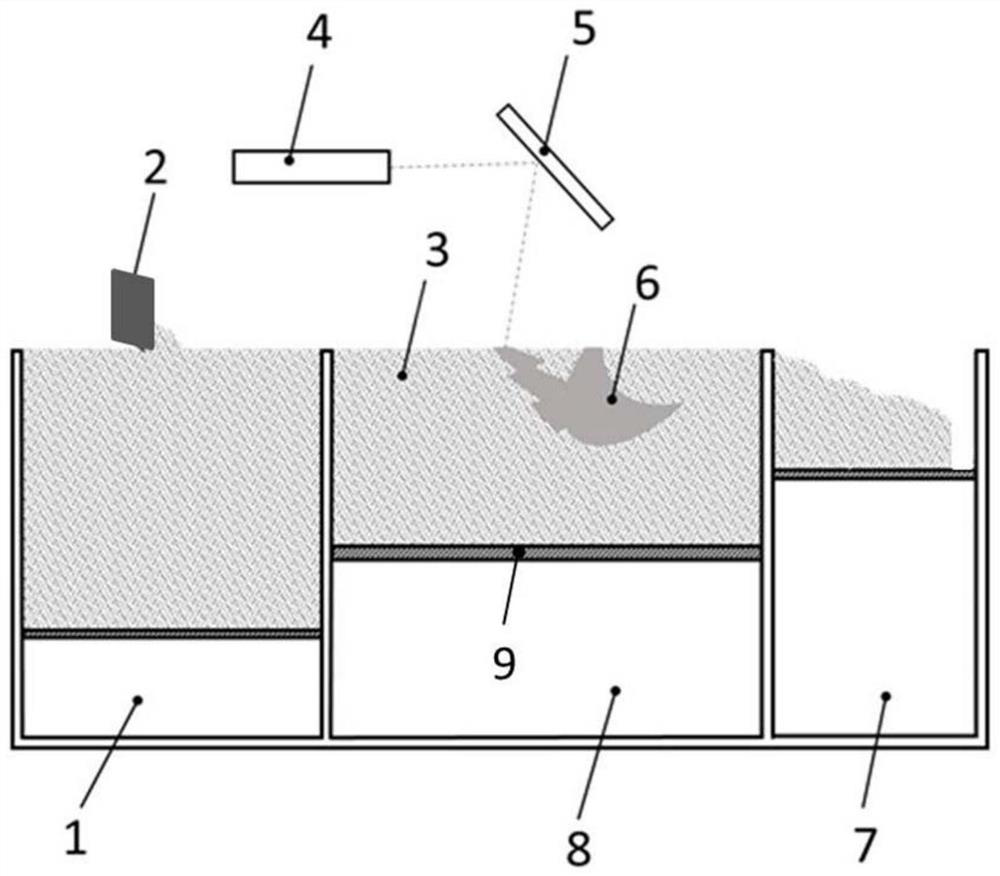

[0084] This embodiment provides a method and device for laser selective melting and forming of a nickel-based superalloy. The structural schematic diagram of the device is as follows figure 1 shown.

[0085] The device includes a powder supply cabin 1, a scraper system 2, a laser system 4, a laser galvanometer system 5, a forming cabin 8 and a powder recovery cabin 7;

[0086] The powder supply cabin 1, the forming cabin 8 and the powder recovery cabin 7 are sequentially connected; the scraper system 2 can move in parallel from the powder supply cabin 1 to the powder recovery cabin 7; the laser system 4 and the laser galvanometer system 5 are suspended Above the powder supply cabin 1 and the forming cabin 8;

[0087] The powder supply cabin 1 , the forming cabin 8 and the powder recovery cabin 7 are all provided with a liftable platform 9 .

[0088] The method for performing laser selective melting and forming of nickel-base superalloy by using the above-mentioned device com...

Embodiment 2

[0095] This embodiment provides a method for laser selective melting of a nickel-based superalloy, and the device used in the method refers to the device in Embodiment 1.

[0096] The method comprises the steps of:

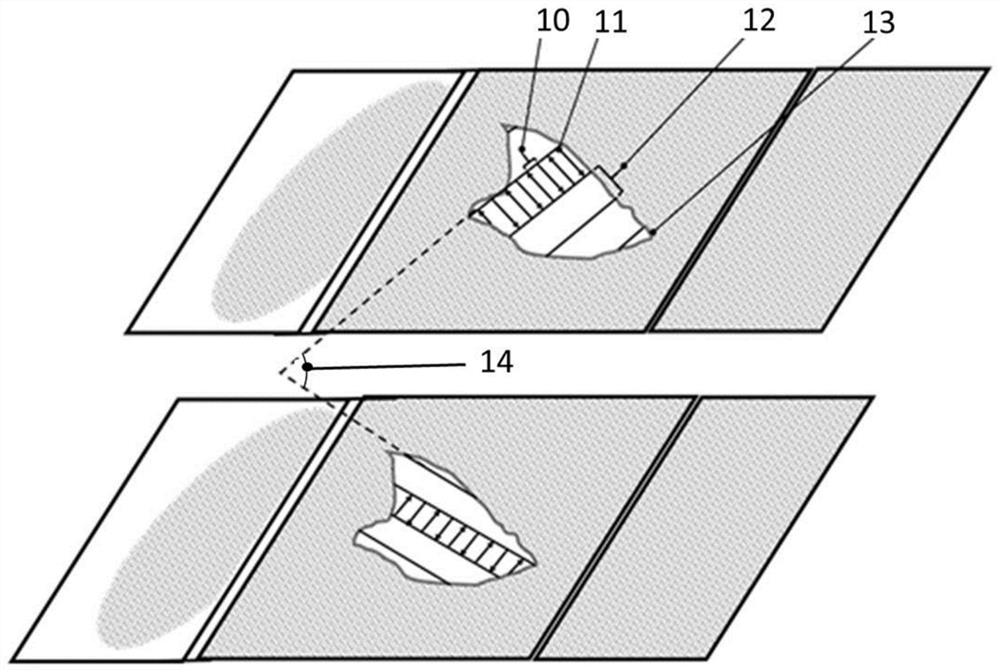

[0097] (1) The average particle size is 28μm, the Hall flow rate is 20s, and the bulk density is 4.4g / cm 3 , the K438 nickel-based superalloy powder with a spherical rate of 88% is spread on a platform substrate at 200 ° C, and the thickness of each layer of powder is 35 μm. Scanning and contour laser scanning, the scanning methods include strip scanning and rotary scanning, the strip width of strip scanning is 12mm and there is no gap between each strip, during the scanning process, the strip between adjacent two layers rotates clockwise 31°;

[0098] The process parameters of the physical laser scanning include: laser spot diameter of 110 μm, laser power of 220 W, laser scanning speed of 950 mm / s, adjacent laser scanning lines in opposite directions with a spa...

Embodiment 3

[0102] This embodiment provides a method for laser selective melting of a nickel-based superalloy, and the device used in the method refers to the device in Embodiment 1.

[0103] The method comprises the steps of:

[0104] (1) The average particle size is 30μm, the Hall flow rate is 15s, and the bulk density is 4.5g / cm 3, the K438 nickel-based superalloy powder with a spherical rate of 87% is spread on a platform substrate at 150 ° C, and the thickness of each layer of powder is 32 μm. Scanning and profile laser scanning, the scanning methods include strip scanning and rotary scanning, the strip width of strip scanning is 12 is 9mm and there is no gap between each strip, during the scanning process, the strip between adjacent two layers rotates clockwise 57°;

[0105] The process parameters of the physical laser scanning include: laser spot diameter of 100 μm, laser power of 215 W, laser scanning speed of 900 mm / s, adjacent laser scanning lines in opposite directions with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com