Intelligent flexible production line for metal plate machining in door industry and using method thereof

A flexible production line and sheet metal technology, applied in the field of sheet metal processing, can solve problems such as affecting production efficiency, affecting product quality, and lack of inspection of plates, avoiding waste of materials and energy, enhancing consistency and interchangeability, and improving operation. The effect of reducing the number of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

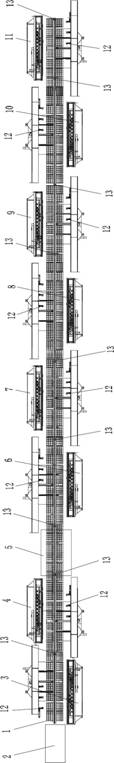

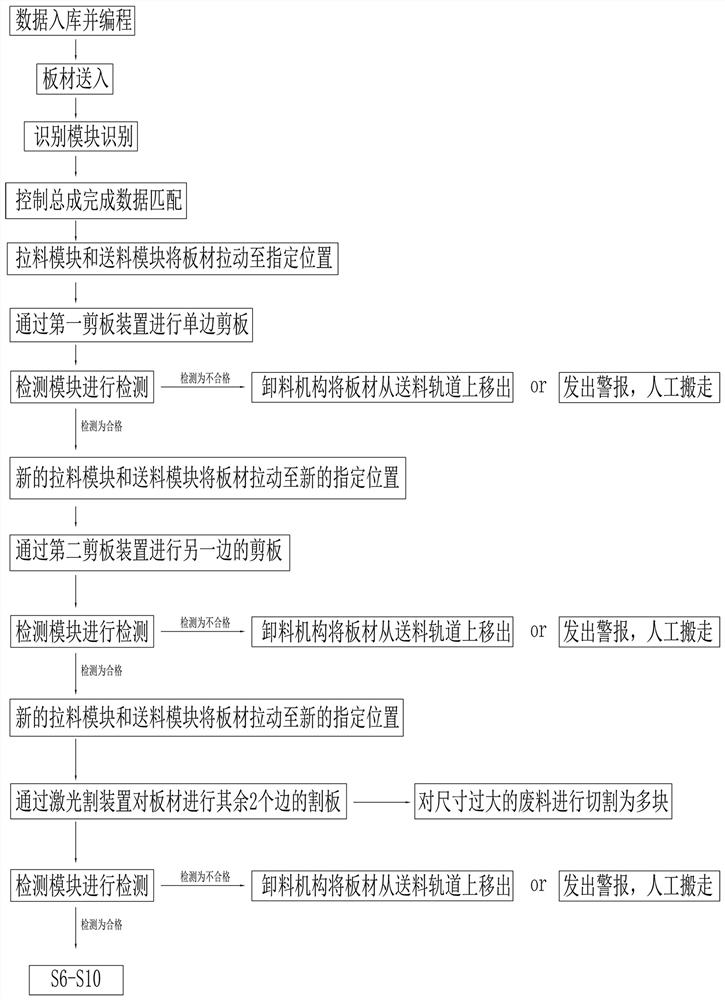

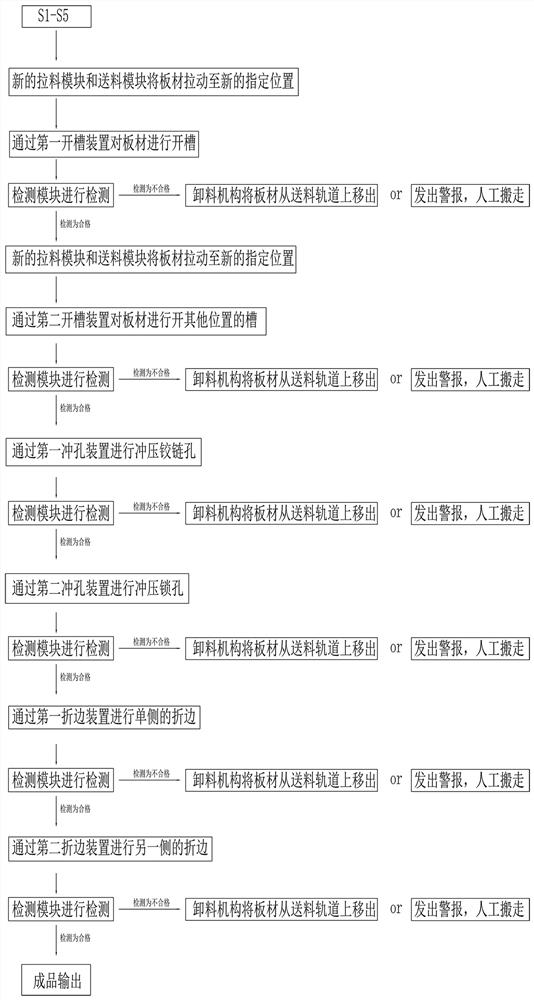

[0041] refer to Figure 1-5 As shown, it is a specific embodiment of the present invention: an intelligent flexible production line for door industry sheet metal processing, including a conveying track, and a combination of two or more of the following modules are arranged on the conveying track: shearing module , laser cutting module, slotting module, punching module, hemming module; the above-mentioned modules can be added or subtracted according to different processes, and can be arranged in different relative positions according to different processes; the above-mentioned Each module is equipped with a feeding module for pulling the sheet; the conveying track is provided with several pulling modules for pulling the sheet and positioning the sheet on a designated area of the conveying track; an identification module and a control assembly are also included ; during processing, pre-data storage and numerical control programming of plates of different sizes or shapes, throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com