Two-dimensional cadmium hydroxide material, preparation method, growth template and application

A technology of cadmium hydroxide and cadmium salt, which is applied in chemical instruments and methods, nanotechnology for materials and surface science, cadmium compounds, etc. Cost, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

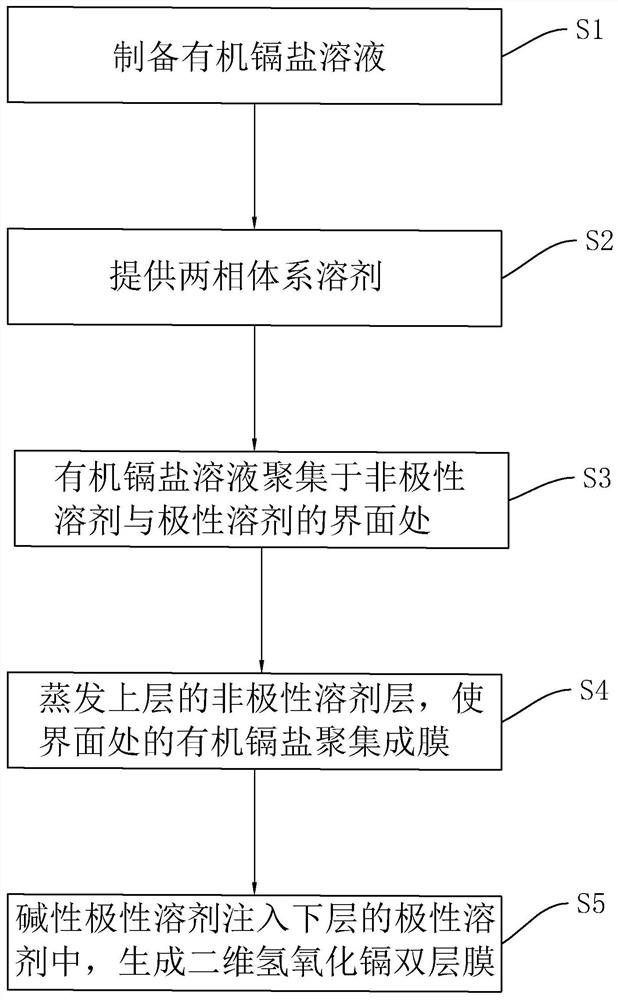

[0072] Embodiment 2 of the present invention discloses a preparation method of a two-dimensional cadmium hydroxide material, such as figure 1 shown, including the following steps:

[0073] S1. prepare organic cadmium salt solution;

[0074] S2. Provide a two-phase system solvent, the upper layer of the two-phase system solvent is a non-polar solvent layer, and the lower layer is a polar solvent layer;

[0075]S3. The organic cadmium salt solution gathers at the interface between the non-polar solvent and the polar solvent;

[0076] S4. Evaporating the non-polar solvent layer located on the upper layer, so that the organic cadmium salt at the interface gathers to form a film as the volume of the non-polar solvent decreases, and floats on the liquid surface of the polar solvent layer;

[0077] S5. Inject the basic polar solvent into the polar solvent in the lower layer to form a two-dimensional cadmium hydroxide bilayer film; when the basic polar solvent is added, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

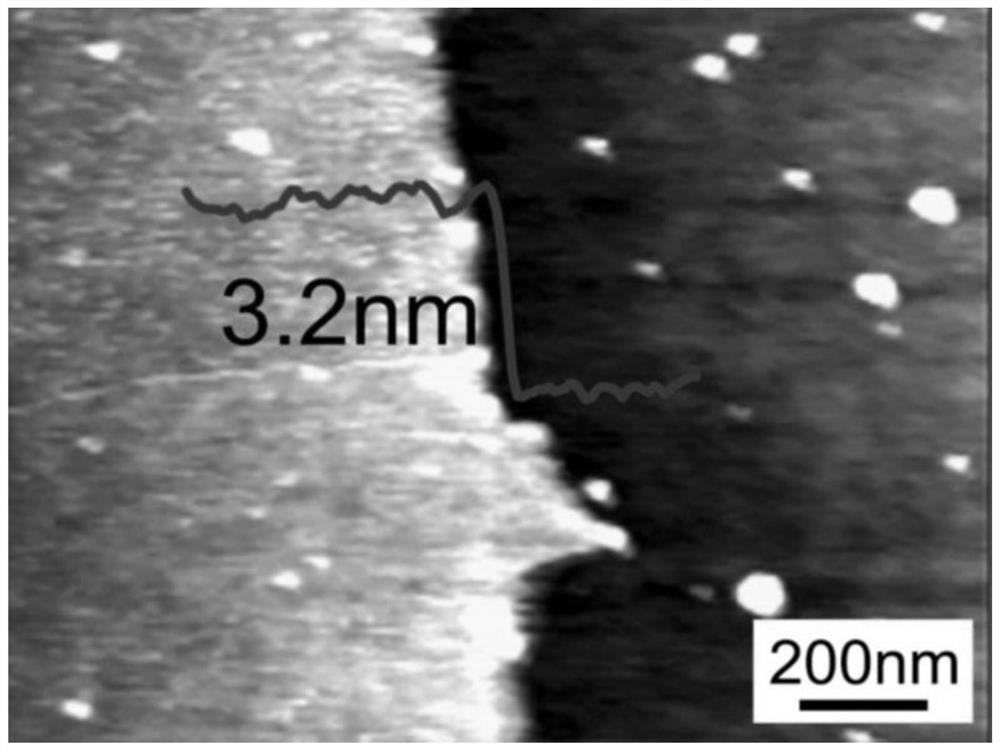

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com