Air-cooled swill treatment grease separation device

A grease separation and air-cooling technology, which is applied in the direction of grease/oily substance/suspton removal device, liquid separation, separation method, etc., can solve the problems of water deodorization, affecting the self-purification of water body, complex swill, etc., and achieve high freezing point and good quality Economic benefits, the effect of improving the effect of oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

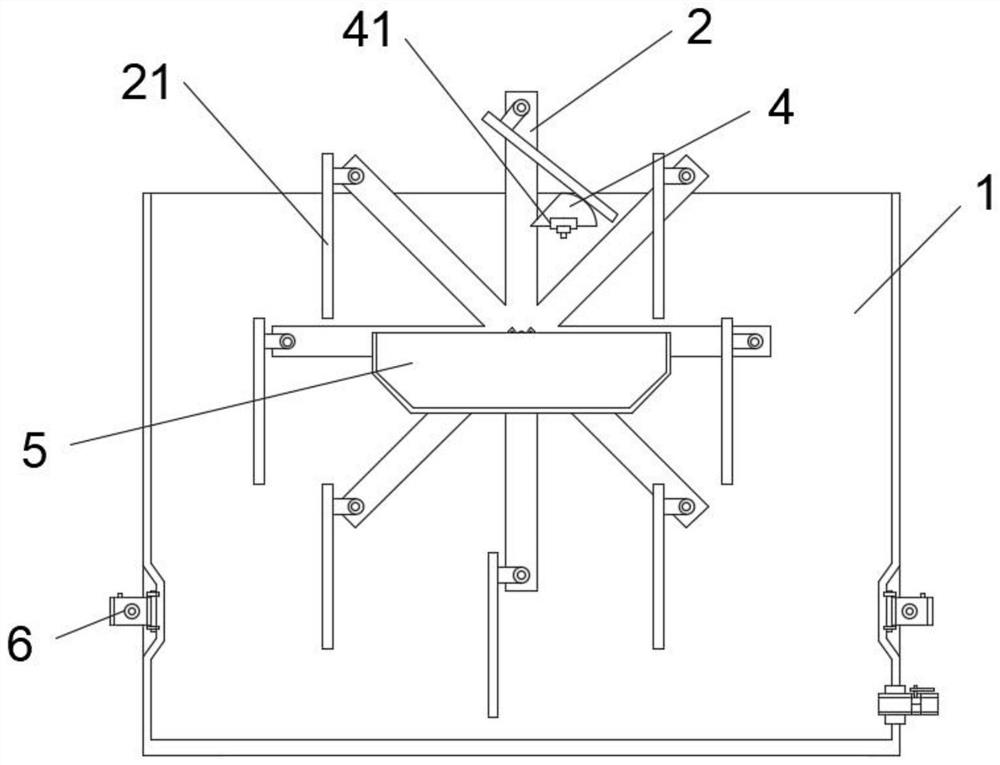

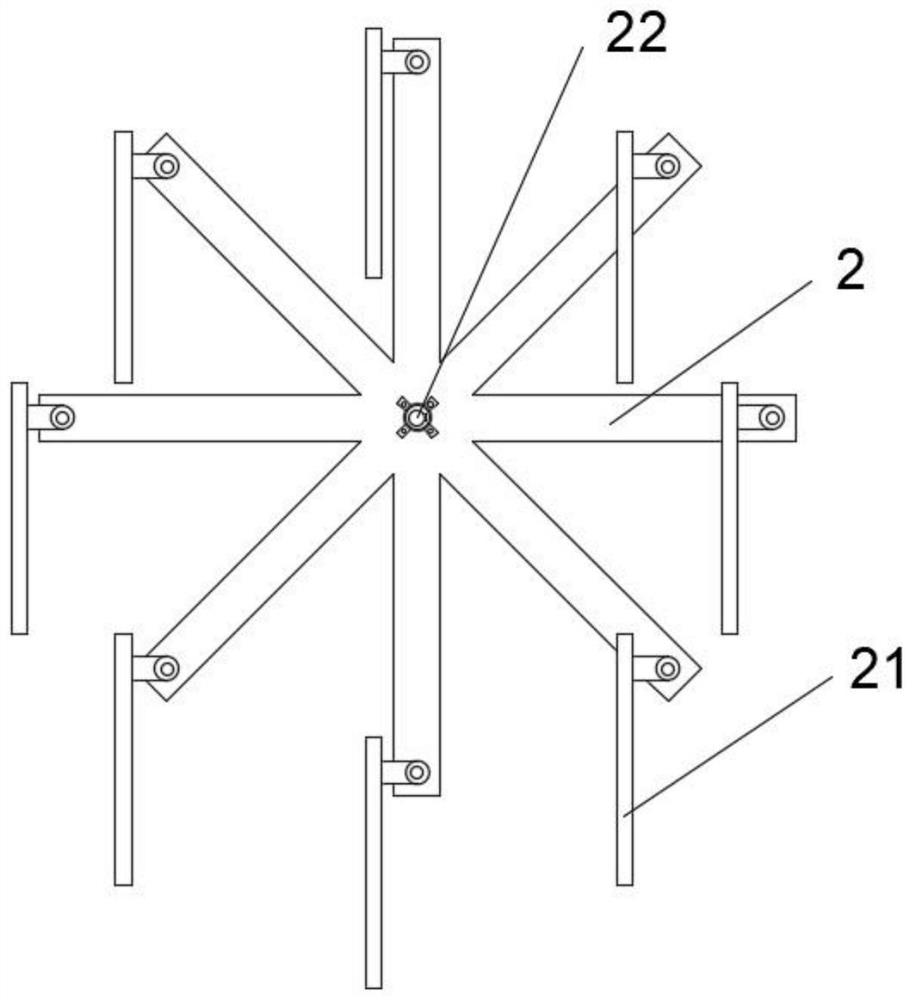

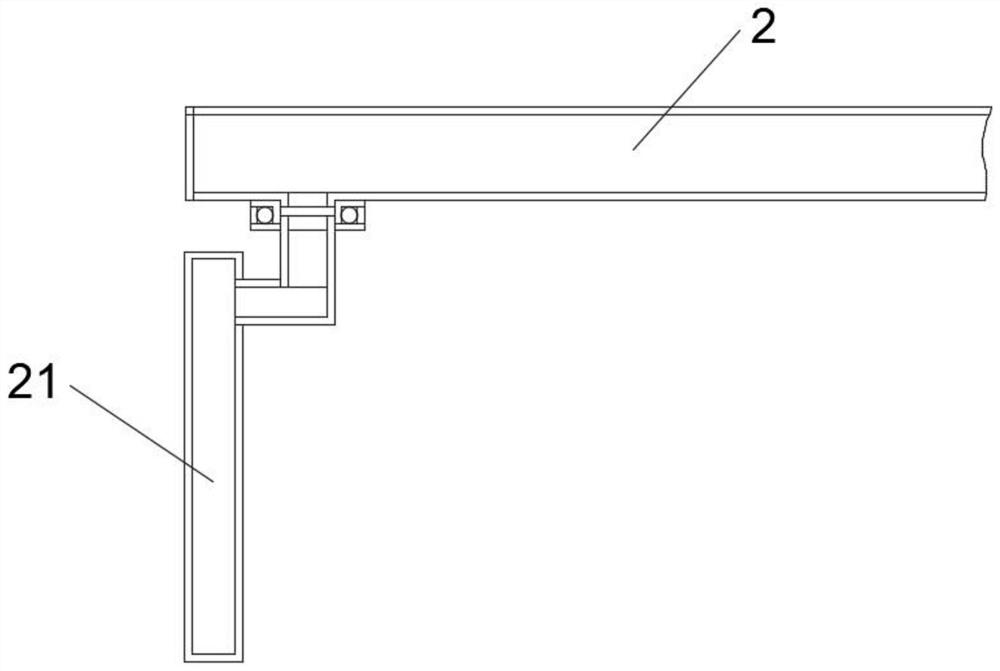

[0026] combine Figure 1-4 , a grease separation device for air-cooled swill treatment, including a separation tank 1, a stirring shaft 2, a driving device 3, a scraper 4, a recovery tank 5, an oil-water stratification device 6 and a casing 7, and the stirring shaft 2 is *-shaped , the stirring shaft 2 is installed on one side of the separation pool 1, the stirring shaft 2 is provided with a pressure valve 22 and the end of the stirring shaft 2 is rotatably provided with a condensation plate 21, and the condensation plate 21 is stirred The bearing ring provided on the surface of the end of the shaft 2 is rotatably connected with the stirring shaft 2, the driving device 3 is connected with the stirring shaft 2, the stirring shaft 2 and the condensation plate 21 are both hollow structures and the The stirring shaft 2 is connected to the external air-cooled refrigeration equipment, the scraping bar 4 is connected to the separation pool 1 and is located on the opposite side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com