Copper electroplating solution for blind hole filling, and application thereof

A copper electroplating and solution technology, applied in the direction of electrodes, electrical components, printed circuits, etc., can solve the problems of affecting the stability of hole filling additives, difficult to fill holes, affecting the plating solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

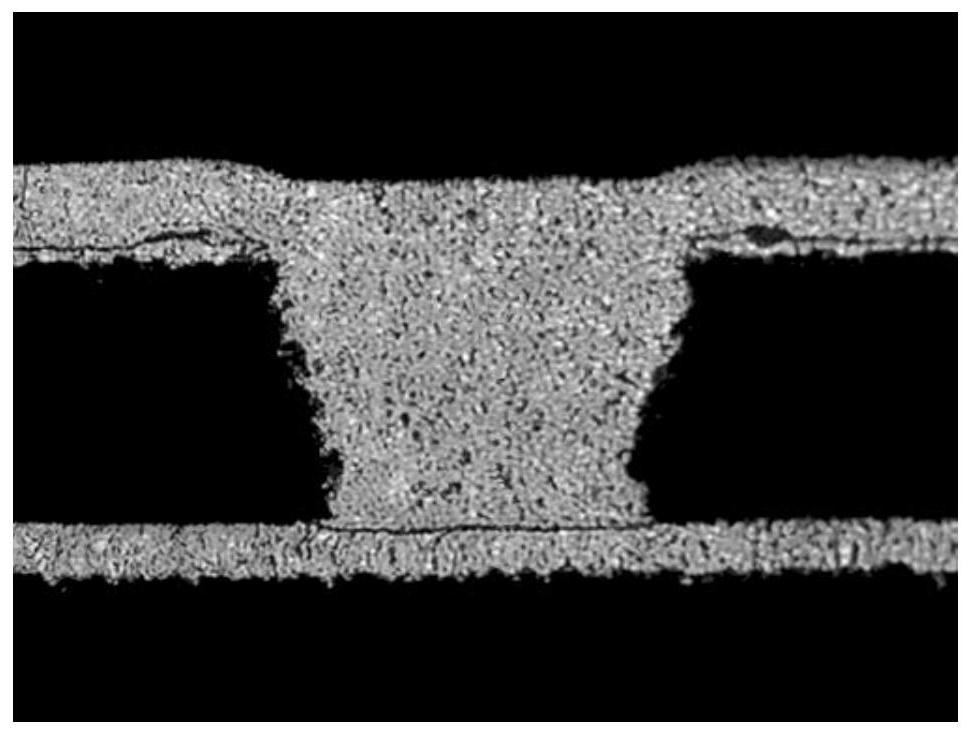

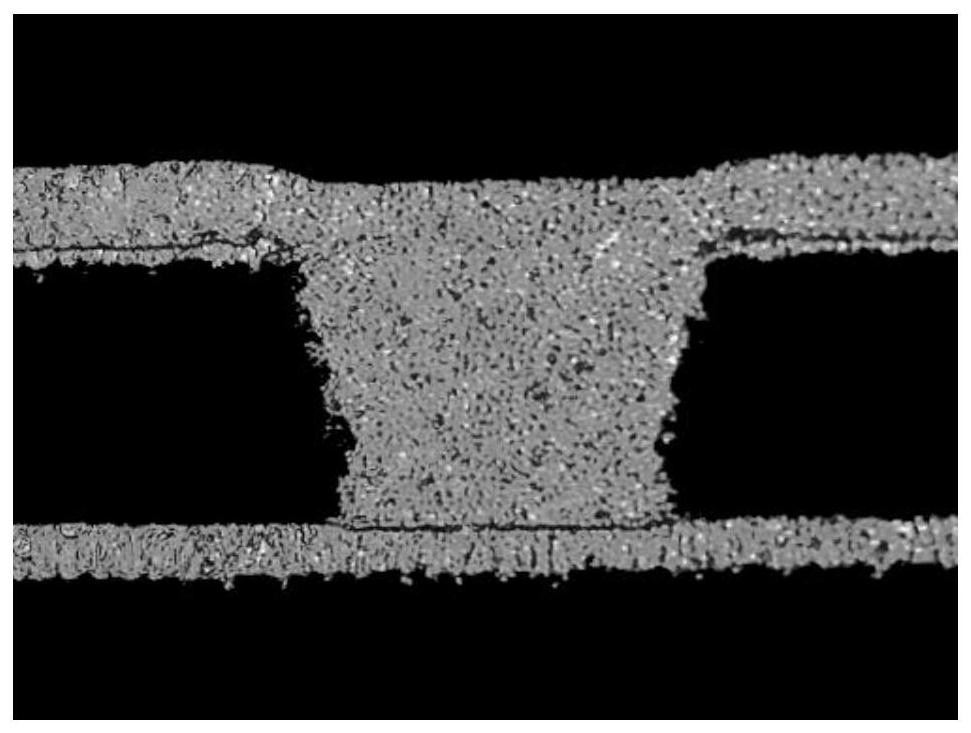

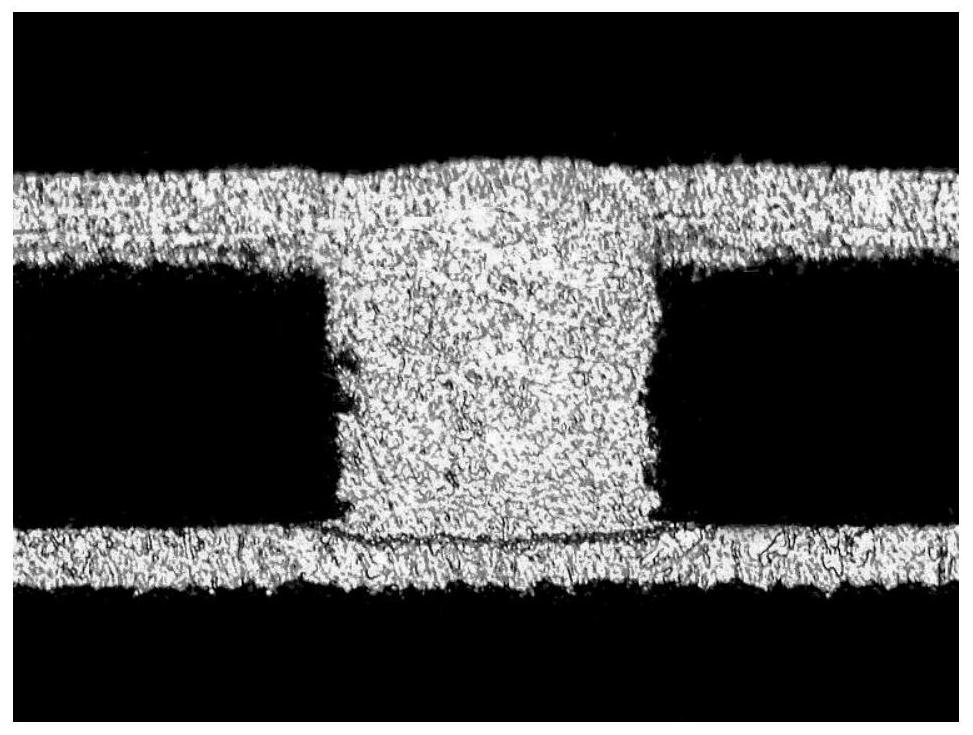

Image

Examples

Embodiment

[0023] A blind hole filling electroplating copper solution, the electroplating copper solution is composed of the following components: sulfuric acid 40-120g / L, copper sulfate pentahydrate 120-240g / L, chloride ion 40-80ppm, accelerator 0.002-0.02 g / L, inhibitor 0.1-0.3g / L, leveler 0.01-0.1g / L, stabilizer 0.002-0.02g / L. The accelerator is sodium 3-mercapto 1-propanesulfonate or sodium polydithiodipropanesulfonate. The inhibitor is one of polyethylene glycol, polypropylene glycol-polyethylene glycol-polypropylene glycol triblock copolymer, ethylene oxide-propylene oxide block copolymer; the molecular weight of the inhibitor For 4000-10000. The leveling agent is a quaternary ammonium compound. The stabilizer is composed of 2,2-bipyridine and N,N,N',N'-tetrakis(2-hydroxypropyl)ethylenediamine according to the mass ratio of 1:(1-4) .

[0024] When the blind hole filling electroplating copper solution is applied, the blind hole is filled and electroplated with a soluble anode. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com