Chemical copper plating solution and preparation method and application thereof

A technology of electroless copper plating and complexing agent, applied in liquid chemical plating, coating, instruments, etc., can solve the problem of poor conductivity of silver paste, and achieve the effect of smooth copper surface, good bonding force and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

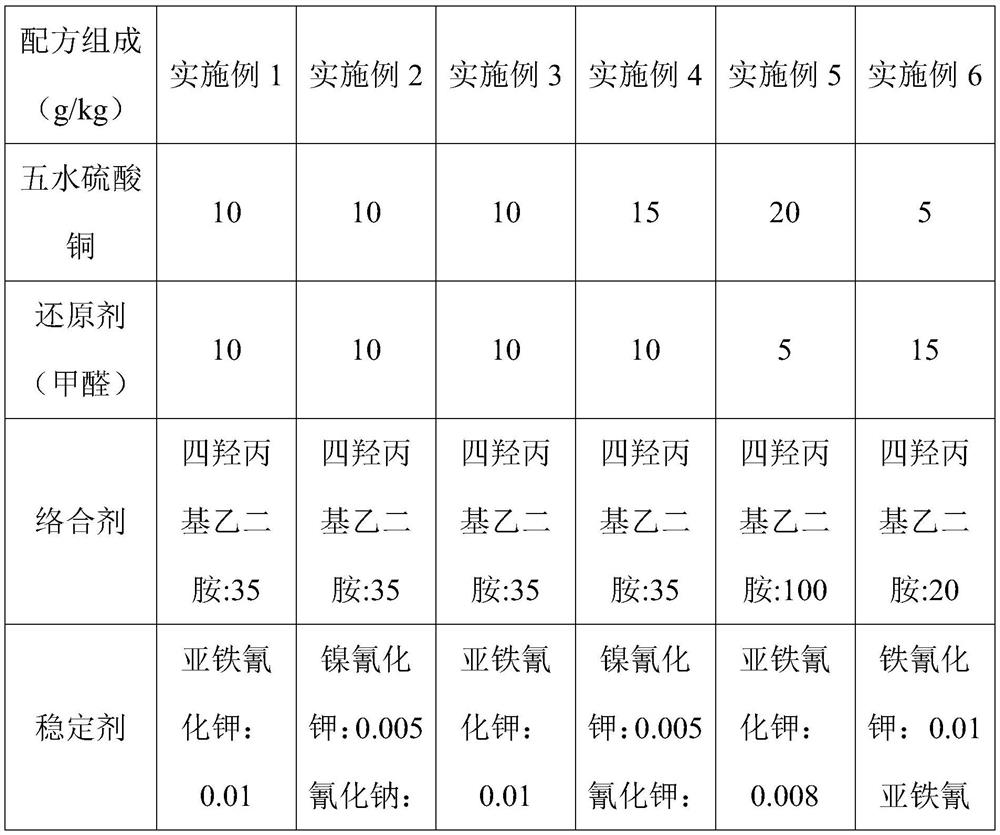

[0035] A kind of electroless copper plating liquid, according to mass concentration meter, described electroless copper plating liquid is made up of the described component of table 1 that is dissolved in deionized water, specifically as follows:

[0036] Table 1

[0037]

[0038]

[0039] The preparation method of above-mentioned electroless copper plating solution comprises the steps:

[0040] Dissolve the complexing agent with deionized water, add copper sulfate pentahydrate while stirring, adjust the pH with a pH regulator after dissolving, then add stabilizer, toughening agent and accelerator and stir evenly; finally add reducing agent and stir evenly, Obtain the electroless copper plating solution.

Embodiment 7

[0042] The difference between this embodiment and embodiment 1 is that the reducing agent is replaced by sodium hypophosphite, and the rest are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com