Assembly type ring rib buckling concrete shear wall system structure and construction method thereof

A concrete shear wall and construction method technology, applied in the direction of walls, building components, building structures, etc., can solve the problems affecting the construction progress and construction effect, and achieve the effect of reducing secondary movement and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

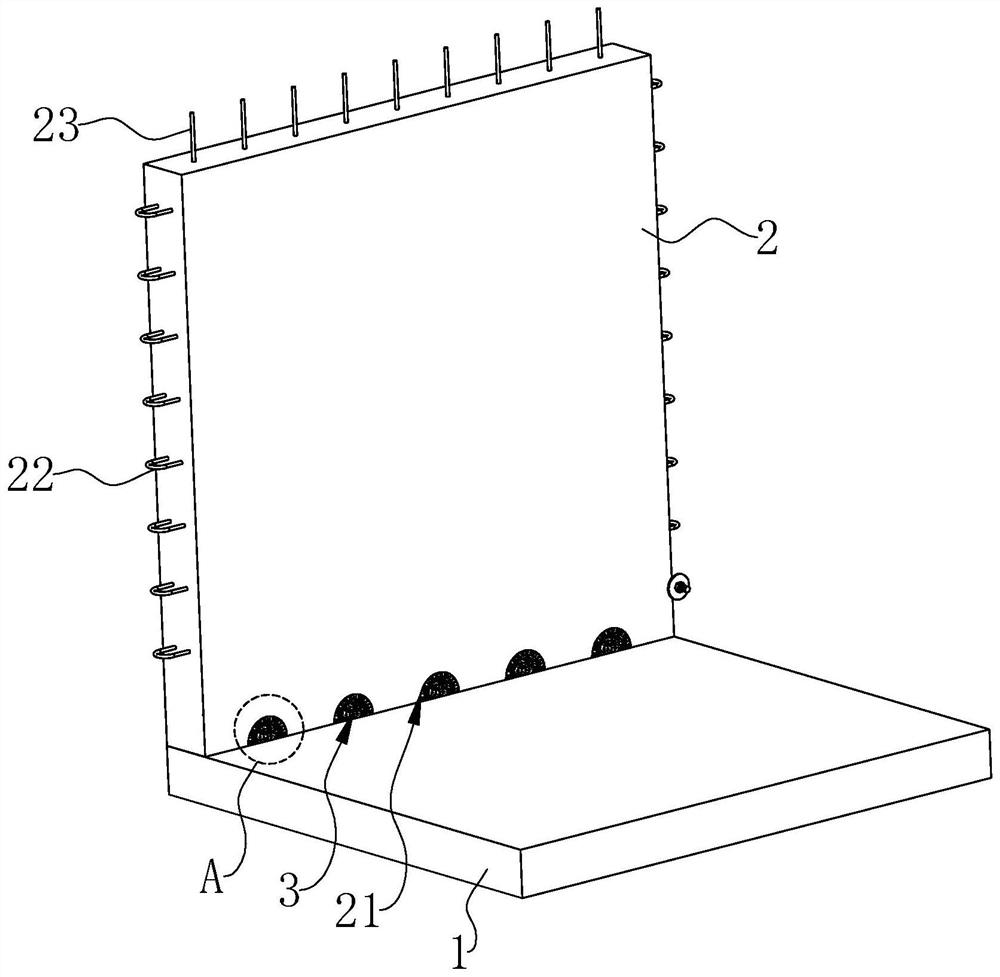

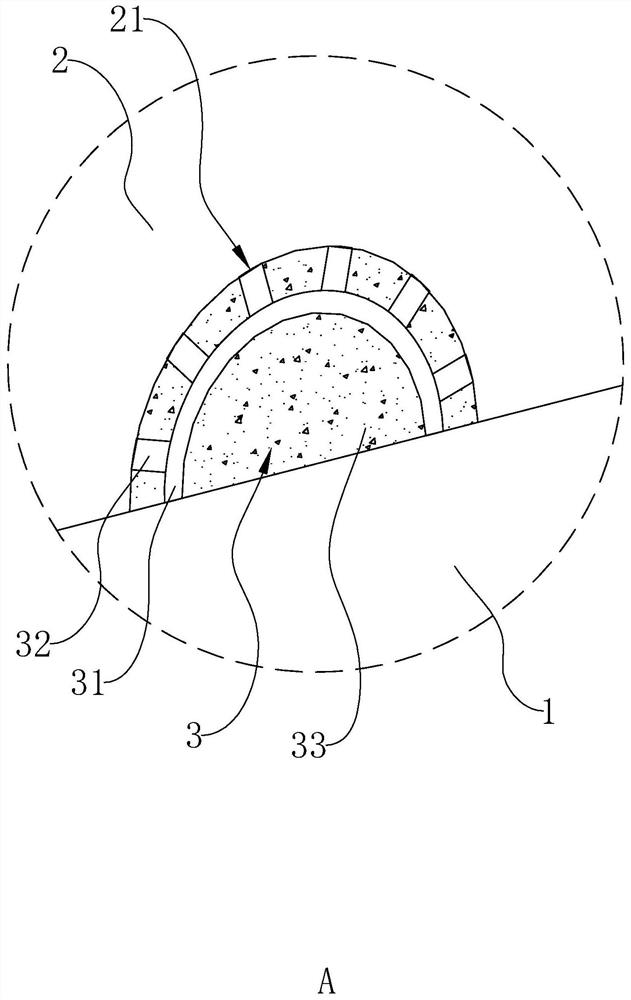

[0045] like figure 1 and figure 2 As shown, a prefabricated ring-reinforced concrete shear wall system mainly includes a floor 1 and a shear wall 2 installed on the upper surface of the floor 1. The lower surface of the shear wall 2 is provided with a space for The groove 21 is a semicircle, the axial direction of the groove 21 is the same as the thickness direction of the shear wall 2 , and the groove 21 runs through the shear wall 2 in the axial direction.

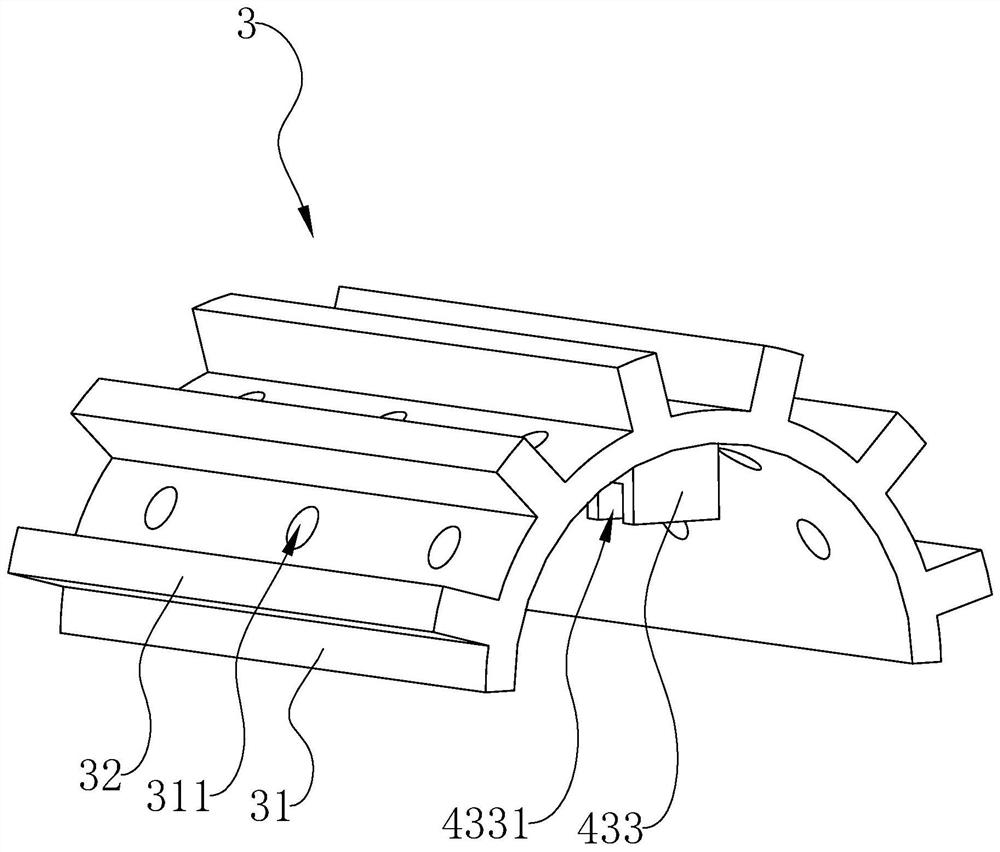

[0046] like figure 2 and image 3 As shown, a positioning member 3 is also provided on the groove wall of the giving way slot 21; The shaft center, and the positioning pipe 31 is penetrated in the relinquishment groove 21, there are several support blocks 32 and are integrally connected to the pipe outer wall of the positioning pipe 31, and the pipe wall of the positioning pipe 31 is also provided with a number of through holes 311, filling The block 33 is formed by the solidification of mortar, so a part of the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap