A strain measuring device based on ultra-large measuring range pdh sensing

A technology of measurement range and strain measurement, which is applied in the field of photoelectric detection, can solve the problems of limited strain measurement range, complex modulation device, and limited sensor, and achieve the effects of frequency stability, avoiding nonlinear influence, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

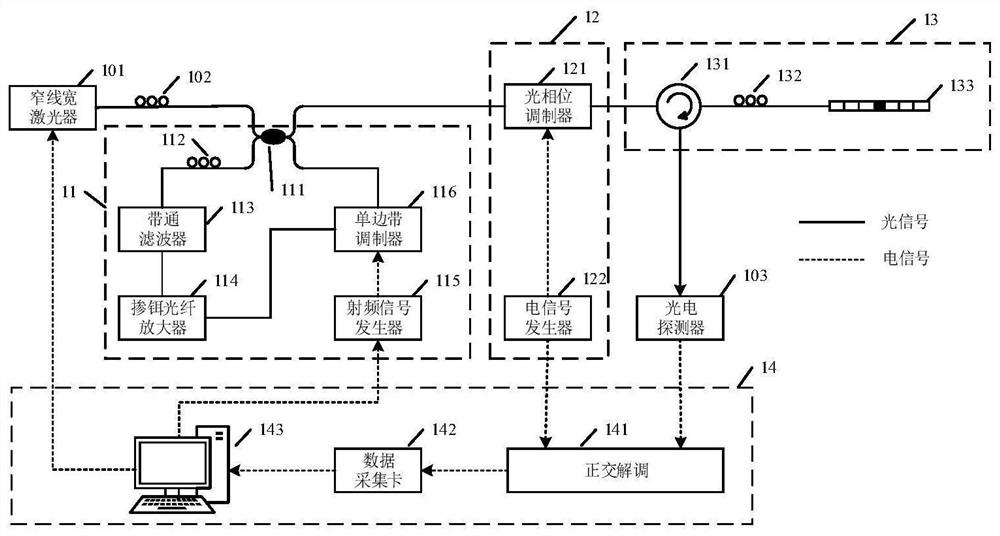

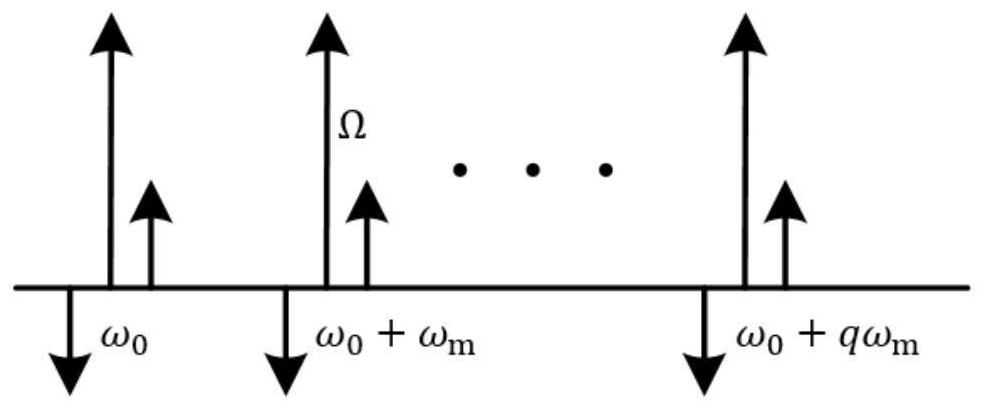

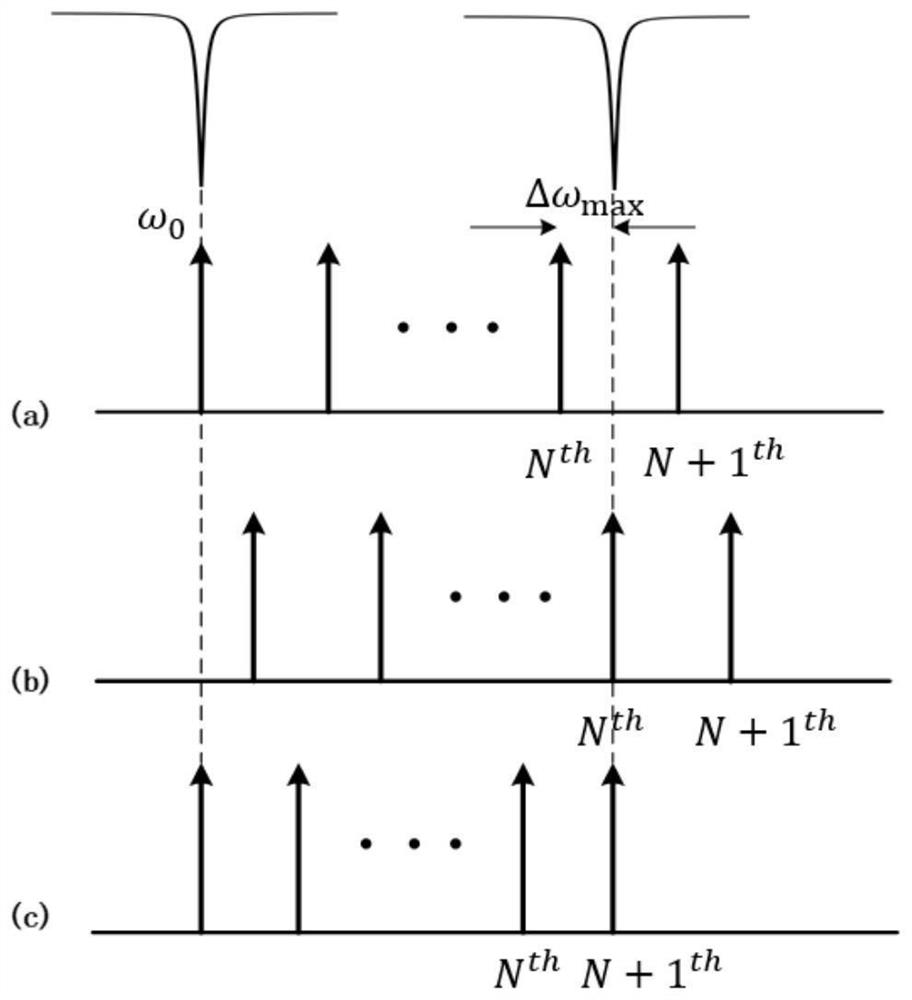

[0020] combine Figure 1 to Figure 4 , a strain measurement device based on super large measurement range PDH sensing, comprising a phase modulation module 12, a fiber grating sensing module 13 and a demodulation module 14, and a cyclic frequency shifting module 11, the narrow linewidth laser 101 passes through the first polarization The state controller 102 is sequentially connected with the cyclic frequency shifting module 11, the phase modulation module 12, and the fiber grating sensing module 13. The fiber grating sensing module 13 is connected with the demodulation module 14 through the photodetector 103, and the control in the demodulation module 14 The computer 143 and the quadrature demodulation module 141 are respectively connected to the cyclic frequency shifting module 11 and the phase modulation module 12; in the cyclic freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com