Novel wooden floor and manufacturing method thereof

A manufacturing method and wood technology, applied in the direction of manufacturing tools, wood layered products, and the joining of wooden veneers, can solve the problems of increased manufacturing costs, non-ideal surface flatness and mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

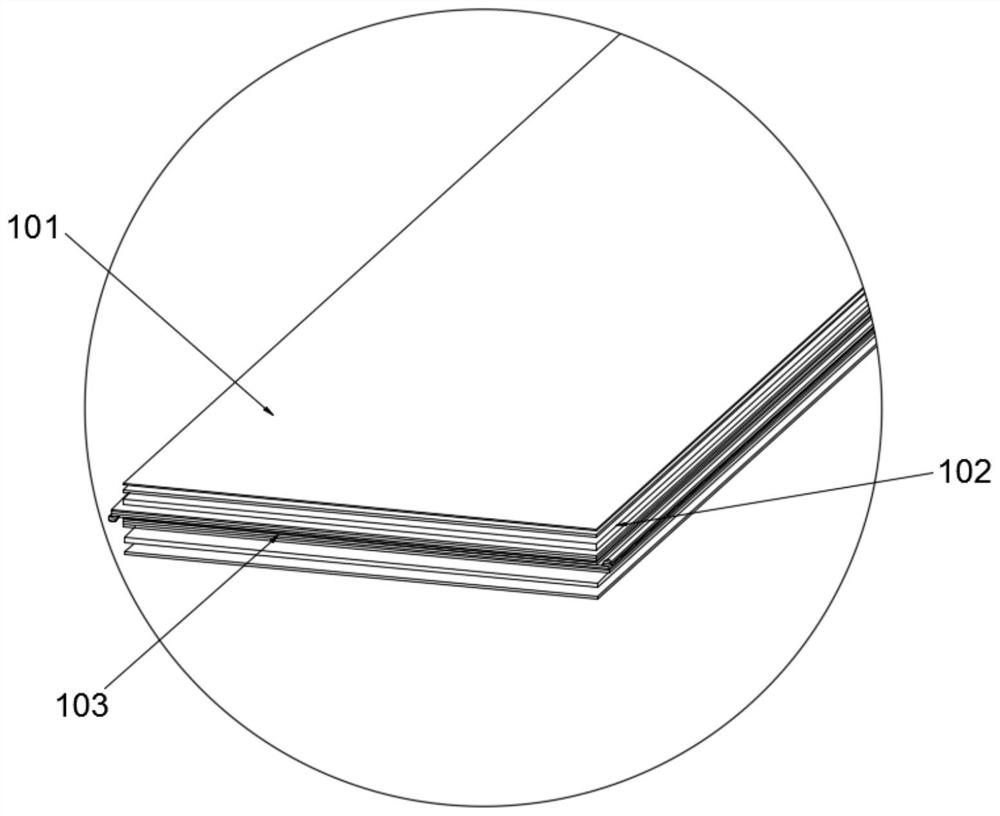

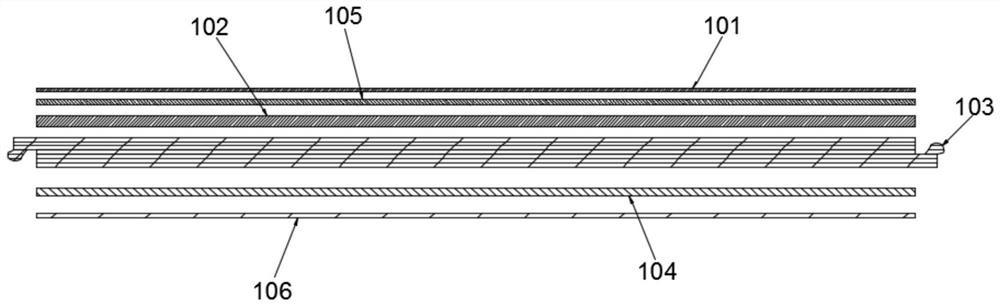

[0038] Example: Reference figure 1 , figure 2 A new type of wooden floor is shown, and its thickness direction includes a surface layer 101, a first strength layer 102, and a base material layer 103 sequentially from top to bottom, and the surface layer 101, the first strength layer 102, and the base material layer 103 are mutually Adhesive compound. Among them, the surface layer 101 is oak sliced veneer with a material thickness of 0.6 mm; the first strength layer 102 is a high-density fiberboard with a material density of 0.8 to 1.2 g / cm 3 (preferably 1.0g / cm 3 ), the material thickness is 0.5-3.0 mm (preferably 1.0 mm); the substrate layer 103 is a multi-layer composite board, the number of layers is 7 layers, and the thickness is 1.2 mm.

[0039] Since the density is higher than 1.0g / cm 3 The high-density fiberboard has a very smooth surface, so its surface contact angle is relatively small, which affects the adhesive bonding strength between it and the surface laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Material density | aaaaa | aaaaa |

| Material density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com