Sulfur-iron self-oxidation denitrification device and reaction control method

A technology of sulfur self-oxygen denitrification tank and denitrification, which is applied in chemical instruments and methods, anaerobic digestion treatment, biological treatment devices, etc. Good sealing, not easy to unload, reliable opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

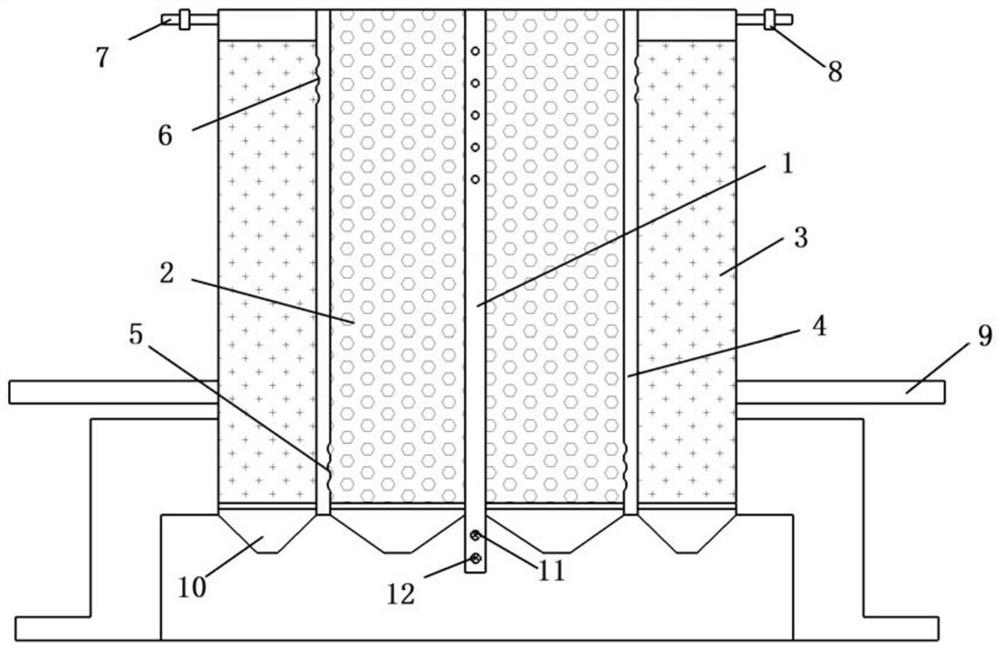

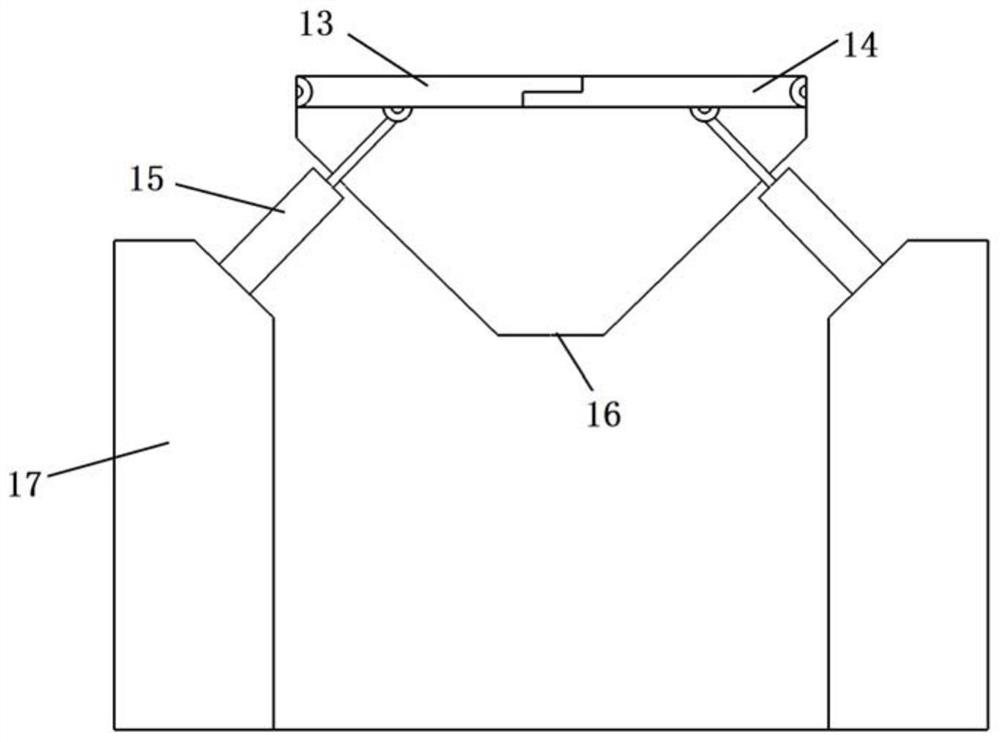

[0047] Figure 1 ~ Figure 2A specific embodiment of the present invention is shown, a sulfur iron aerobic denitrification device, comprising an iron aerobic denitrification bin 2 and a sulfur aerobic denitrification bin 3; the iron aerobic denitrification bin 2 is provided with a The water device is connected between the iron self-oxygen denitrification chamber 2 and the sulfur self-oxygen denitrification chamber 3; the top of the sulfur self-oxygen denitrification chamber 3 is provided with an air outlet pipe 7; the air outlet pipe 7 is provided with a gas concentration sensor , a gas flow sensor 8, a signal collector and a signal transmitter; the lower part of the sulfur auto-oxygen denitrification chamber 3 is provided with an outlet pipe 9; the signal transmitter transmits gas data information to the control platform.

[0048] The iron oxygen denitrification chamber and the sulfur oxygen denitrification chamber are independently designed, so that the reaction occurs indepe...

Embodiment 2

[0066] A method for controlling the reaction of a sulfur-iron autooxygen denitrification device, comprising the following steps:

[0067] 1) Pass sewage into the first hollow plate, and the sewage flows into the iron self-oxygen denitrification chamber through the first outlet hole on the upper part;

[0068] 2) The denitrified liquid and the reaction gas pass through the water inlet hole at the bottom to the second water outlet hole at the top and flow into the sulfur oxygen denitrification chamber;

[0069] 3) After the reaction of the sulfur self-oxygen denitrification chamber, the liquid is discharged through the outlet pipe, and the reaction gas is discharged through the exhaust pipe at the top;

[0070] 4) The control platform receives the gas flow and gas concentration data, judges according to the gas data, if the gas concentration is greater than or equal to the threshold, and the gas flow is lower than the threshold, it is judged that the pipeline is blocked and need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com