Device and method for washing polyvinyl alcohol fibers with water at low temperature

A polyvinyl alcohol fiber, low-temperature technology, applied in the direction of artificial filament cleaning/drying, synthetic polymer artificial filament chemical post-treatment, etc., can solve the problems of increased production, difficult production, and decreased output rate, and achieve reduction Residue, reduction of water consumption, effect of reduction of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

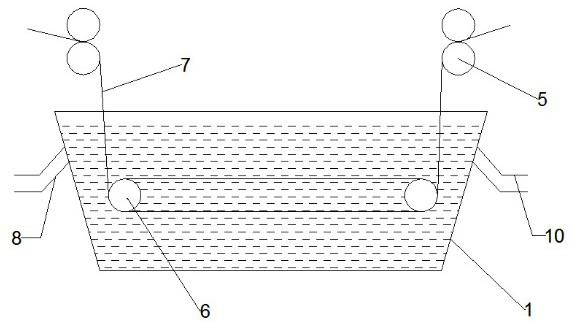

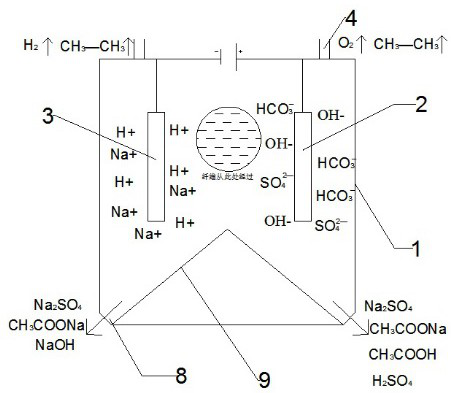

[0030] A device for washing polyvinyl alcohol fibers with low temperature water, comprising: an electrolytic cell 1, a positive electrode plate 2 arranged on both sides of the electrolytic cell 1, a negative electrode plate 3, and a polyvinyl alcohol fiber 7 passing through the positive electrode plate 2 and the negative electrode plate 3, the reaction waste outlet 8 arranged on both sides of the electrolytic cell 1, the gas outlet 4 arranged at the upper end of the electrolytic cell 1, and the polyvinyl alcohol fiber arranged at the position between the positive electrode plate 2 and the negative electrode plate 3 Transport components.

[0031] The polyvinyl alcohol fiber transmission component consists of: a squeeze roller 5 arranged at the front and back of the upper end of the electrolytic cell 1 , a guide roller 6 arranged in the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com