Vibration isolation and reduction support based on memory alloy

A technology of memory alloy and vibration isolation, which is applied to springs/shock absorbers, spring components composed of several springs, low internal friction springs, etc., and can solve the problems of structure failure, corrosion, and aging after vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

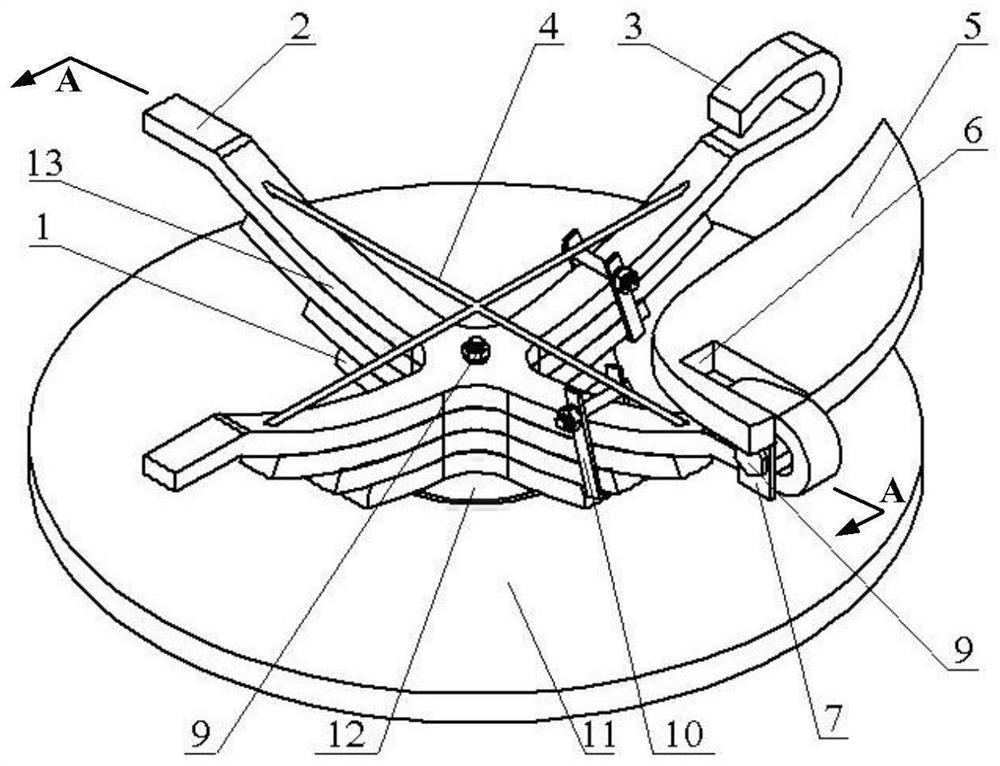

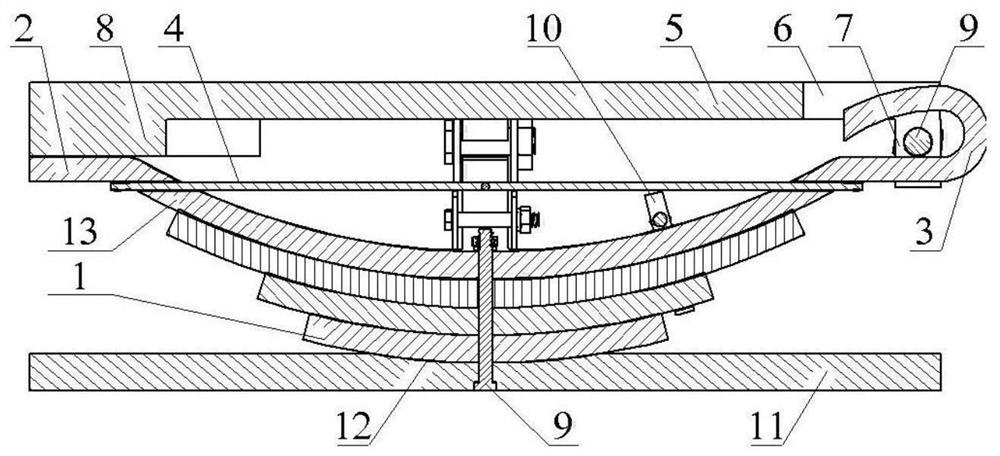

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

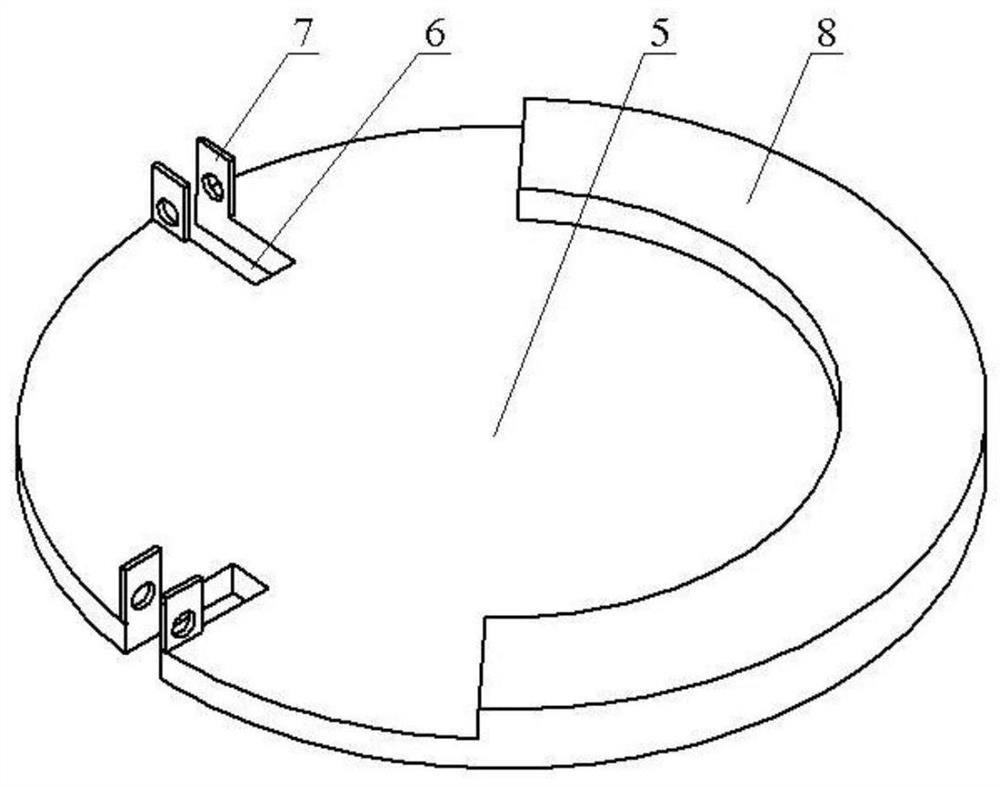

[0027] like Figure 1 to Figure 6 As shown, a memory alloy-based vibration-isolation and vibration-damping support includes a leaf spring group 1, an upper panel 5 and a lower panel 11;

[0028] The leaf spring group 1 is formed by stacking no less than one cross-shaped leaf spring 13, each leaf spring 13 has 4 spring arms, and the ends of the 4 spring arms of the uppermost leaf spring 13 are sequentially provided with 2 A lug 2 and two roll ears 3; the roll ear 3 is a curled bent plate; the leaf spring 13 is made of memory alloy; the middle part of each leaf spring 13 has a threaded through hole;

[0029] The lower panel 11 is a circular steel plate, the middle of which is provided with a spherical groove 12, the radius of curvature of the groove 12 is equal to the radius of curvature of the lower edge of the lowermost leaf spring 13; the lowermost leaf spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com