Precise drive brushless motor and driver circuit

A driver circuit, brushless motor technology, applied in the direction of motor, electronic commutator, electronic commutation motor control, etc., can solve problems such as performance deterioration, and achieve the effect of increasing power, increasing torque, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

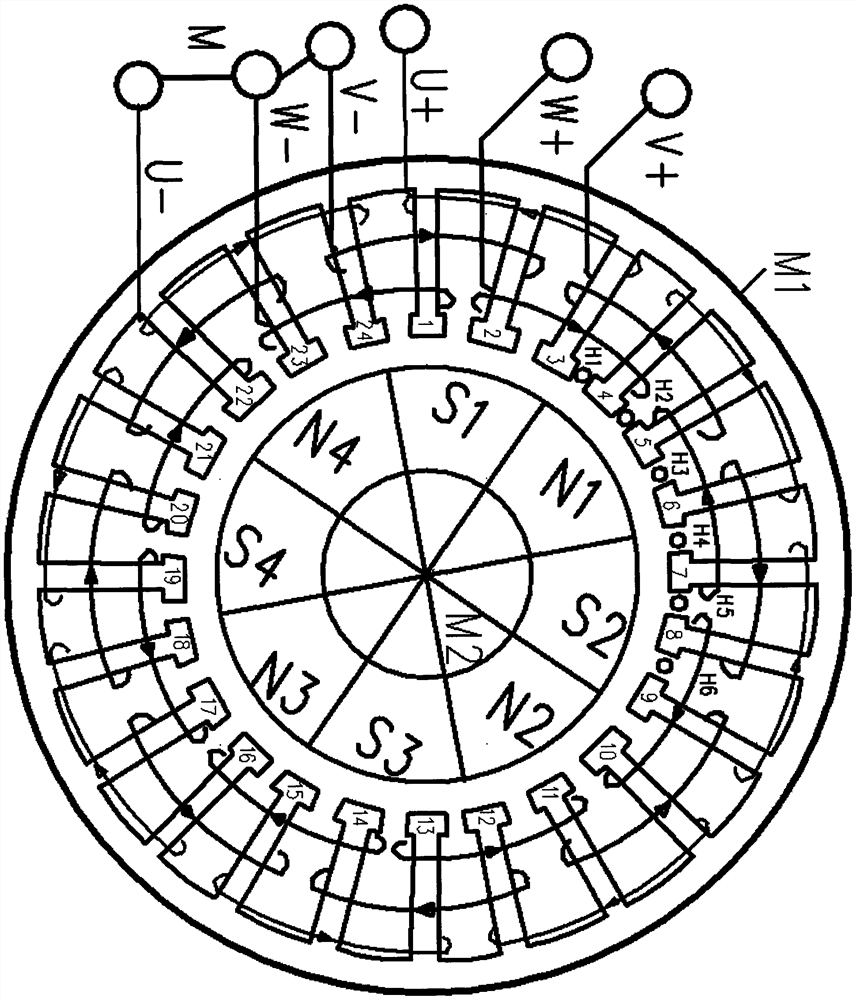

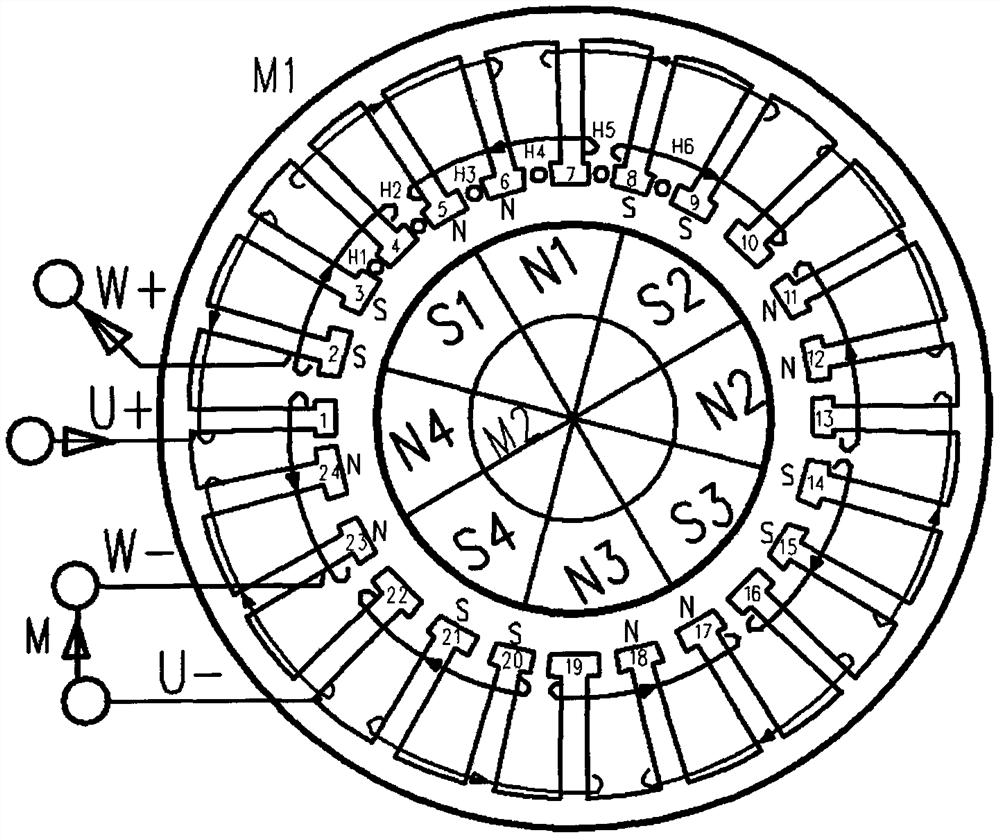

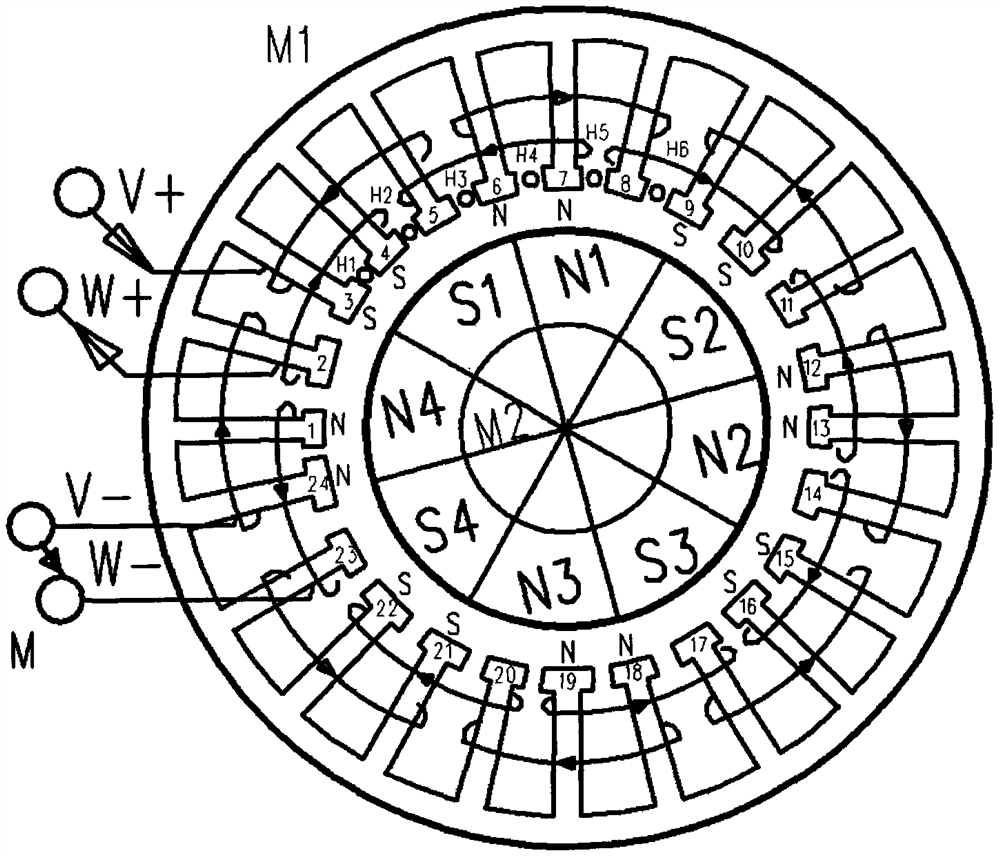

[0015] The invention provides precise drive brushless motor and its drive circuit, based on the principle of magnetic opposites attracting each other and same sex repelling each other, the position sensor is located in front of the driving coil in the brushless motor in the attraction rotation mode, after the position sensor gives a signal The driver energizes the phase coil in front of the position sensor to generate magnetic force to attract the rotor to the position of the phase coil, and then to the position of the next phase coil, thereby driving the rotor to rotate. In the repulsive force rotation mode, the position sensor is located behind the driving coil in the brushless motor. After the position sensor gives a signal, the driver energizes the phase coil behind the position sensor to generate magnetic force to repel the rotor to move away from the position of the phase coil. Then go to the coil position of the next phase, thereby driving the rotor to rotate. Drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com