Intelligent infusion system

A technology of transmission components and hanging baskets, which is applied in the fields of coating, medical science, and hospital equipment, etc., which can solve problems such as inability to optimize the infusion process, affect operational efficiency, and not be actually solved, so as to reduce walking time, optimize the infusion process, and facilitate The effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

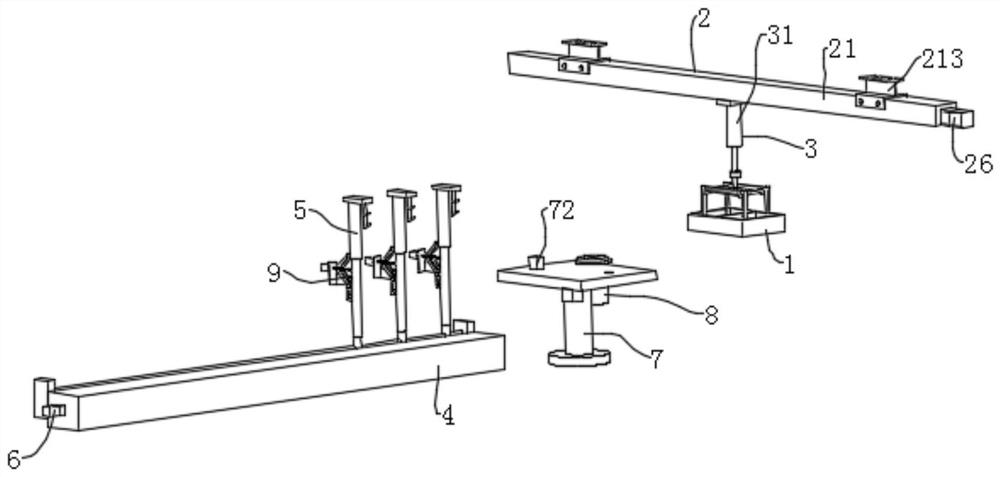

[0051] Such as figure 1 As shown, an intelligent infusion system mainly consists of the following parts, including:

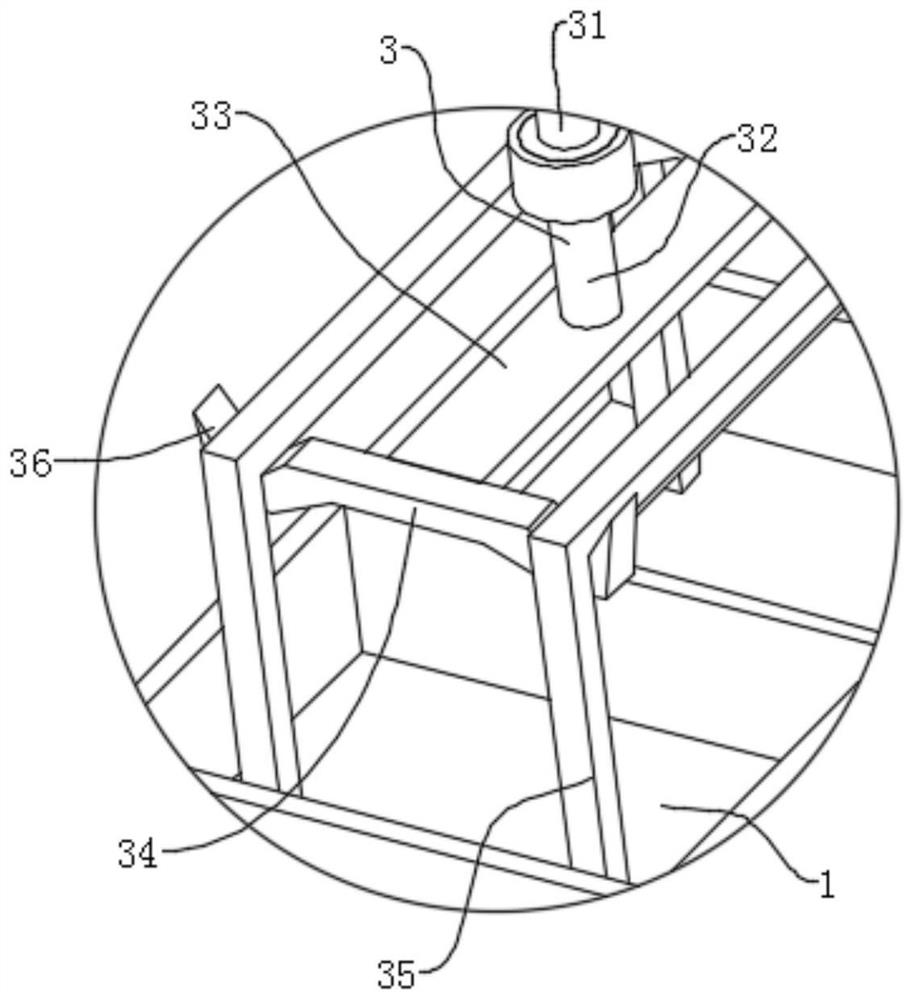

[0052] The hanging basket 1 for placing the medicine to be transfused, and the hanging basket 1 can be used for transporting the medicine;

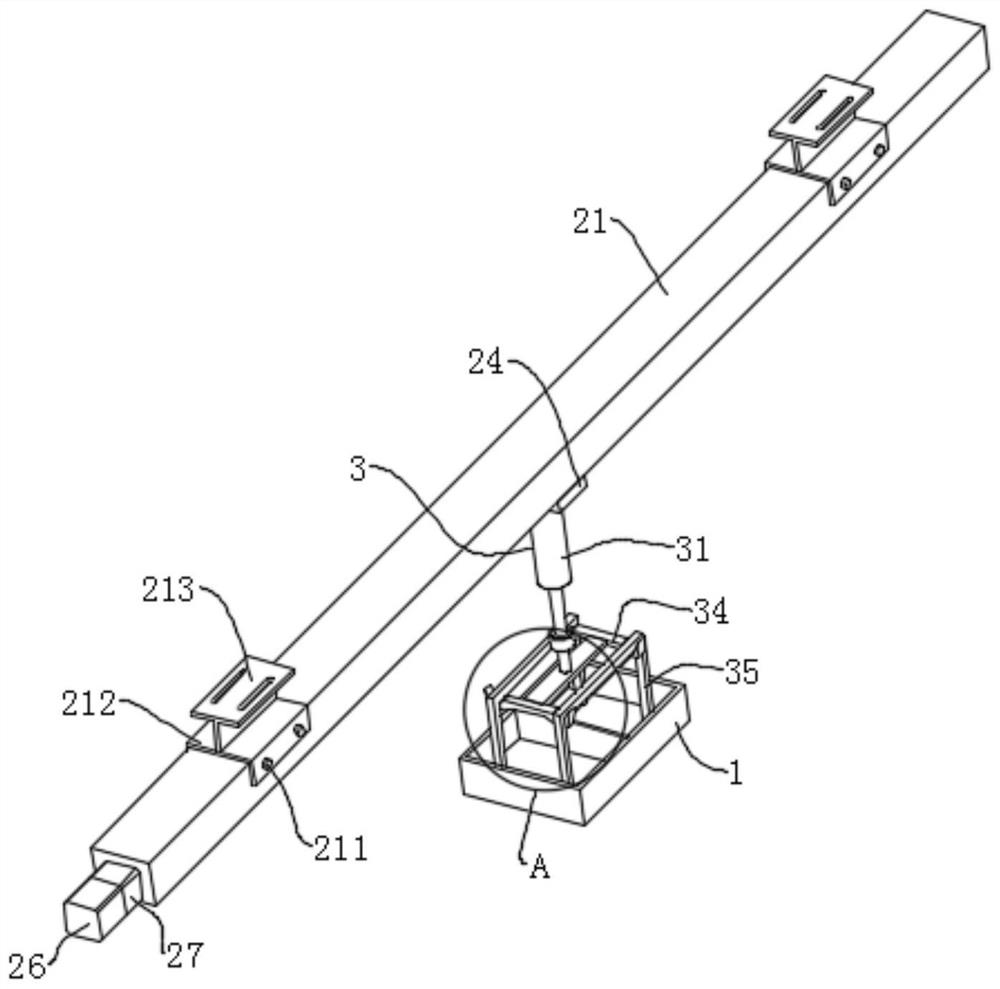

[0053] The transmission component 2 used to drive the hanging basket 1 to transfer from the pharmacy to the dispensing room and the infusion room;

[0054] The lifting adjustment component 3 used to drive the lifting and lowering of the hanging basket 1;

[0055] Seat plate 4 arranged in the infusion chamber;

[0056] Several groups of infusion components 5 that are slidingly connected to one side of the seat plate 4;

[0057] A drive assembly 6 for driving several sets of infusion assemblies 5 to slide;

[0058] The dispensing platform 7 set in the dispensing room;

[0059] And the garbage collection assembly 8 that is arranged on the dispensing platform 7 .

[0060] Such as figure 1 As shown, this intelligent infu...

Embodiment 2

[0072] The difference from Example 1 is that the surface of the dispensing platform 7 is coated with an antifouling coating, wherein the preparation process of the antifouling coating is as follows:

[0073] S1. Take the following ingredients by weight: 40 parts of polymethyl methacrylate, 20 parts of terephthalic acid, 30 parts of epoxy methyl ester, 20 parts of tetraalkoxysilane, 15 parts of calcium chloride, 15 parts of polyethylene glycol part, 10 parts of benzphenone, 10 parts of benzophenone, 5 parts of stabilizer;

[0074] S2. Mix polymethyl methacrylate, terephthalic acid, epoxy methyl ester, and tetraalkoxysilane evenly, stir and fully mix at a speed of 2500r / min, and plasticize at 281°C for 2 hours in an internal mixer;

[0075] S3, after the plasticization is completed, continue to add calcium chloride, polyethylene glycol, diphenyl ethyl ketone, and stabilizer;

[0076] S4. After the reaction is completed, take out the product, add benzophenone and mix evenly, and...

Embodiment 3

[0078] The difference from Example 2 is the preparation of antifouling coating, wherein the preparation process of antifouling coating is as follows:

[0079] S1. Take the following ingredients by weight: 50 parts of polymethyl methacrylate, 25 parts of terephthalic acid, 35 parts of epoxy methyl ester, 30 parts of tetraalkoxysilane, 20 parts of calcium chloride, 24 parts of polyethylene glycol part, 10 parts of benzphenone, 10 parts of benzophenone, 5 parts of stabilizer;

[0080] S2. Mix polymethyl methacrylate, terephthalic acid, epoxy methyl ester, and tetraalkoxysilane evenly, stir and fully mix at a speed of 2600r / min, and plasticize at 285°C for 2 hours in an internal mixer;

[0081] S3, after the plasticization is completed, continue to add calcium chloride, polyethylene glycol, diphenyl ethyl ketone, and stabilizer;

[0082] S4. After the reaction is completed, take out the product, add benzophenone and mix evenly, and perform thermal compounding for 1 hour to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com