Moving system of large-diameter thickener

A thickener and large-diameter technology, applied in chemical instruments and methods, separation methods, precipitation and separation, etc., can solve the problems of difficult concentration operations, no modular mobile facilities, etc., to save energy consumption, reduce transportation costs and road construction. cost, and the effect of reusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

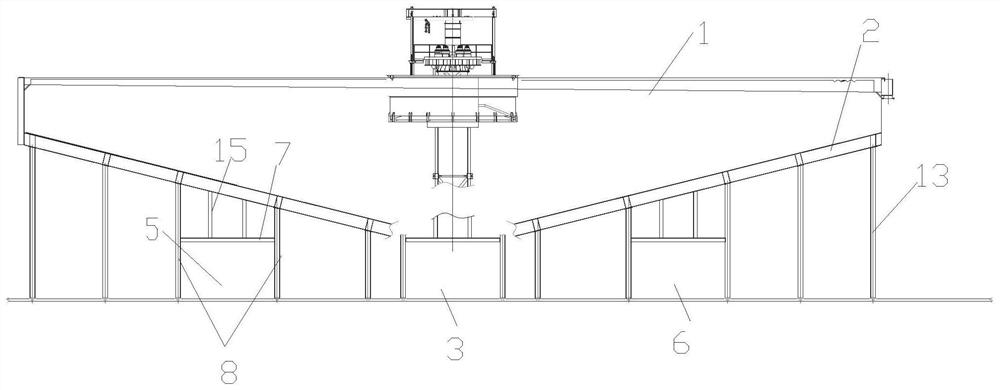

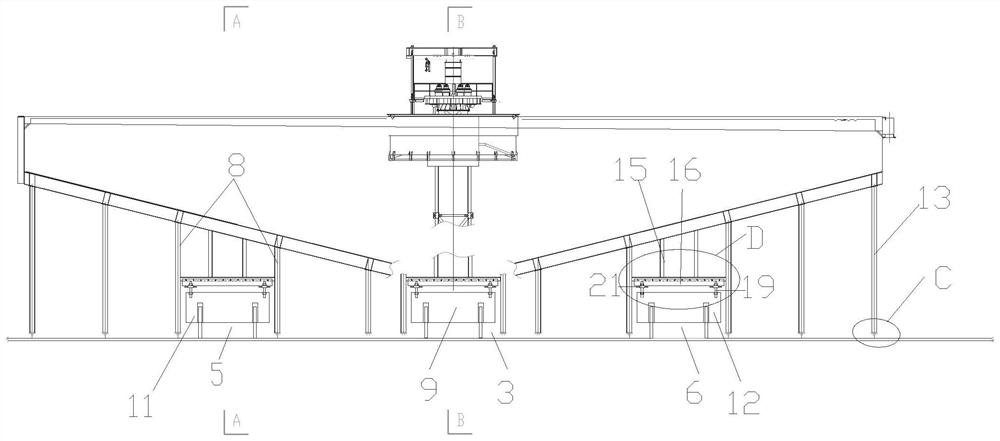

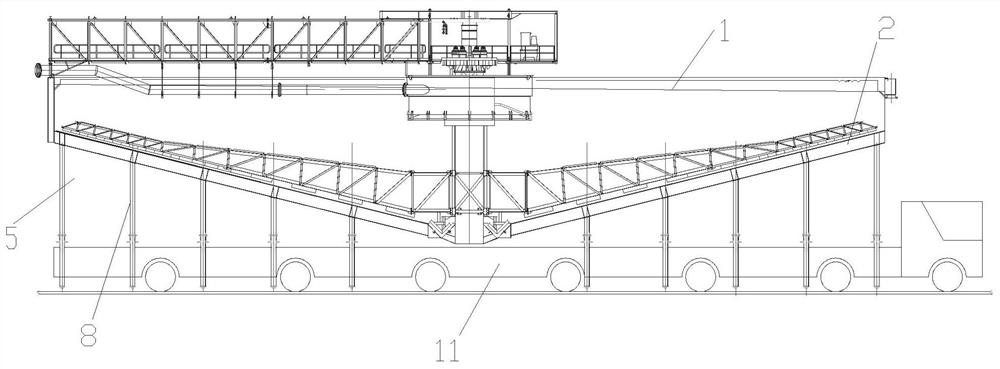

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the large-diameter concentrator transfer system proposed in this embodiment can be used for the elevated steel structure concentrator to be fixed on the ground and moved as a whole. The tank body 2 of the elevated steel structure concentrator is bucket-shaped or circular, and the lower part of the tank body 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com