Glue melting tank for health care product production and use method thereof

A technology for using chemical glue tanks and health products, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of inaccurate and timely judgment of tank bodies, unclear observation, etc., and achieve the convenience of observation work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

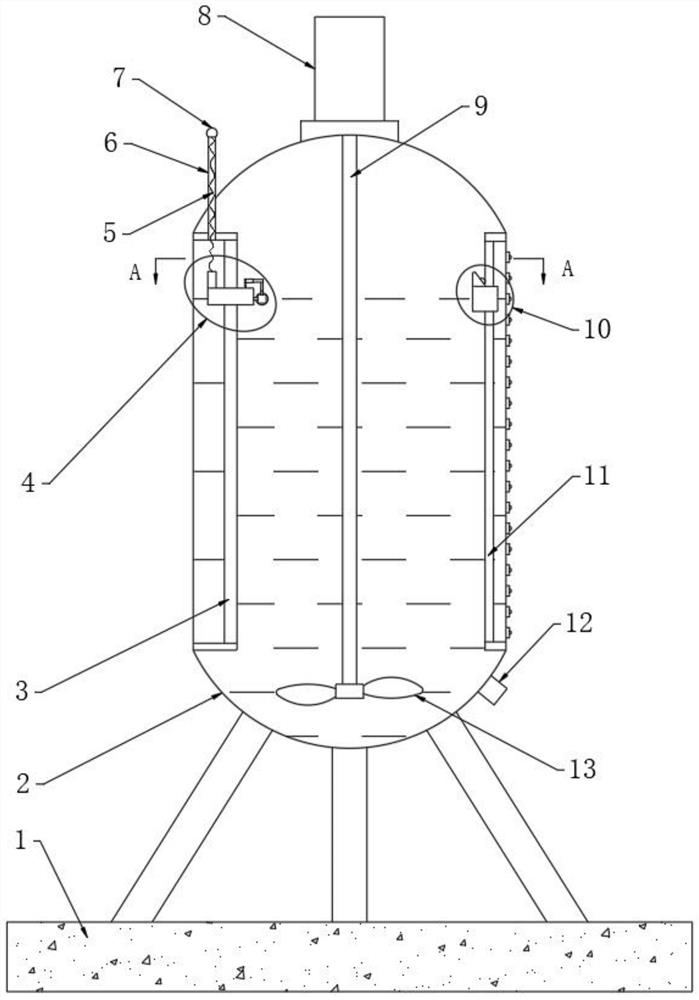

[0036] Such as Figure 1-6 As shown, this embodiment proposes a chemical glue tank for the production of health care products, including a tank body 2 arranged on the ground 1, and a stirring paddle 13 is rotatably connected to the inside of the tank body 2, and the stirring paddle 13 is connected to the tank body 2 by a Stirring motor 8 drives.

[0037] The stirring motor 8 is fixedly connected with the outer wall of the tank body 2, and the tank body 2 is connected with a transmission shaft 9 through bearing rotation, one end of the transmission shaft 9 passes through the tank body 2, and the part of the transmission shaft 9 passing through the tank body 2 is connected with the stirring motor 8. The other end of the shaft 9 is fixedly connected with the stirring paddle 13; the tank body 2 is also provided with a glue outlet 12 and a material inlet.

[0038] Wherein, the stirring paddle 13 is designed in the shape of a fan blade to facilitate the stirring work of the liquid....

Embodiment 2

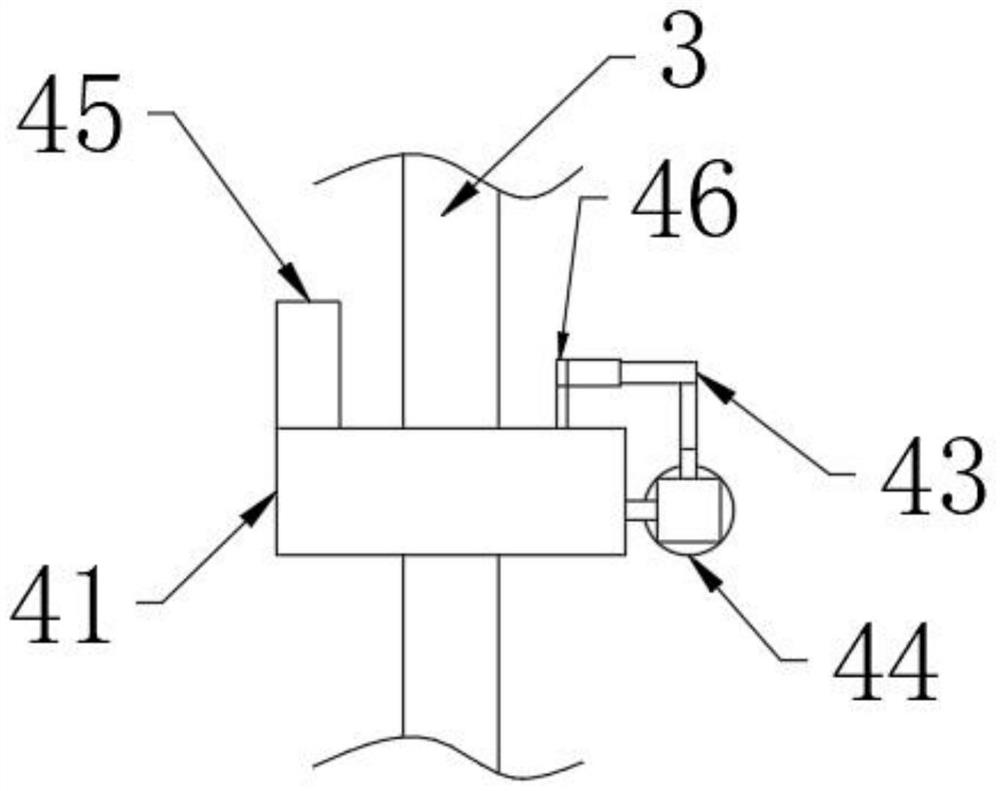

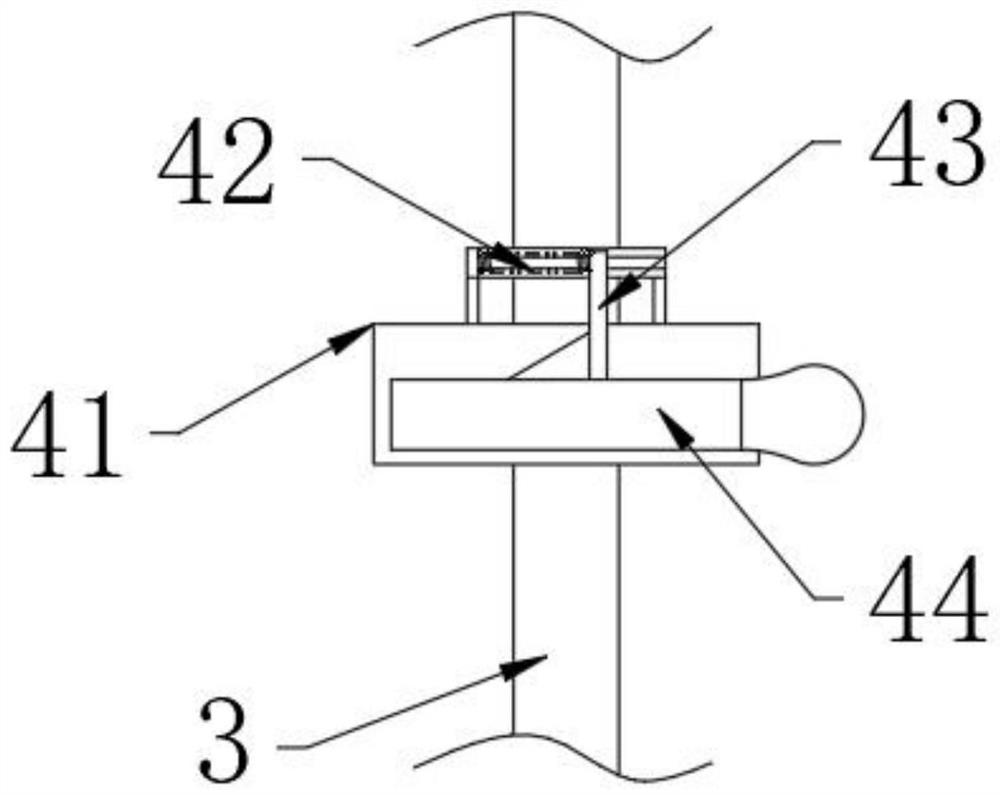

[0051] Reference attached Figure 1-6 , the other structures are the same as the first embodiment, the difference is that when there is residual liquid in the tank body 2, the float 101 always cooperates with the sensor 103, which is not conducive to the detection work and affects the detection accuracy.

[0052] Therefore, a chute is provided in the float 101, and the diameter of the chute is larger than that of the second guide post 11. The float 101 is sleeved on the second guide post 11 through the chute, and the upper end of the float 101 is also fixedly connected with a shrapnel 102. It is arranged on one side of the second guide column 11.

[0053] Under the action of the shrapnel 102, in the initial state, the shrapnel 102 is in contact with the second guide post 11, so that the float 101 moves to the left relative to the second guide post 11. At this time, the float 101 is separated from the inductor 103, and the inductor 103 The signal from the float 101 is not dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com