Safe storage device for chemical new material

A storage device and new material technology, applied in the direction of unloading device, packaging, transportation and packaging, etc., can solve the problems of inconvenient ventilation, inconvenient observation, inconvenient sampling and testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

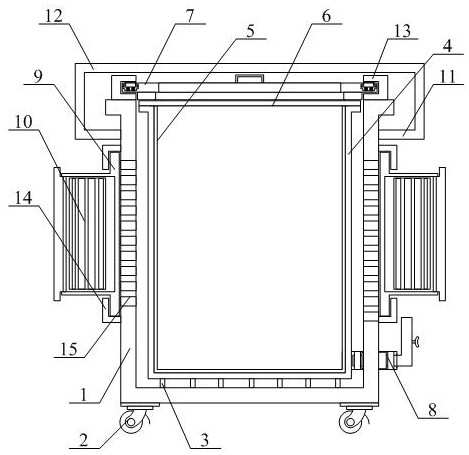

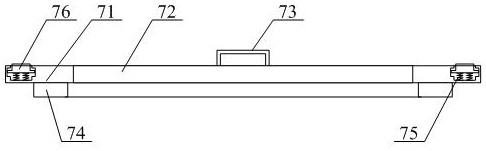

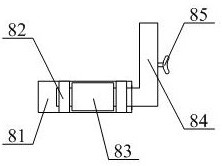

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a safe storage device for new chemical materials includes a storage shell 1, a movable brake wheel 2, a support rod 3, a storage inner barrel 4, a moisture-proof layer 5, a rubber ring 6, and a top-tight cover structure 7 that can be plugged in for observation and can be rotated. Sealed sampling tube structure 8, plug-in and detachable ventilation tube structure 9, moisture-removing plug-in tube structure 10, rotating rod 11, inverted U-shaped lifting rod 12, U-shaped fixing seat 13, L-shaped fixing seat 14 and ventilation hole 15, The moving brake wheels 2 are respectively bolted to the four corners of the lower end of the storage case 1; the lower ends of the support rods 3 are bolted to the inner bottom of the storage case 1 from left to right; The upper end is bolted to the lower end of the storage inner barrel 4 in turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com