Welding device and welding method for bead-shaped thermistor and wire

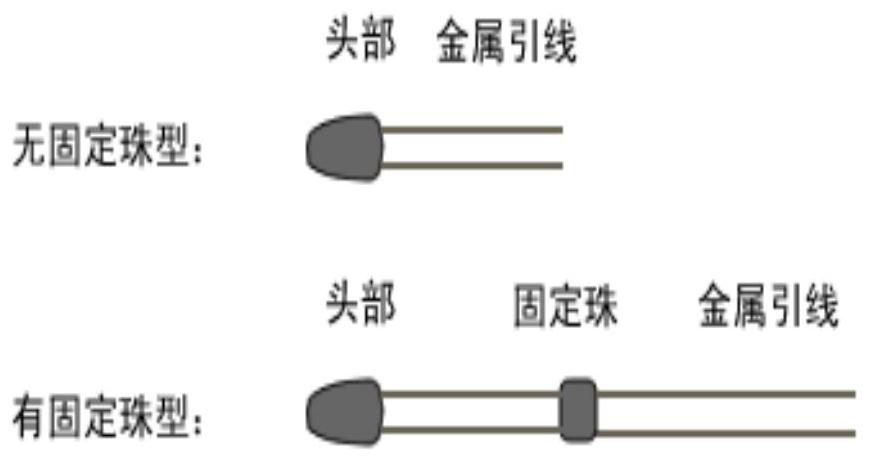

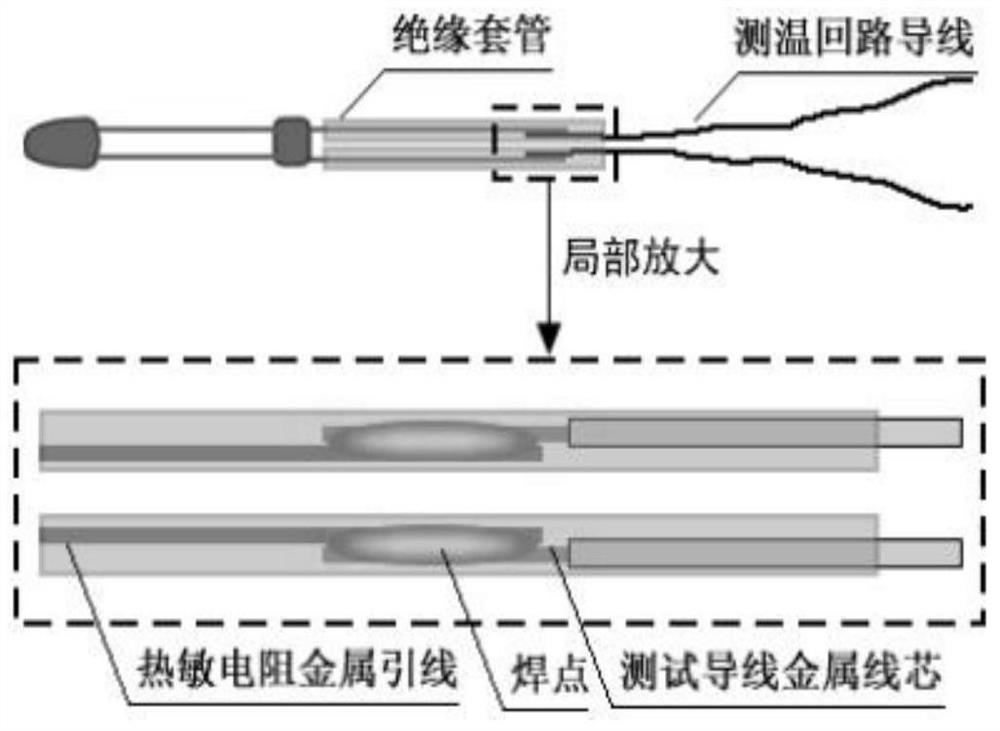

A thermistor and welding device technology, applied in auxiliary devices, welding equipment, metal processing, etc., can solve the problems of easy passivation of the nickel-plated protective layer, difficult operation, and overall damage to the head surface, so as to improve the unit Improve the welding success rate and production efficiency, reduce the difficulty of operation, and reduce the effect of welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

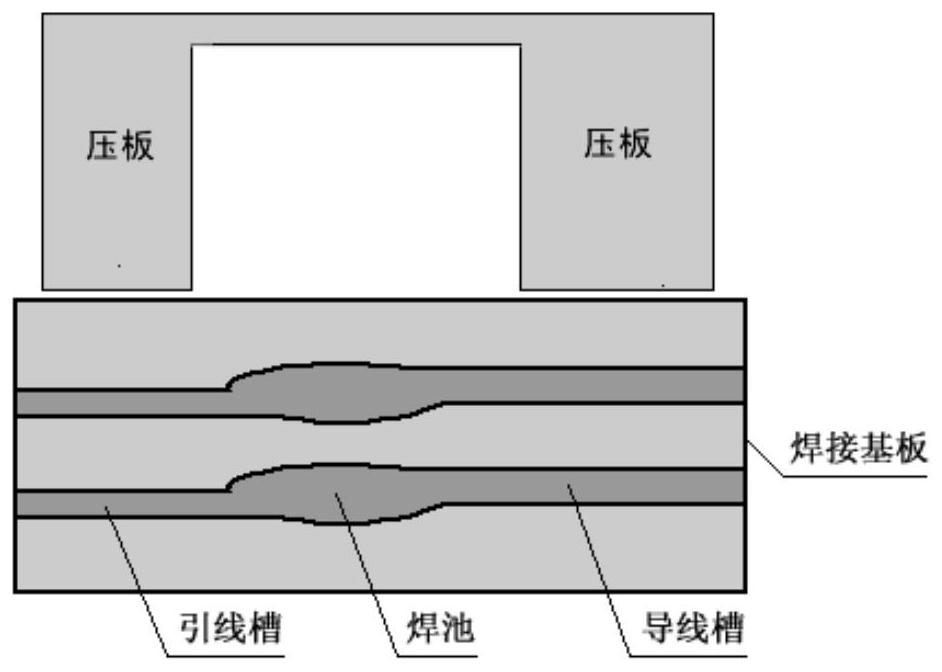

[0035] The first embodiment of the present invention discloses a bead thermistor and a wire welding device, such as image 3 shown, including: soldered base plate and pressure plate, wherein,

[0036] The top surface of the soldering substrate is a plane, and there are 3 grooves connected with each other and the center lines are on the same horizontal plane;

[0037] The pressing plate is used to fix the wires and leads filled in the grooves.

[0038] The centerline of the wireway and wireway needs to have a little horizontal distance so that they just touch to reduce the size of the solder joint.

[0039] In a specific embodiment, the three grooves that communicate with each other are a lead groove, a lead groove and a solder pool, the lead groove is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com