Interface inclusion reinforced thermoplastic composite material ultrasonic welding method

A technology of ultrasonic welding and composite materials, which is applied in the field of ultrasonic welding of thermoplastic composite materials reinforced by interfacial inclusions, can solve the problems of low peel strength, low tensile/peel strength, and low strength of resin matrix, and achieve improved peel strength, Effect of improving tensile/peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

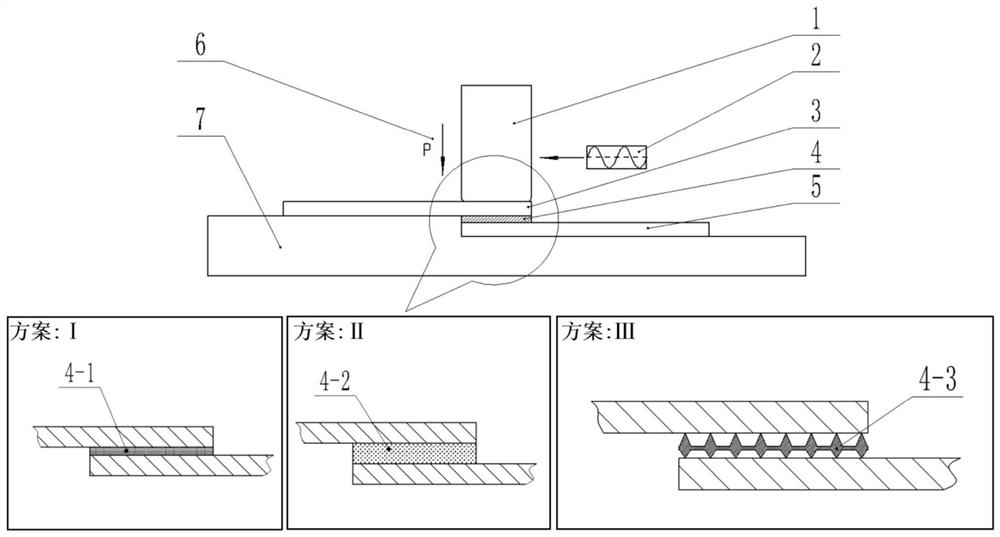

[0080] 1) Prepare the second fiber-reinforced thermoplastic composite material plate 3 and the first fiber-reinforced thermoplastic composite material plate 5 whose dimensions are 101.6 mm in length, 25.4 mm in width and 2 mm in thickness;

[0081] 2) adding carbon nanotubes or graphene into the ethanol solution for ultrasonic stirring, and making 5ml of a suspension with a concentration of 5mg / mL;

[0082] 3) Apply the suspension prepared in the above 2) evenly on the area to be welded of the first fiber reinforced thermoplastic composite material plate 5, and perform drying treatment at a temperature of 60° C. for 10 minutes to obtain carbon nanotubes or Graphene interfacial inclusion zone 4-1;

[0083] 4) Place the carbon nanotube or graphene interfacial inclusion region 4-1 obtained on the first fiber-reinforced thermoplastic composite material plate 5 treated above facing up and directly below the ultrasonic welding head 1, and fix it on the welding anvil 7 ;

[0084] (...

Embodiment 2

[0092] 1) Prepare the second fiber-reinforced thermoplastic composite material plate 3 and the first fiber-reinforced thermoplastic composite material plate 5 whose dimensions are 101.6 mm in length, 25.4 mm in width and 2 mm in thickness;

[0093] 2) adding carbon nanotubes or graphene into the ethanol solution for ultrasonic stirring, and making 5ml of a suspension with a concentration of 5mg / mL;

[0094] 3) Apply the suspension prepared in the above 2) evenly on the area to be welded of the first fiber reinforced thermoplastic composite material plate 5, and perform drying treatment at a temperature of 60° C. for 10 minutes to obtain carbon nanotubes or Graphene interfacial inclusion zone 4-1;

[0095] 4) Place the carbon nanotube or graphene interfacial inclusion region 4-1 obtained on the first fiber-reinforced thermoplastic composite material plate 5 treated above facing up and directly below the ultrasonic welding head 1, and fix it on the welding anvil 7 ;

[0096] (...

Embodiment 3

[0103] 1) Prepare the second fiber-reinforced thermoplastic composite material plate 3 and the first fiber-reinforced thermoplastic composite material plate 5 whose dimensions are 101.6 mm in length, 25.4 mm in width and 2 mm in thickness;

[0104] 2) adding carbon nanotubes or graphene into the ethanol solution for ultrasonic stirring, and making 5ml of a suspension with a concentration of 30mg / mL;

[0105] 3) Apply the suspension prepared in the above 2) evenly on the area to be welded of the first fiber reinforced thermoplastic composite material plate 5, and perform drying treatment at a temperature of 60° C. for 10 minutes to obtain carbon nanotubes or Graphene interfacial inclusion zone 4-1;

[0106] 4) Place the carbon nanotube or graphene interfacial inclusion region 4-1 obtained on the first fiber-reinforced thermoplastic composite material plate 5 treated above facing up and directly below the ultrasonic welding head 1, and fix it on the welding anvil 7 ;

[0107] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com