Magnesium alloy plate with low rare earth content and high fatigue performance and preparation method thereof

A fatigue performance, magnesium alloy technology, applied in the field of rare earth-containing magnesium alloys, can solve the problems of poor plastic deformation ability, easy formation of coarse grains, etc., to improve fatigue performance, increase the tendency of basal plane slip, and improve the yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

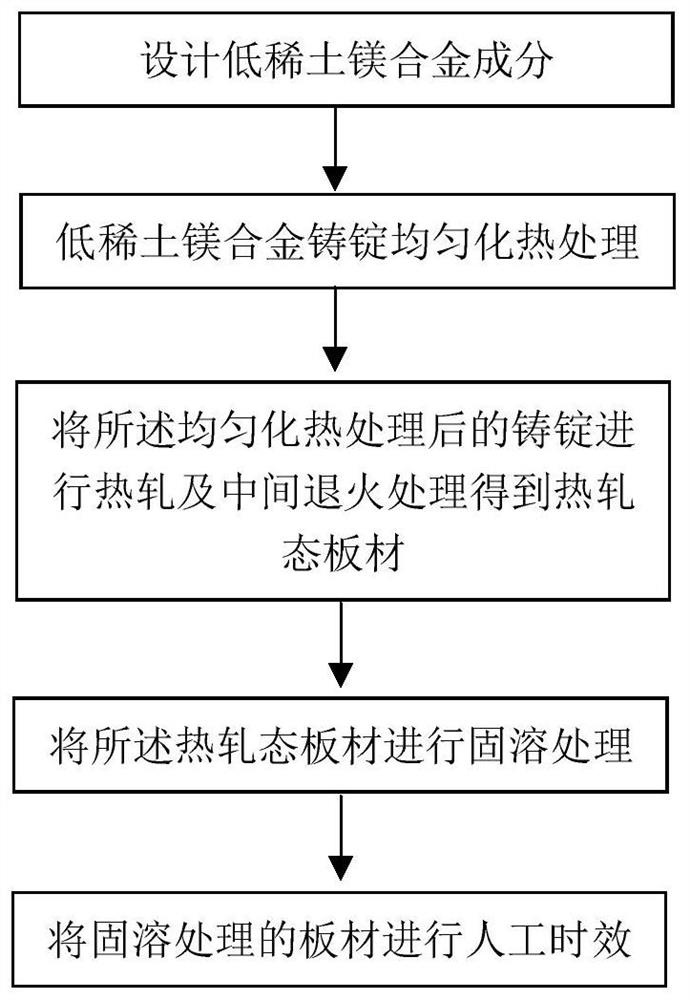

Method used

Image

Examples

Embodiment 1

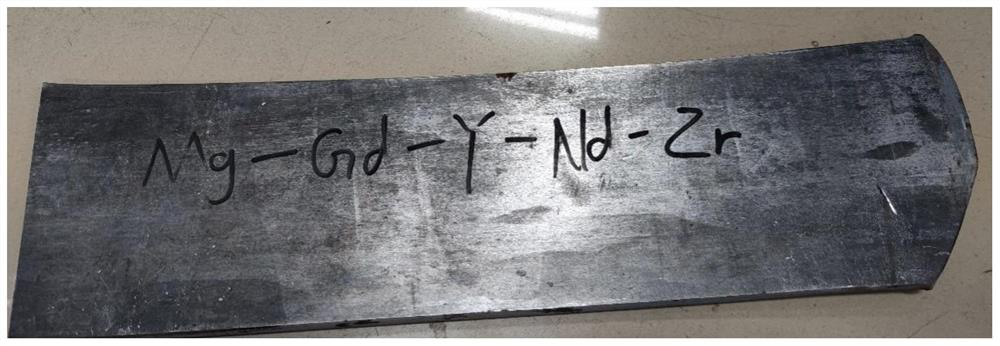

[0043] This embodiment provides a low rare earth magnesium alloy and a preparation method thereof. The preparation method of the low rare earth magnesium alloy comprises the following steps:

[0044] S1: Put pure Mg ingot and Mg-30wt.%Gd, Mg-25wt.%Y, Mg-30wt.%Nd, Mg-30wt.%Zr master alloy into the melting furnace, preheat the master alloy before melting to remove Moisture in the raw material, grinding to remove the scale in the raw material. Melting and casting low-rare-earth magnesium alloy flat ingot with alloy composition of Mg-5Gd-2Y-1.0Nd-0.5Zr, the melting process is protected by argon, and the size of the flat ingot is 500mm*300mm*50mm;

[0045] S2: Machining the rare earth magnesium alloy flat ingot obtained by smelting and casting to remove surface scale and inclusions, the size of the flat ingot after machining is 480mm*280mm*45mm;

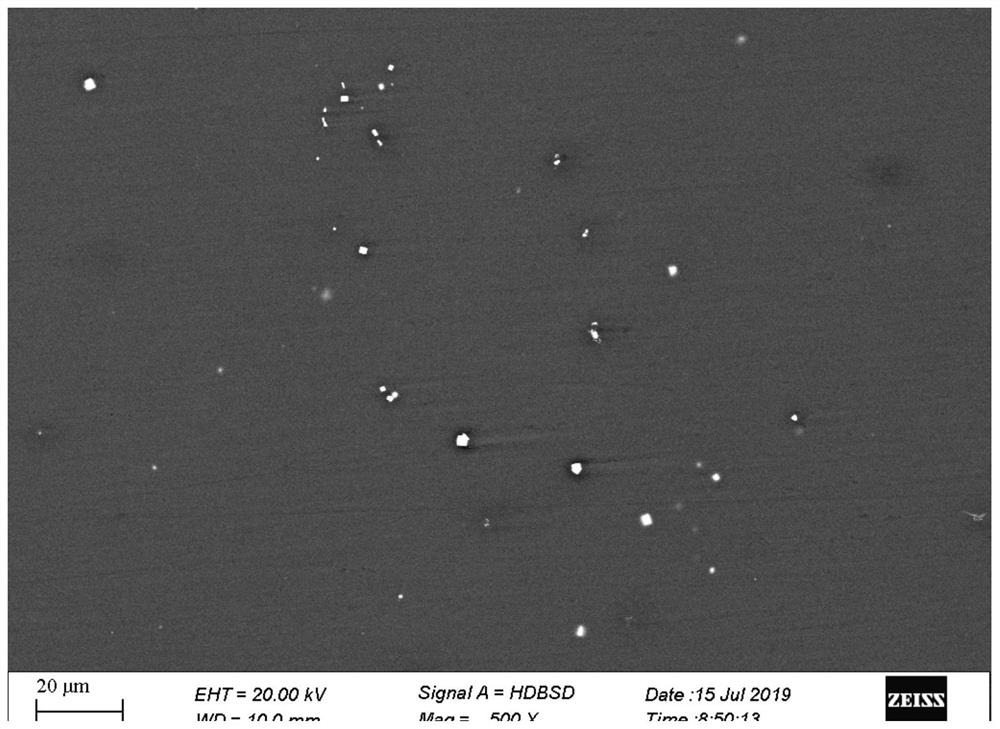

[0046] S3: placing the machined rare earth magnesium alloy flat ingot in an argon-protected holding furnace for uniform heat treatment...

Embodiment 2

[0060] This embodiment provides a low rare earth magnesium alloy and a preparation method thereof. The preparation method of the low rare earth magnesium alloy comprises the following steps:

[0061] S1: Put pure Mg ingot and Mg-30wt.%Gd, Mg-25wt.%Y, Mg-30wt.%Nd, Mg-30wt.%Zr master alloy into the melting furnace, preheat the master alloy before melting to remove Moisture in the raw material, grinding to remove the scale in the raw material. Melting and casting low-rare-earth magnesium alloy flat ingot with alloy composition of Mg-6Gd-2Y-1.0Nd-0.5Zr, the melting process is protected by argon gas, and the size of the flat ingot is 500mm*300mm*50mm;

[0062] S2: Machining the rare earth magnesium alloy flat ingot obtained by smelting and casting to remove surface scale and inclusions, the size of the flat ingot after machining is 480mm*280mm*45mm;

[0063] S3: placing the machined rare earth magnesium alloy flat ingot in an argon-protected holding furnace for uniform heat treat...

Embodiment 3

[0078] This embodiment provides a low rare earth magnesium alloy and a preparation method thereof. The preparation method of the low rare earth magnesium alloy comprises the following steps:

[0079] S1: Put pure Mg ingot and Mg-30wt.%Gd, Mg-25wt.%Y, Mg-30wt.%Nd, Mg-30wt.%Zr master alloy into the melting furnace, preheat the master alloy before melting to remove Moisture in the raw material, grinding to remove the scale in the raw material. Melting and casting low-rare-earth magnesium alloy flat ingot with alloy composition of Mg-6.6Gd-3.2Y-1.0Nd-0.5Zr. The melting process is protected by argon gas. The size of the flat ingot is 500mm*300mm*50mm;

[0080] S2: Machining the rare earth magnesium alloy flat ingot obtained by smelting and casting to remove surface scale and inclusions, the size of the flat ingot after machining is 480mm*280mm*45mm;

[0081] S3: placing the machined rare earth magnesium alloy flat ingot in an argon-protected holding furnace for uniform heat treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com