Titanium microalloyed high strength steel, preparation method and application thereof

A technology of micro-alloying and high-strength steel, which is applied in the field of solidification structure refinement of high-strength steel, and can solve problems such as coarse grains of high-strength steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

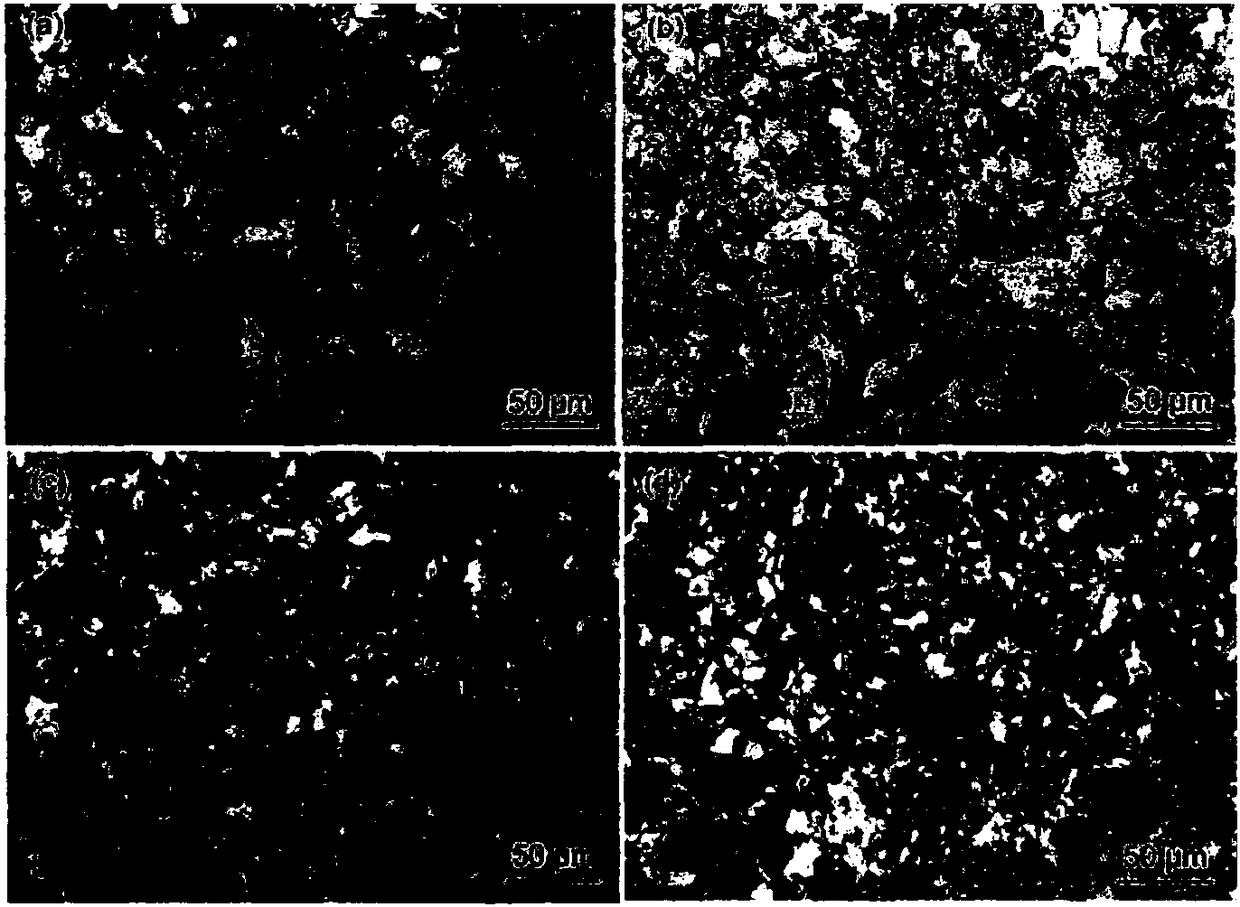

Image

Examples

preparation example Construction

[0031] The preparation method of the titanium microalloyed high-strength steel comprises the following steps:

[0032] (1) mixing SAPH440 steel grade and pure iron for vacuum melting to obtain molten steel;

[0033] (2) refining the molten steel obtained in the step (1) to obtain refined molten steel;

[0034] (3) Add ferrosilicon, ferroniobium and metal manganese successively to the molten steel obtained in the step (2) for smelting, then add aluminum grains for deoxidation, and after deoxidation, add ferro-titanium alloy for alloying to obtain alloyed steel liquid;

[0035] (4) Cooling the molten alloyed steel obtained in the step (3) to obtain titanium microalloyed high-strength steel, and the cooling includes furnace cooling and pulse magnetic shock treatment.

[0036] In the titanium micro-alloyed high-strength steel provided by the present invention, the smaller TiC can be dispersed and precipitated in the iron matrix, which can produce a strong precipitation strengthe...

Embodiment 1

[0059] The titanium microalloyed high-strength steel prepared in this embodiment includes the following components in weight percentage according to the elemental composition:

[0060] 0.035% C, 0.1% Si, 1.46% Mn, 0.021% Nb, 0.112% Ti, the balance Fe.

[0061] The prepared steel raw material (steel type is SAPH440) is pretreated, and the pure iron block is removed with an angle grinder to remove scale. SAPH440 is dried and preheated in a heating furnace at a temperature of 500°C for 1 hour. It is then placed in a preconditioned vacuum induction furnace. Melting begins, and molten steel is obtained. The setting parameters and melting parameters in the pretreatment furnace are as follows:

[0062] Vacuum up to 20Pa before melting, start power transmission, power transmission power is 25kW, power supply is about 25min, and heat the furnace; when the power reaches 65kW during melting, power supply is 40min, and then the power continues to rise to 85kW, keep the power unchanged, ...

Embodiment 2

[0067] The titanium microalloyed high-strength steel prepared in this embodiment includes the following components in weight percentage according to the elemental composition:

[0068] 0.040% C, 0.12% Si, 1.50% Mn, 0.024% Nb, 0.115% Ti, the balance Fe.

[0069] The preparation method of this embodiment is basically the same as that of Example 1, the difference being that the process parameters of the magneto-oscillation treatment are:

[0070] The range of pulse frequency f is 2000Hz, the pulse voltage U is 5000V, and the peak value of pulse current I is 10 4 a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com