Batch hot-dip efficient environment-friendly continuous plating process and equipment

A hot-dip and process technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of difficult to achieve continuous high-efficiency production, long waiting time for batch hot-dip plating, low work efficiency, etc. Shorten working time, reduce waiting time, and produce efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

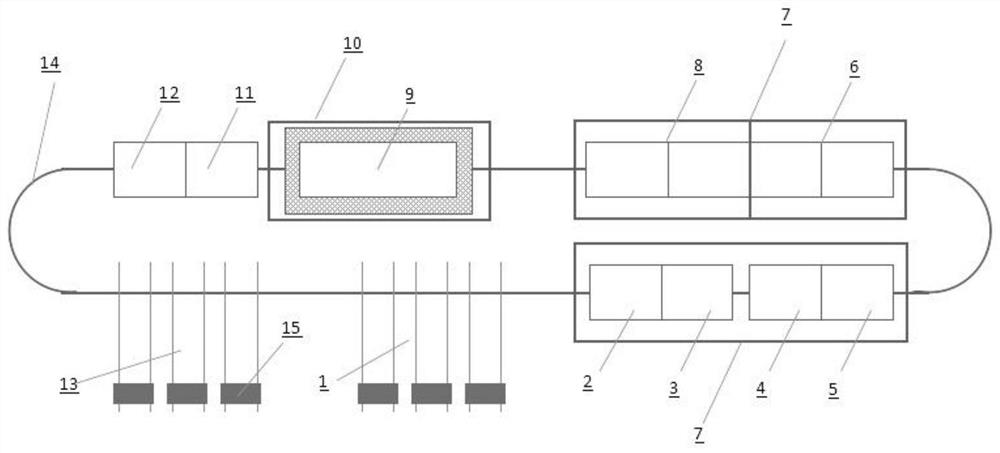

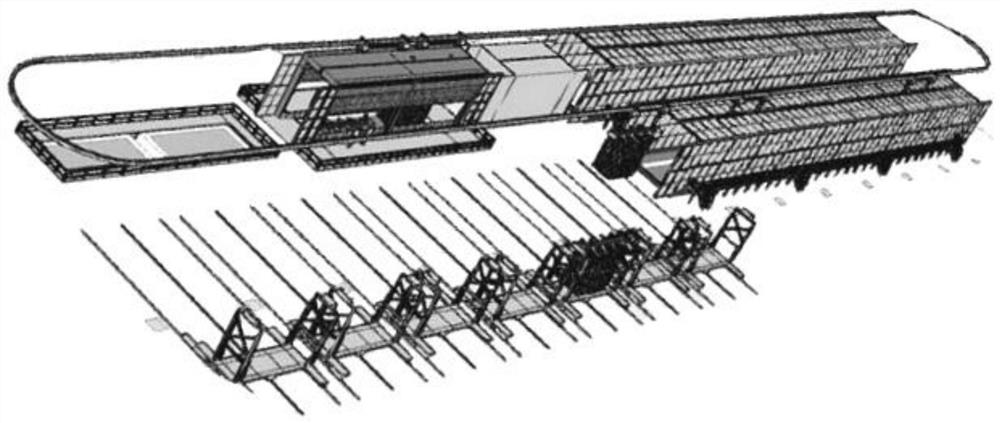

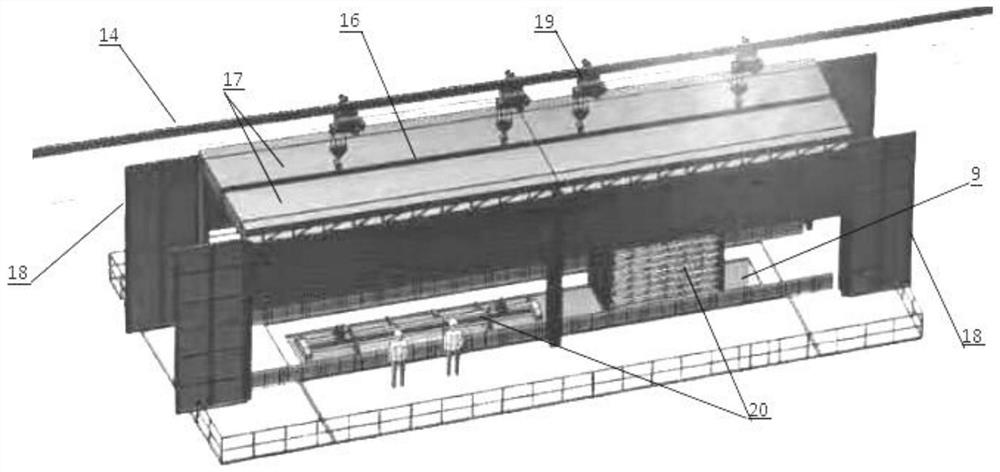

[0042] The product to be hot-plated in this embodiment is scaffolding for construction, and its grade is Q235 (chemical composition: C0.14-0.22% Mn0.30-0.65% Si≤0.30%S≤0.050P≤0.045).

[0043] Before the present invention was made, the crane linear reciprocating plating process was usually used for batch galvanizing of structural parts; it was necessary to unload the workpiece after galvanizing in the pre-treatment process, and then the crane returned to the starting area to load the next batch The hot-dip plating; and the scaffold uses inorganic acids such as hydrochloric acid for pickling and rust removal, and the acid mist generated in the pre-treatment process will pollute the environment, and the waste acid needs further post-treatment; therefore, the use of environmentally friendly organic acids for rust removal It is imperative to replace the traditional pickling with chemical agent. In addition, compared with the linear reciprocating plating process, the circular continu...

Embodiment 2

[0049] The workpiece that present embodiment adopts is still building scaffolding, and the difference with embodiment 1 is that the coating material of this embodiment is not pure zinc but Galfan alloy (Zn-5Al%-Re), but its specific implementation is the same as embodiment 1.

[0050] According to the process flow, the raw material blanks are loaded in batches on the electric floor truck in the feeding area, and the loaded workpieces are transported by the electric floor truck to the bottom of the circular track in the feeding area, and are mounted by the electric hoist on the circular track. , followed by degreasing→water washing→pickling→water washing→plating help→drying→hot-dip galvanizing→water cooling→passivation→unloading and other operations; it is characterized in that there are four sets of electric hoists on the circular track. After the electric hoist is loaded and enters the next process, the next group of electric hoists automatically enters the loading area penda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com