Method for testing productivity profile of fluorescent nano proppant

A fluorescent nanometer and testing method technology, applied in construction and other directions, can solve the problems of unfavorable personnel, environmental safety, poor adaptability and selectivity, low test resolution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0029] The present invention will be described in detail below in conjunction with the figures.

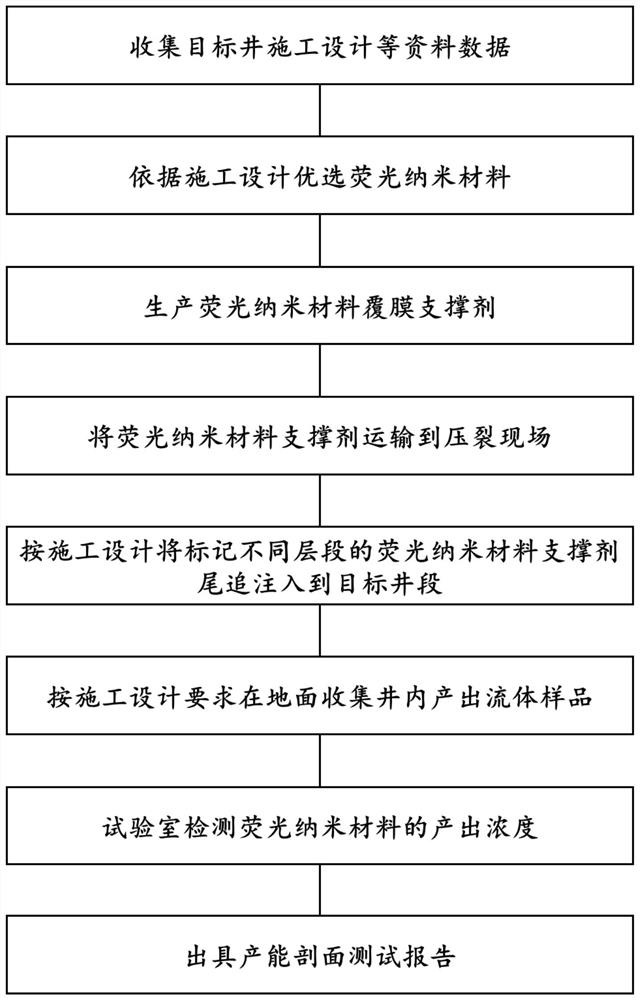

[0030] A method for testing a production capacity profile of a fluorescent nano-proppant, comprising the following steps:

[0031] Step 1: Collect data and data such as the construction design of the target well: such as well type, number of fracturing intervals, phase state that needs to be tested for productivity, sand addition amount for each section, proppant specifications, etc.;

[0032] Step 2: Optimizing fluorescent nanomaterials according to the construction design: such as varieties, specifications, etc.;

[0033] Step 3: Production of fluorescent nanomaterial-coated proppants: fluorescent nanomaterials are first synthesized with artificial polymers, and then coated on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com